In the realm of scientific research, the extraction of fat from various substances has long been a tedious and time-consuming process. Whether for nutritional analysis, quality control in food production, or environmental monitoring, the efficiency and accuracy of fat extraction are paramount. Traditional methods, while effective, often demand extensive labor and prolonged periods, hindering productivity and impeding progress.

However, a revolutionary innovation has emerged in the form of the Auto Soxhlet Fat Extractor, promising to transform the landscape of fat extraction. By integrating automation and precision, this cutting-edge device offers unparalleled efficiency, consistency, and convenience in the extraction process. In this article, we delve into the principles, benefits, and applications of this groundbreaking technology, heralding a new era in fat extraction methodologies.

From Manual to Marvel: Embracing Automation

The traditional Soxhlet extractor involves manually refilling solvent reservoirs, monitoring extraction cycles, and collecting extracted fats – a tedious and error-prone process. The auto Soxhlet fat extractor takes the reins, injecting automation into every step. Programmable controls allow for precise cycle timings and solvent replenishment, while integrated sensors monitor temperature and solvent levels. This automation not only frees up valuable time for technicians but also minimizes human error, leading to consistent and reproducible results.

How does Auto Soxhlet Fat Extractor Work?

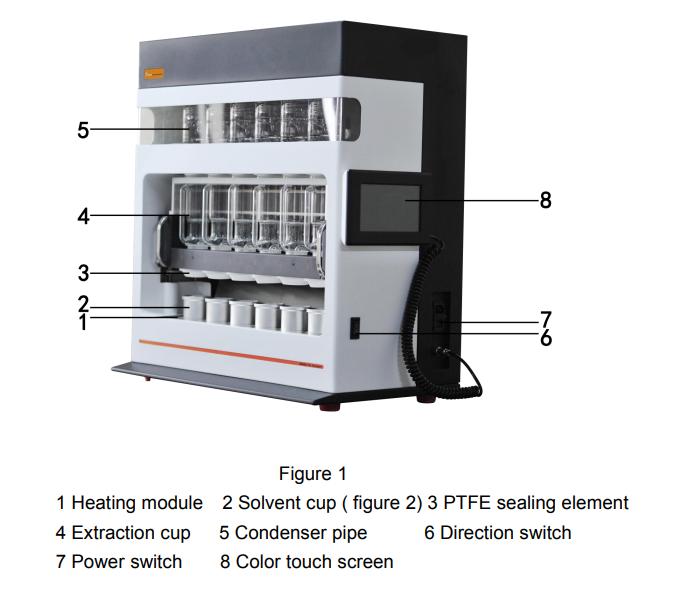

The auto Soxhlet fat extractor builds upon the traditional Soxhlet method, infusing it with automation to deliver unparalleled efficiency and accuracy. Here’s a detailed breakdown of its operation:

1. Preparation for Extraction:

Sample Prep: The process begins with the loading of the solid sample containing the fat to be extracted into the Soxhlet extraction chamber. The sample is typically ground or homogenized to increase surface area, facilitating efficient extraction. After meticulously weighing the sample, and then placing it in a thimble made of filter paper. This thimble acts as a vessel for your sample, allowing the solvent to pass through while retaining the extracted fats.

Solvent Selection: Choosing the right solvent is crucial. Typically, a suitable organic solvent is chosen based on its ability to dissolve the fat component while being immiscible with water and other impurities present in the sample. Common solvents include hexane or petroleum ether are used due to their affinity for fats and inability to dissolve the filter paper thimble. The chosen solvent is added to the designated reservoir of the extractor.

2. The Automated Extraction

Extraction Cycle Initialization: The Auto Soxhlet Fat Extractor initiates the extraction cycle by adding a precise volume of solvent to the extraction chamber. This volume is carefully controlled to ensure optimal extraction efficiency while minimizing solvent consumption.

Heating and Extraction: The heating element controlled by precise programmable settings. This element heats the solvent in the flask until it reaches its boiling point. As the solvent vaporizes, it rises through the extraction chamber, carrying fat molecules with it. The fat is dissolved in the solvent, forming a fat-solvent mixture.

Condensation and Collection: As the solvent boils, it transforms into vapor and ascends the condenser. This condenser, acting like a cooling chamber, forces the vapor to condense back into liquid form. The condensed solvent then drips back into the extraction chamber, where it continues to extract fat from the sample in a continuous cycle. These extracted fats then travel down the thimble and accumulate in the flask below. The cycle continues as the hot solvent continuously rises, condenses, and drips, effectively rinsing and extracting the fats.

3. Solvent Recycling

As the extraction cycle progresses, the Auto Soxhlet Fat Extractor recovers the solvent from the extraction chamber. The solvent vapors are condensed and collected in a separate flask or reservoir, ready for reuse in subsequent extraction cycles. This solvent recovery process minimizes solvent waste and reduces operating costs.

4. Control and Monitoring

Throughout the extraction process, the Auto Soxhlet Fat Extractor maintains precise control over key parameters such as temperature, solvent flow rate, and extraction time. Advanced sensors and monitoring systems ensure optimal extraction conditions, maximizing efficiency and reproducibility while minimizing the risk of sample degradation or solvent loss.

5. Completion and Analysis:

Once the extraction cycle is complete, the extracted fat, now dissolved in the solvent, is collected in a separate container. The fat content can then be quantified using analytical techniques such as gravimetric analysis, chromatography, or spectroscopy, depending on the specific requirements of the application.

Advantages and Applications of Auto Soxhlet Fat Extractor

The Auto Soxhlet Fat Extractor offers numerous advantages over traditional methods of fat extraction, making it a preferred choice for researchers, analysts, and industries. Some of the key advantages include:

- Automation: One of the most significant advantages of the Auto Soxhlet Fat Extractor is its automation capabilities. The device automates key steps in the extraction process, reducing the need for manual intervention and minimizing operator error. This automation leads to increased efficiency and throughput, allowing for the extraction of multiple samples simultaneously without sacrificing accuracy or reproducibility.

- Precision and Consistency: The Auto Soxhlet Fat Extractor maintains precise control over extraction parameters such as temperature, solvent flow rate, and extraction time. This precision ensures consistent results across multiple extraction cycles and minimizes variability between samples. Researchers and analysts can have confidence in the reliability and accuracy of their fat extraction data.

- Time Savings: Compared to traditional Soxhlet extraction methods, which can be time-consuming due to manual handling and prolonged extraction times, the Auto Soxhlet Fat Extractor offers significant time savings. Its automated operation allows for faster extraction cycles, reducing overall processing time and increasing laboratory productivity.

- Reduced Solvent Consumption: The Auto Soxhlet Fat Extractor optimizes solvent usage by recycling solvent through the extraction cycle and recovering it for reuse. This reduces solvent consumption and minimizes waste, resulting in cost savings and environmental benefits. Additionally, the device’s closed-loop system helps maintain a controlled environment, further minimizing solvent emissions and ensuring user safety.

- User-Friendly Interface: The Auto Soxhlet Fat Extractor is designed with a user-friendly interface that simplifies operation and monitoring of the extraction process. Intuitive controls and digital displays allow users to easily set extraction parameters, monitor progress, and troubleshoot any issues that may arise during operation.

- Safety Features: Modern safety features incorporated into the Auto Soxhlet Fat Extractor enhance user safety and mitigate risks associated with solvent handling and extraction procedures. These features may include temperature alarms, pressure sensors, and automatic shutdown mechanisms to prevent overheating or solvent spills.

- Versatility: The Auto Soxhlet Fat Extractor is versatile and can be used for a wide range of applications beyond fat extraction, including the extraction of other analytes and compounds from various sample matrices. Its flexibility makes it a valuable tool for researchers and analysts working in diverse fields such as food science, environmental analysis, pharmaceuticals, and more. Here are some detailed applications:

| Application | Description |

| Food Analysis | Nutritional Labeling: Determine fat content for accurate labeling |

| Quality Control: Assess fat content in raw materials and finished products | |

| Research and Development: Investigate fat composition and optimize formulations | |

| Environmental Analysis | Pollution Monitoring: Assess pollution levels and identify contaminants |

| Toxicology Studies: Analyze lipophilic pollutants and assess toxicity | |

| Pharmaceuticals and Cosmetics | Drug Formulation: Determine fat content for drug stability and bioavailability |

| Cosmetic Formulation: Analyze fat content for skincare and makeup products | |

| Oil and Fat Processing Industries | Oil Extraction: Assess fat content in oils and fats for quality control |

| Biodiesel Production: Determine lipid content in biomass feedstocks for biodiesel production | |

| Academic and Research Institutions | Chemical Analysis: Conduct fundamental and applied research in chemistry and biochemistry |

| Method Development: Develop and validate fat extraction methods for diverse research applications |

Overall, the Auto Soxhlet Fat Extractor offers numerous advantages that make it an indispensable tool for laboratories and industries requiring efficient, precise, and reliable fat extraction capabilities. Its automation, precision, time savings, solvent efficiency, user-friendly interface, safety features, and versatility combine to streamline the extraction process and drive scientific advancements across multiple disciplines.

Different Types and Features

The versatility of the auto Soxhlet fat extractor extends beyond its applications – it also comes in various configurations to cater to diverse needs and preferences. Here are two main types:

- Single-position extractors: These extractors can only handle one sample at a time. They are typically smaller and more affordable than multi-position extractors.

- Multi-position extractors: These extractors can handle multiple samples simultaneously, which can save time and improve efficiency. They are typically larger and more expensive than single-position extractors.

In addition to the number of positions, Auto Soxhlet Fat Extractors can also be classified by the following features:

- Solvent recycling: Some extractors have built-in solvent recycling systems, which can help to reduce solvent waste and costs.

- Temperature control: Some extractors have temperature control systems, which can be important for extracting certain types of fats.

- Data acquisition: Some extractors have data acquisition systems, which can be used to track the progress of the extraction and record the results.

When choosing an Auto Soxhlet Fat Extractor, it is important to consider your specific needs and budget. If you only need to extract a small number of samples occasionally, a single-position extractor may be sufficient. However, if you need to extract a large number of samples on a regular basis, a multi-position extractor may be a better choice.

Conclusion

In conclusion, the advent of the Auto Soxhlet Fat Extractor represents a significant milestone in scientific instrumentation. Its capacity to streamline fat extraction procedures while ensuring reproducibility and accuracy holds immense promise across diverse fields of research and industry. As laboratories and facilities seek to optimize their workflows and enhance productivity, the Auto Soxhlet Fat Extractor emerges as an indispensable tool.

For researchers, food producers, and environmental analysts alike, partnering with a reliable soxhlet extractor supplier becomes imperative. Access to state-of-the-art equipment, coupled with the right technology and support, you can unlock a new era of fat analysis. Please feel free to contact Drawell for any laboratory equipment needs.