Total Organic Carbon Analyzer (TOC)

What is TOC?

Total Organic Carbon Analyzer (TOC) is an instrument specially used to detect total organic carbon in deionized water such as purified water, water for injection, and ultrapure water. TOC analyzer is to oxidize total organic carbon in an aqueous solution to carbon dioxide and measures its content. The carbon content correspondence between carbon dioxide and total organic carbon is used to quantitatively measure total organic carbon in aqueous solutions. The instrument is controlled by the software installed on the computer and analyzes and processes the data. It has more complete functions, rich display content, convenient data query, and simple operation.

Features of TOC

- Powerful operating software based on method management and sample management to help customers improve work efficiency. The instrument is truly intelligent and automated.

- It fully complies with GMP requirements for computerized system verification, and FDA 21 CFR PART 11 requirements for electronic data integrity, electronic signatures, and audit trails.

- Using the ultraviolet photocatalytic oxidation method, no catalyst or carrier gas is needed. The ultraviolet lamp cooperates with the self-developed and designed titanium dioxide catalytic coating spiral tube to make the ultraviolet wavelength more stable and the oxidation efficiency higher, especially suitable for the determination of organic carbon content in pharmaceutical water.

- An external online monitoring device can be selected to meet the needs of online monitoring.

Applications of TOC

TOC can be used to detect the concentration of total organic carbon in purified water, water for injection, and high-purity water in the pharmaceutical industry; it can be used to detect TOC in ultra-pure water such as semiconductor industry, power plants, scientific research institutes, pharmaceutical industry, and chemical industry. Such as:

1. Drinking Water Treatment: Raw water sources such as lakes, streams, and reservoirs contain natural organic matter (NOM) from decaying plant or animal content. During disinfection, organics can combine with chlorine and other disinfectants to form harmful disinfection by-products (DBP). To comply with regulations, drinking water plants are held to strict DBP requirements and must measure TOC in raw and treated water to calculate the reportable TOC percent removal. Dissolved organic carbon content in drinking water can also affect odor, taste, and appearance.

2. Pharmaceutical industry: TOC monitoring is critical in ensuring that process water and final products are free from impurities. TOC can also indicate the presence of endotoxins, which can be harmful if consumed or used in medical products. Monitoring TOC levels in pharmaceutical water systems is necessary to meet regulatory requirements and to ensure the safety and efficacy of the final product.

3. Purified Water (PW): water that has been processed to remove impurities to low levels.

4. Water for Injection (WFI): water used as an excipient in the production of parenteral medications.

5. Ultrapure Water (UPW): water that has been purified to extremely low levels of impurities that must meet very strict specifications.

DRAWELL’s TOC Products

How to Choose the TOC?

- What’s the difference between online and offline models?

Online sampling directly on the water system, that is, the equipment is installed on the water system.

Offline means that water is sampled from the water system and sent to the laboratory for testing. The equipment is placed in the laboratory.

- Requirements for electrical conductivity

The TOC stipulates a detection limit of 50ppb or less; it is calibrated according to the method provided by the manufacturer; it meets the requirements of periodic system suitability testing.

- How to choose an autosampler?

The online model does not need to be equipped with an autosampler, and the offline model is shipped with the standard configuration of the sample bottle, a total of 18+2 bottles.

- Analytical method

Using the ultraviolet photocatalytic oxidation method, no catalyst or carrier gas is needed.

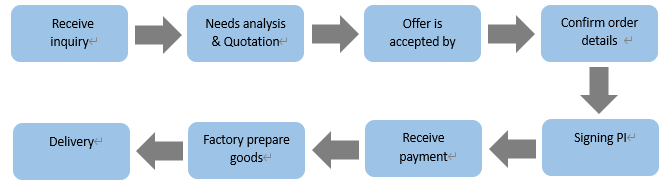

Order Process

Why Choose Us?

- Rich categories

- The products are market-oriented and exported to many countries in the world

- Perfect sales system, efficient and fast after-sales service

- On-time delivery rate reaches 100%

- High cost performance

FAQ

- Are you a factory or trading company?

– We are a factory.

- What is the MOQ?

-(1) Normally, MOQ is 1 piece.

-(2) If there is no stock, the general MOQ is a big difference between different products. But the quantity still can be negotiated.

- Can we ask for a sample from your company?

– Sample is available, but we do not provide free samples.

- Do you provide OEM service?

– OEM service is available with the customer’s brand.

- Which payment can be acceptable?

– We accept the payment by L/C, T/T, Paypal, Western Union, etc.

- How about your delivery time?

– Generally, it will take 7-15 working days after receiving your advance payment. Depend on the quantity.

- What after-sales service do you provide?

– We could provide Online instruction; Real-time support by video call or voice chat; During warranty time, we can send product accessories when you need them for free; Technical guidance is free and ready forever.

- How long is the warranty?

– 1 year. it can be negotiated if you need an extended warranty.

- If you have other questions, you can contact us through:

– Email: [email protected]

– Tel.: 008613320353102