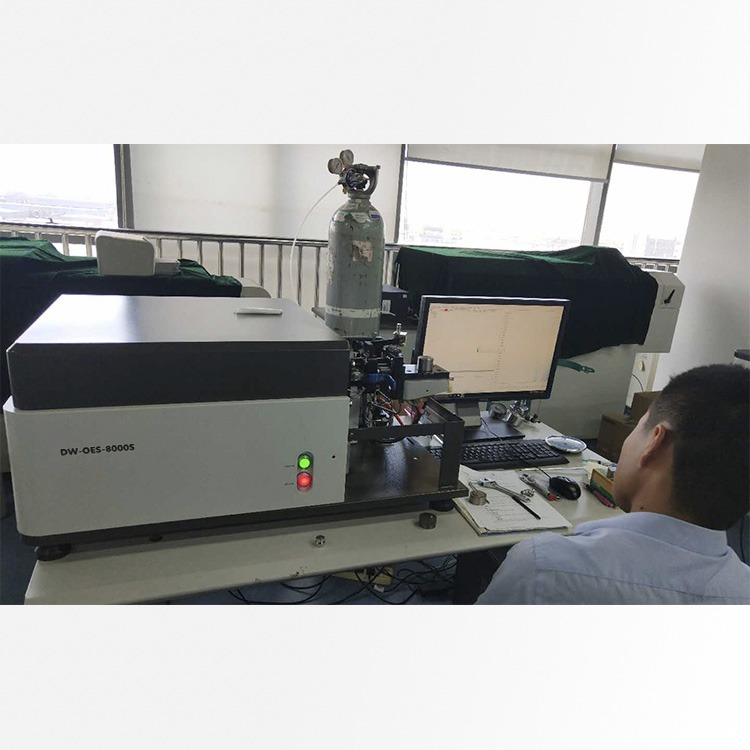

DW-OES 8000S Direct-reading Optical Emission Spectrometer (for Metal alloy/Stainless steel)

- A compact structure requires low laboratory space

- Around-the-clock working with premium stability and reliability

- Fast detection with a single test less than 30 seconds

- Easy to use and maintain, and little professional knowledge demanded for operators

- Original factory-set software, accurate test data, and complete alloy grades

- Configured with standard samples to periodically calibrate the instrument

- No chemical reagents to make the test process safe and environmental-friendly

Functions of DW-OES 8000S Direct-reading Optical Emission Spectrometer

DW-OES8000S adopts a CMOS detector with full-spectrum test technology to test all spectral lines within the wavelength range. Featuring easy configuration as well as addition of test matrix, channel, and analysis program, the instrument is compact in size, easy to maintain and good for laboratory placement. It is a general-purpose instrument for comprehensively testing elements of steel and non-ferrous metal materials.

Direct-reading spectrometer is widely used in element content analysis in iron and steel, non ferrous metal materials, which is fast, accurate, stable, and as dozens of elements are analyzed simultaneously, the instrument meets the needs of industrial research and development, process control, incoming inspection, product sorting and other aspects.

Technical Parameters of DW-OES 8000S Direct-reading Optical Emission Spectrometer

| Light chamber design – Special materials to ensure that the light chamber deforms to minimum | ||

| Pasing Longge structure with diameter | Roland circle being 400mm | |

| Wavelength range | 134-680nm | |

| Pixel resolution | 10pm | |

| Constant temperature | 32.5 ±0.5°C | |

| Concave Grating | ||

| Engraved line density | 2400l/mm | |

| Primary spectral line dispersion rate | 1.04nm/mm | |

| Working Conditions | ||

| Working temperature | 15-30 °C | |

| Relative humidity | ≤70% | |

| Power supply | 220±5V, single-phase 50Hz, grounding resistance <10 | |

| The laboratory is expected to have no vibration, dust, strong electromagnetic interference, strong airflow, or corrosive gas. | ||

| Excitation light source | ||

| High energy plasma spark light source technology | High-energy pre-sparking technology (HEPS) | |

| Frequency | 100-1000Hz | |

| Excitation Platform | ||

| 3mm analysis spacing on sample platform | Spray electrode technique | |

| Dimension/Weight | ||

| H435mm, L900mm, W 600mm | 120 kg | |

| Power | ||

| Maximum power | 1500 W | |

| Standby power | 70 W | |

| Detector | ||

| High-performance linear array CMOS | ||

| Analysis time | ||

| 30 seconds or less, depending on sample type | ||

Software

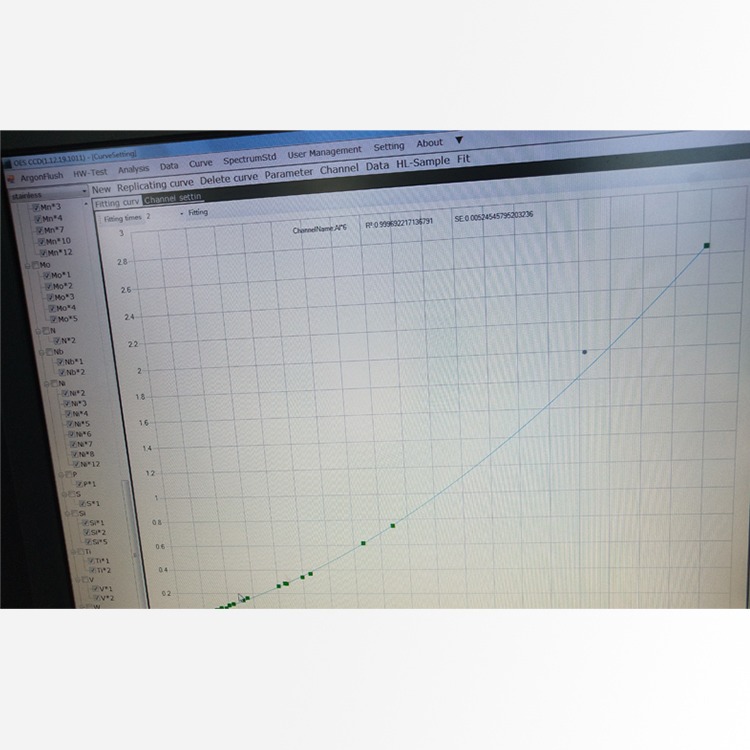

- Polynomial correction method to calculate the concentration ratio

- Matrix correction

- Intensity standardized correction

- Material grade type re-calibration

- Automatic correction of the interference between the spectral lines of the elements

- Recognition of grade library

- One-key position correction

- One-key printing function

- The test results are output in different formats

- National Standard Sample Library

Accessories

- — High-purity argon with a purity of over 99.999%.

- — Alternating current UPS-1 KVA.

- — Spectral grinding machine for steel, nickel alloy and other samples.

- — Small lathes for making samples such as aluminum, copper, zinc, magnesium alloy, etc.

- — Air conditioner should be supplied based on the area of laboratory.

Advantages of DW-OES 8000S Direct-reading Optical Emission Spectrometer

1. Full spectrum detection of a wide range of metals and elements.

CMOS detector with full spectrum test technology, able to test all kinds of metal elements for their spectral lines, achieving multi-matrix, multi-element test easily. It is very convenient to configure and add test matrix, channel and analysis program, which facilitates fast addition of test elements and analysis program at the customer’s premise after delivery.

2. Professional Test Solutions

Drawell Instrument offers mature testing solutions to users analyzing steel and nonferrous metal materials by virtue of its long-term accumulated experience in testing technology and service. Analysis programs are based on the classification of material element content to meet various common testing requirements of users. It is calibrated by international and national standard samples, and fitted and calibrated by professional instrument software.

3. Core components supplied by top international manufacturers

Spectral dispersion part or grating is manufactured by JY, France, which guarantees excellent spectral resolution. Spectral detector or high performance CMOS is manufactured by Hamamatsu, Japan, which ensures sensitive spectral line detection and low noise.

4. Excellent light chamber vacuum system

The vacuum chamber is precisely designed and processed, with excellent airtight performance, which provides high vacuum environment for the light path. Therefore, there is no need to start vacuum pump frequently, resulting in minimum power consumption and better chances to keep the light chamber clean.

Test Examples Using DW-OES 8000S Direct-reading Optical Emission Spectrometer

1. Sample taking

Sampling can be divided into melt sampling and finished product sampling. Melt sampling injects liquid metal into a mold to solidify into a lump sample. Finished product sampling requires evaluation of the size, shape of the sample to decide whether to cut it.

2. Reference standards

GB/T 20066-2006 一 Steel and iron—Sampling and preparation of samples for the determination of the chemical composition.

GB/T 5678-2013 Method for Sampling Casting Alloys for Spectochemical Analysis.

3. Sample Pretreatment

High-hardness metals (such as steel, nickel alloys, cobalt alloys) need to be polished with a spectroscopic grinder, and low-hardness metals (such as aluminum alloy, copper alloy, zinc alloy, magnesium alloy) should be lathed with the test surface to make it flat, smooth, and with consistent scratches.

4. Sample testing

Place the sample on the sample excitation platform, and operate on the computer software to start the test. After the test is completed, contents of all configured elements will be displayed. Each single test is usually less than 30 seconds. It is generally recommended testing the same sample three times.

5. Test Data Saving

Test results can be saved in the software database or printed directly.

Example of Test Results

Low-alloy steel

| Element | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

| Std valu | 0.499 | 2.140 | 0.798 | 0.029 | 0.021 | 0.974 | 1.970 | 0.830 | 0.303 |

| Measured value | 0.491 | 2.168 | 0.818 | 0.027 | 0.019 | 0.953 | 1.939 | 0.820 | 0.291 |

| Element | V | Ti | Al | Nb | W | B | Co | Zr | |

| Std valu | 0.469 | 0.082 | 0.027 | 0.124 | 1.530 | 0.0047 | 0. 238 | 0.051 | |

| Measured value | 0.475 | 0.083 | 0.025 | 0.127 | 1.501 | 0.004 | 0. 230 | 0.055 |

Stainless steel YSBS11378A-2008

| Element | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

| Std valu | 0.066 | 0.760 | 1.160 | 0.030 | 0.0091 | 17.490 | 8.230 | 0.205 | 0.355 |

| Measured value | 0.066 | 0.790 | 1.180 | 0.027 | 0.007 | 17.573 | 8.173 | 0. 189 | 0.344 |

| Element | V | Ti | Al | Nb | W | Co | |||

| Std valu | 0.061 | 0.006 | 0.014 | 0.011 | 0.021 | 0.099 | |||

| Measured value | 0.059 | 0.007 | 0.018 | 0.010 | 0.029 | 0.094 |

Aluminum silicon alloy E513E

| Element | Si | Fe | Cu | Mn | Mg | Ni | Zn | Ti | Pb | Sn | Sr |

| Std valu | 12.64 | 0.212 | 2.070 | 0.540 | 0.753 | 0.066 | 0.216 | 0.042 | 0.074 | 0.021 | 0.062 |

| Measured value | 12.715 | 0.190 | 2.031 | 0.528 | 0.737 | 0.068 | 0.211 | 0.040 | 0.078 | 0.020 | 0.064 |

Low-alloy aluminum E423B

| Element | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti |

| Std valu | 1.280 | 0.432 | 0.522 | 0.234 | 0.911 | 0.340 | 0.030 | 0.091 | 0.028 |

| Measured value | 1.261 | 0.417 | 0.513 | 0.226 | 0.893 | 0.321 | 0.026 | 0.092 | 0.026 |

Brass 31XB21

| Element | Cu | Zn | Sn | Pb | Fe | Ni | Al | Si | Mn |

| Std valu | 69.6793 | 29.500 | 0.132 | 0.120 | 0.129 | 0.107 | 0.121 | 0.147 | 0.0647 |

| Measured value | 69.781 | 29.403 | 0.121 | 0.101 | 0.124 | 0.112 | 0.134 | 0.135 | 0.061 |

| Zinc aluminum 43XZ4 | Magnesium aluminum alloy E2612 | ||||||||||||||

| Element | Al | Cu | Fe | Mg | Pb | Cd | Sn | Element | Al | Zn | Mn | Si | Fe | Cu | Ni |

| Std valu | 4.760 | 3.210 | 0.064 | 0.043 | 0.0024 | 0.0025 | 0.030 | Std valu | 7.180 | 2.990 | 0.339 | 0.097 | 0.013 | 0.087 | 0.0045 |

| Measured vali | 4.723 | 3.168 | 0.052 | 0.043 | 0.0029 | 0.0021 | 0.026 | Measured value | 7.116 | 2.942 | 0.359 | 0.090 | 0.017 | 0.082 | 0.002 |

Inconel B.S.600C

| Element | C | Mn | Si | Cr | Fe | Mo | W | Al | Ti |

| Std valu | 0.072 | 0.500 | 0.390 | 15.620 | 9.300 | 0.027 | 0.003 | 0.200 | 0.210 |

| Measured value | 0.058 | 0.469 | 0.412 | 15.559 | 9.212 | 0.0246 | 0.007 | 0.182 | 0.242 |

| Element | Cu | Co | Nb | V | Mg | ||||

| Std valu | 0.040 | 0.040 | 0.014 | 0.022 | 0.002 | ||||

| Measured value | 0.043 | 0.038 | 0.012 | 0.025 | 0.004 |