Full Spectrum Direct Reading Spectrometer

What is Direct Reading Spectrometer?

Full Spectrum Direct Reading Spectrometer is a type of analytical instrument used for qualitative and quantitative analysis of the elemental composition of materials. This spectrometer is specifically designed to measure the entire emission spectrum produced by the atoms or ions of elements within a sample.

Features of Direct Reading Spectrometer

- High-performance optical system.

- Automatic optical path calibration.

- Single-plate lens design.

- Vacuum chamber integration.

- Vacuum anti-return oil technology.

- Open excitation platform.

- Jet electrode technology: unique argon gas path design, reducing the cost.

- The integrated gas circuit module.

- Fully digital excitation light source.

- High-speed data acquisition: The instrument uses high-performance CCD devices, ultraviolet coating technology, and high-performance FPGA, DSP, and ARM processors.

- Ether data transmission.

- Prefabricated working curve.

- The analysis speed is fast, and the element composition of all channels can be measured within 20 seconds.

- Multi-matrix analysis.

- The software is multi-language, fully compatible with the Windows system.

Application Areas of Direct Reading Spectrometer

Direct reading spectrometers are widely used in various analyses in metallurgy, foundry, machinery, scientific research, commodity inspection, automobile, petrochemical, shipbuilding, electric power, aviation, nuclear power, metal and non-ferrous smelting, processing and recycling industries.

Different Applications of Spectrophotometer

| Application | Spectrophotometer Type | Picture | Model |

| Gold in Ore, Metallurgy. Geology, Mining, Petroleum. Cement, Soil, Medicine, etc. |

AAS |  |

DW-AA320N |

| Alloy, Mineral, Precious Metal, RoHS, Catalyst etc. | XRF |  |

DW-NP-5010 |

|

EDX3600H | ||

|

TrueX 900 | ||

|

EDX800 | ||

| MaterialsAnalysis, Geology, Petrochemicals, Biology, Cement, Soil, Cosmetics, Food, etc. |

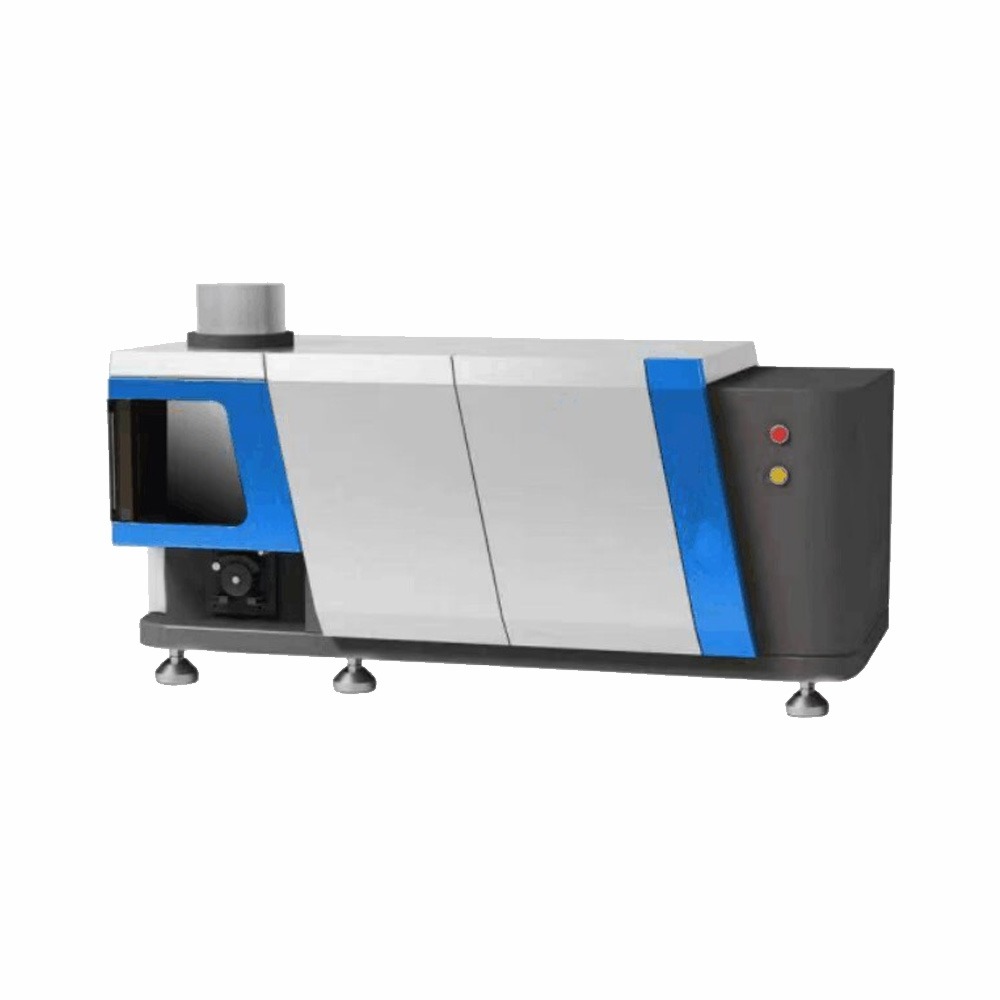

ICP-AES |  |

ICP700T |

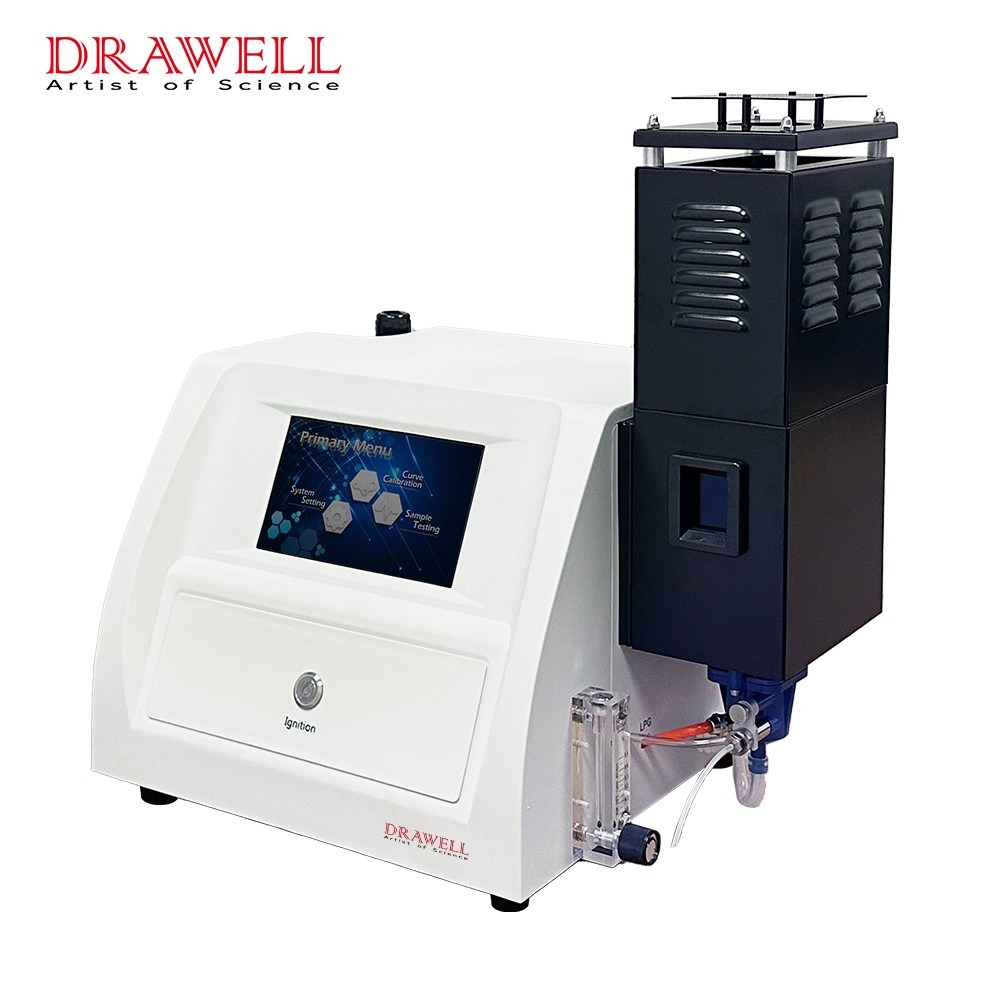

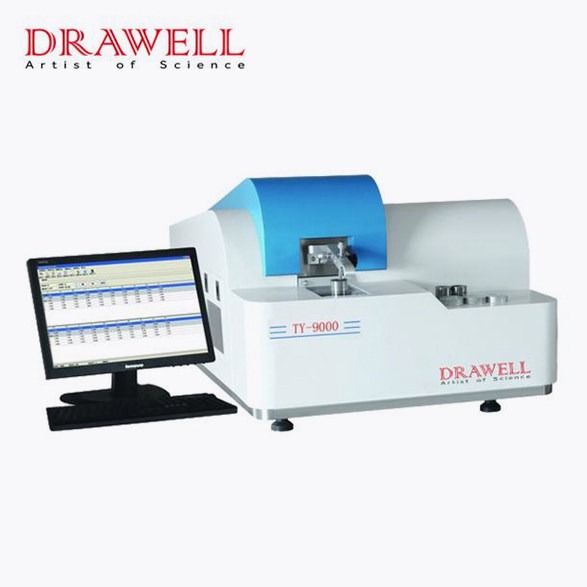

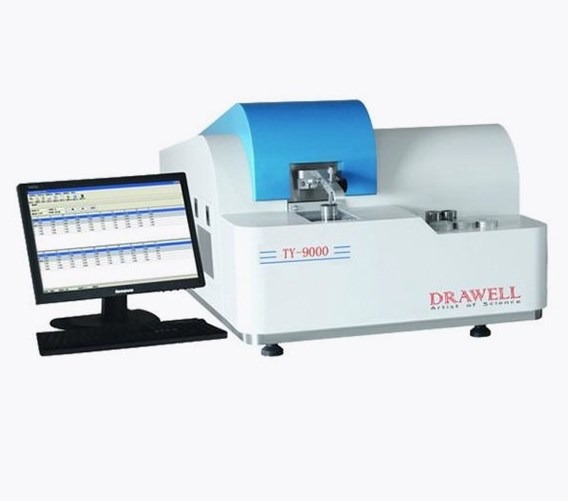

| Foundry, Steel, Metal Recovery, Smelting, MilitaryAerospace, etc. | Full Spectrum Direct Reading Spectrometer |  |

DW-TY9000 |

Why Choose Us?

“Multiple suppliers” have always been an issue in the procurement process. Drawell as a one-stop laboratory equipment and scientific instruments supplier, can perfectly solve this problem. In addition to manufacturing our own equipment, we also represent other laboratory equipment. Our product lines are rich and diverse at competitive prices. Provide one-stop service to customers.

User Training – Training by Drawell skilled engineers about installation, debug tests, technical services, etc. It can happen in our factory in China, or at the site in the customers’ country. Cost depends on where and when the training happens.

To discuss the problem and get it resolved, online chats, real-time video calls, and remote guidance. For the after-sales stage, our online technical guidance is free and ready forever.

1 year free official warranty, including repairing quality-damaged parts, and offering replacements of selected parts (shipping cost is extra). 5% of the product price is charged for extending the warranty before the end of the official warranty.