Ultrasonic Homogenizers

The ultrasonic homogenizers are advanced laboratory instruments designed for efficient and precise sample processing. These homogenizers utilize high-frequency ultrasonic waves to break down, mix, and disperse particles in liquids, ensuring uniformity in a wide range of applications.

Ideal for cell disruption, nanoparticle dispersion, emulsification, and chemical synthesis, the ultrasonic homogenizers supplied by Drawell offer high efficiency, speed, and reproducibility. With customizable parameters like amplitude and pulse mode, they provide optimal control over the homogenization process, making them essential for research, pharmaceuticals, and industrial applications.

Features of Ultrasonic Homogenizers

- Adopt new software, centralized control by central microcomputer

- 7-inch TFT touch screen display

- Ultrasonic power stepping is continuously finely adjustable at 1%

- With pulse and continuous operation and test function

- Ultrasonic time, gap time, and total time can be accurate to 0.1 second

- With overload and time alarm function

- TC4 titanium alloy sealed transducer (JY98-IIIDN, JY99-IIDN)

* Note: Standard titanium alloy transducer, titanium alloy transducer has the advantages of high energy conversion rate, stability and durability, and suitable for long-term work compared with general transducers.

- Different models of instruments can be applied to the needs of different customers, with a crushing volume of 100μl-1200ml;

- Equipped with intelligent lifting soundproof box.

DRAWELL’s Ultrasonic Homogenizers

JY88-IIN JY96-IIN Ultrasonic Homogenizer

• Crushing Capacity:10-200/10-100ml

• Alarm: time, overload

JY92-IIN JY92-IIDN Ultrasonic Homogenizer

• Crushing Capacity:100ul-500ml/100μl-600ml

• Alarm: time, overload,temperature

JY98-IIIDN Ultrasonic Homogenizer

• Crushing Capacity 50-1000ml

• Alarm: time, overload, temperature

JY99-IIDN Ultrasonic Homogenizer

• Crushing Capacity 50-1200ml

• Alarm: time, overload, temperature

DW-IID Ultrasonic Homogenizer

• Capacity 100μl-600 ml

• Alarm: time, overload, temperature

DW08-III Uncontact Ultrasonic Cell Crusher

• Duty cycle: 0.1-99.9%

• Tank volume: 3L

• Temperature display: Yes

DW08-II Uncontact Ultrasonic Cell Crusher

• Duty cycle: 0.1-99.9%

• Tank volume: 1.5L

• Temperature display: Yes

How to Choose the Right Model of Ultrasonic Homogenizers

Articles published using Drawell series ultrasonic cell disruptors

[1] poly (butyl cyanoacrylate) and D-alpha-tocopheryl polyethylene glycol 1000 succinate for tumor-targeted delivery of morin hydrate [J].

International journal of nanomedicine, 2015, 10 (305-20).

[2] CHEN W, LI Q, CAO J, et al. Revealing the structures of cellulose nanofiber bundles obtained by mechanical nanofiber via TEM observation [J].

Carbohydrate polymers, 2015, 117 (950-6).

[3] ULUKO H, ZHANG S, LIU L, et al. Effects of thermal, microwave, and ultrasound pretreatments on antioxidative capacity of enzymatic milk protein concentrate hydrolysates [J]. Journal of Functional Foods, 2015, 18 (1138-46).

[4] WANG K, QI J, WENG T, et al. Enhancement of oral bioavailability of cyclosporine A: comparison of various nanoscale drugdelivery systems [J].

International journal of nanomedicine, 2014, 9 (4991-9).

Applications of Ultrasonic Homogenizers

Ultrasonic homogenizers are powerful and reliable mixers used in labs and industries for numerous applications. An ultrasonic homogenizer can be used for various applications, such as :

- Homogenization: Ultrasonic homogenizers can homogenize samples to create uniform and consistent mixtures.

- Dispersion: Ultrasonic homogenizers can be used to disperse solid particles in liquids to create stable suspensions. Ultrasonication is extraordinarily efficient in creating nano-dispersions.

- Emulsification: Ultrasonic homogenizers can be used to create stable emulsions and nanoemulsions by breaking up and dispersing immiscible liquids, such as oil and water.

- Cell Disruption: Ultrasonic homogenizers can break open cells to extract intracellular components such as proteins, nucleic acids, enzymes, and metabolites.

- Degassing: Ultrasonic homogenizers can be used to remove dissolved gases from liquids, such as degassing HPLC solvents or cooling fluids.

- Ultrasonically-assisted Chemical Reactions: Ultrasonic homogenizers can also be used for sonication-assisted chemical reactions, such as sonochemical synthesis, catalysis, or degradation.

Ultrasonic Homogenizer (Sonicator) Display

Pacing list of Ultrasonic Homogenizer

| Main Host | 1PC |

| Transducer | 1PC |

| Soundproof Box | 1PC |

| Power Cable | 2PCS |

| Special Wrench (for removing the Tip) | 1Pair |

| Operation Manual | 1PC |

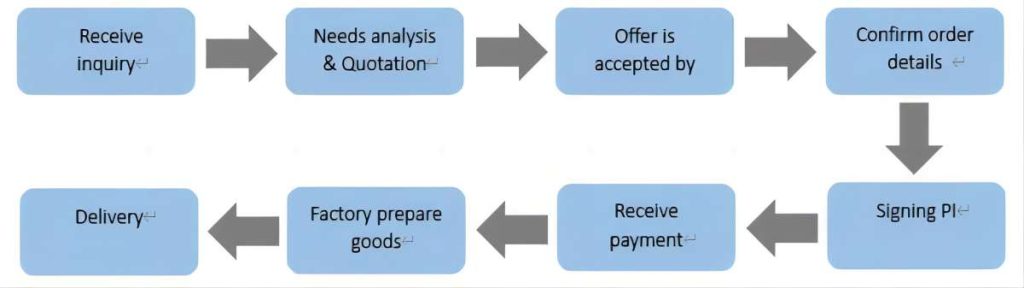

Order Process

Why Choose US?

- Rich categories.

- The products are market-oriented and exported to many countries in the world.

- Perfect sales system, efficient and fast after-sales service.

- On-time delivery rate reaches 100%.

- High cost performance.