Centrifuges are ubiquitous laboratory tool that utilizes centrifugal force to separate particles and molecules within a liquid sample. They are used in a variety of industries and applications, ranging from medical research and drug development to food and beverage production. There are several different types of centrifuges available, each with unique features and applications. In this article, we will explore the different types of centrifuges and their applications, helping you to determine the best centrifuge for your specific needs.

Different Types of Centrifuges and Their Applications

There are several different types of centrifuges, each with its own unique design and application. Here are some of the most common types of centrifuges and their uses:

- Low Speed Centrifuge

A low-speed centrifuge typically spins at speeds between 1,000 and 10,000 rpm and is used for general purpose sample preparation, such as separating blood components or collecting bacterial cells.

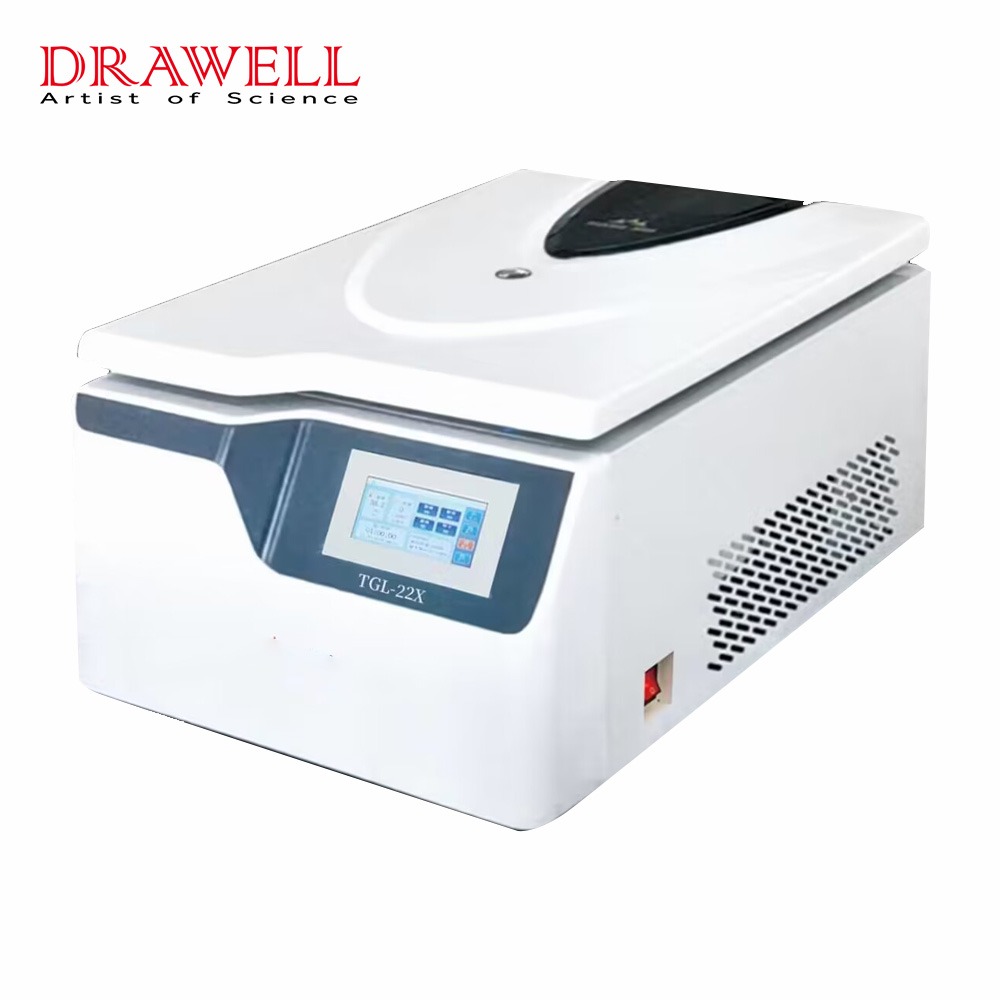

- High Speed Centrifuge

A high-speed centrifuge can spin at speeds of up to 20,000 rpm and is commonly used for separating larger particles such as cells, organelles, and subcellular fractions.

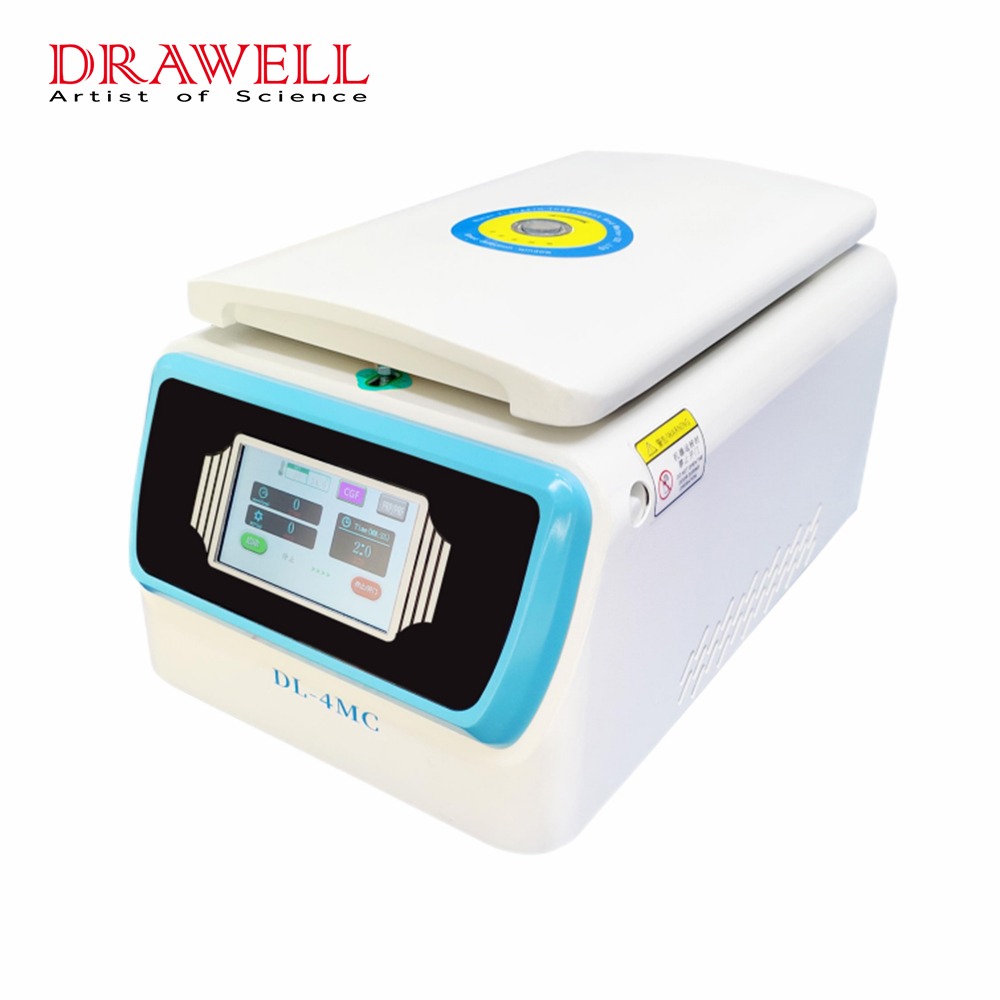

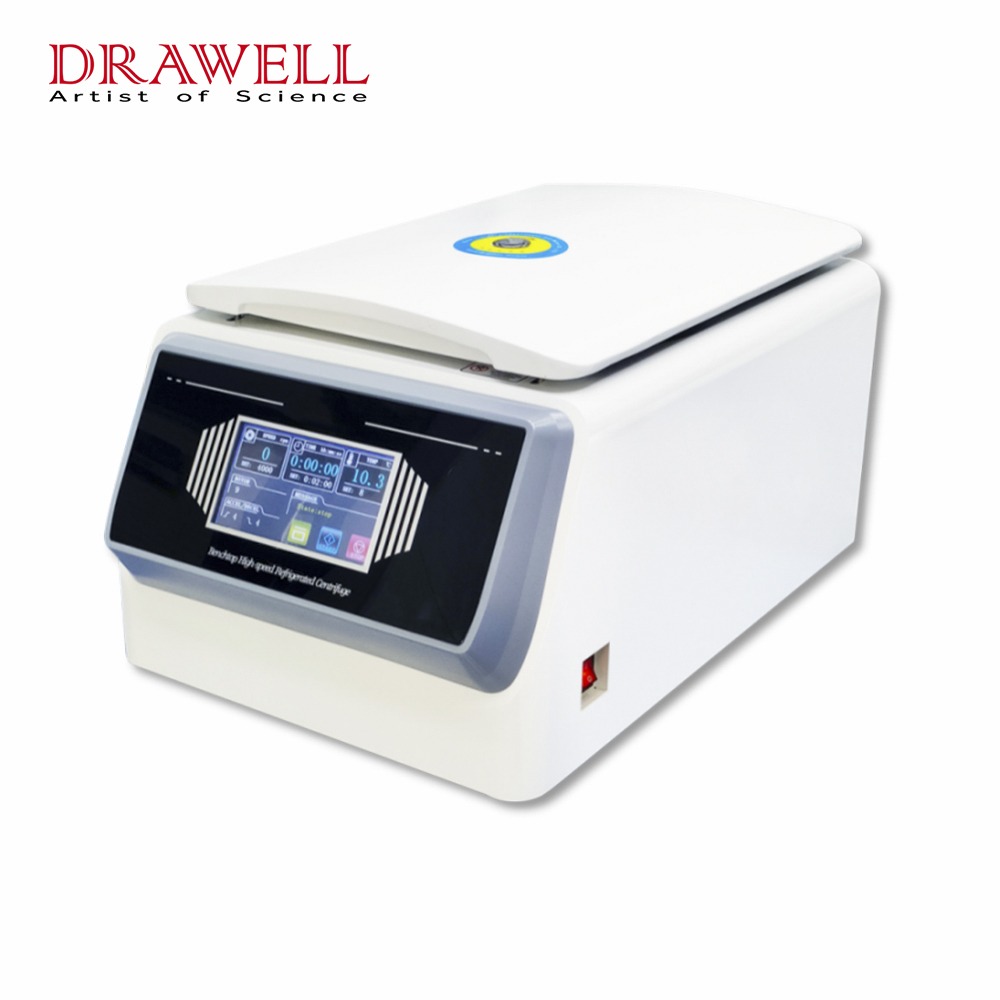

- Refrigerated Centrifuge

A refrigerated centrifuge is a type of centrifuge that is equipped with a cooling system, typically using a compressor or thermoelectric cooling technology. This type of centrifuge is able to maintain a set temperature during operation, making it ideal for separating cells, proteins, and other biomolecules at low temperatures, such as isolating DNA or RNA from a blood sample or separating different types of cells based on their density.

- Ultracentrifuge

An ultracentrifuge is a high-speed centrifuge that can spin at speeds of up to 100,000 rpm or more. It is used for separating and purifying smaller particles such as DNA, RNA, and proteins.

- Microcentrifuge

A microcentrifuge is a small, low-speed centrifuge used for separating small volumes of samples, typically less than 2 mL.

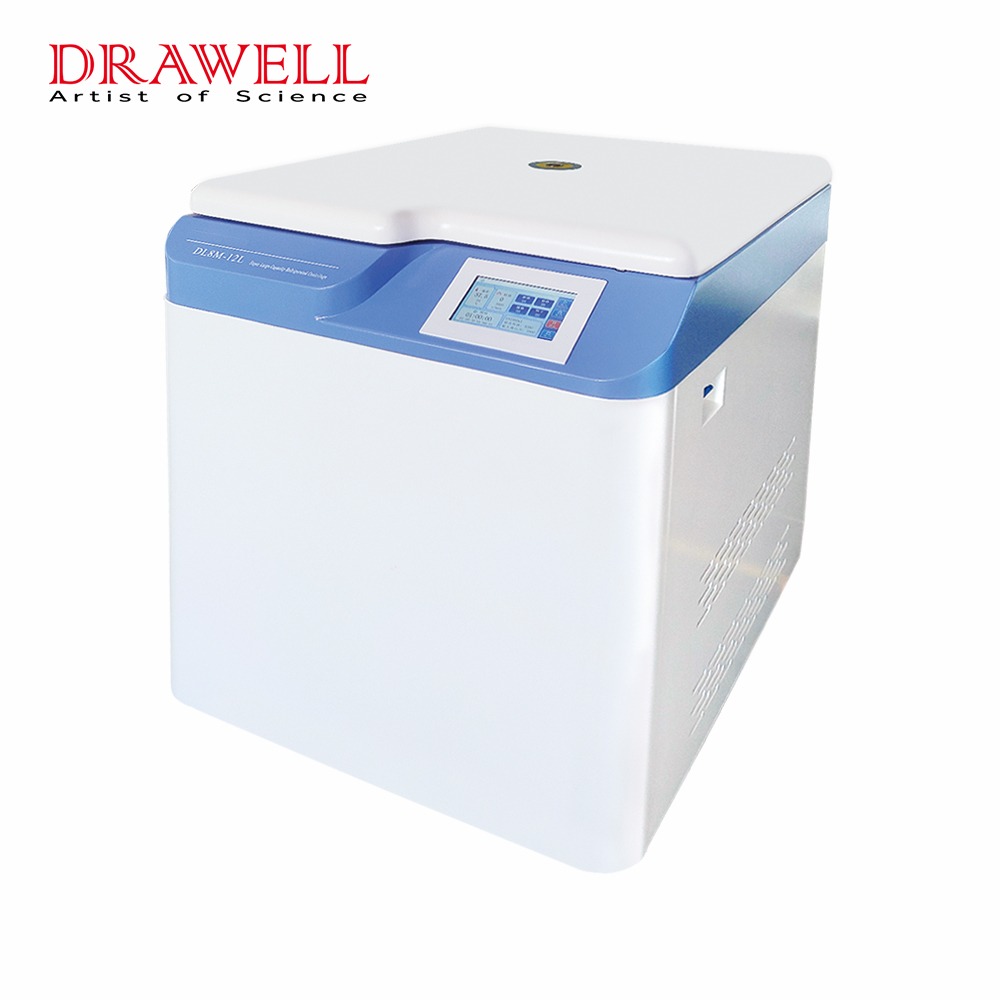

- Preparative Centrifuge

A preparative centrifuge is used for large-scale separation and purification of samples, such as proteins or viruses, and is capable of processing large volumes of material.

- Analytical Centrifuge

An analytical centrifuge is used for measuring the properties of particles, such as size, shape, and density, and is commonly used in biopharmaceutical research and development.

- Zonal Centrifuge

A zonal centrifuge is used for separating particles based on their molecular weight or density and is commonly used in the separation of proteins and nucleic acids.

- Isopycnic Centrifuge

An isopycnic centrifuge is used for separating particles of different densities based on their buoyant density and is commonly used in the separation of DNA and RNA.

Overall, centrifuges are versatile laboratory equipment that is essential for a wide range of research, diagnostic, and industrial applications. The type of centrifuge used depends on the specific application and the properties of the sample being processed. So how to select the right centrifuge for a specific application?

How to Select the Right Centrifuge for a specific Application?

Selecting the right centrifuge for a specific application requires careful consideration of several factors. Here are some key considerations that can help guide your selection process:

- Speed and capacity

The maximum speed and capacity of a centrifuge are important factors to consider, as they determine how much material can be processed and how quickly. Be sure to choose a centrifuge that can handle the volume and type of samples you plan to process.

- Type of rotor

Centrifuge rotors come in different designs and sizes, each with its own advantages and limitations. Consider the type of rotor that is best suited for your application, based on factors such as the size and type of particles you are separating, the volume of the sample, and the speed required.

- Temperature control

Depending on your application, you may need a centrifuge that can maintain a specific temperature during the separation process. Consider whether a refrigerated or heated centrifuge is necessary for your application.

- Sample compatibility

Some samples are sensitive to certain types of centrifugation, such as high speeds or prolonged exposure to heat. Be sure to choose a centrifuge that is compatible with the type of samples you plan to process.

- Ease of use

Consider the user-friendliness of the centrifuge, including features such as programmable settings, digital displays, and safety features. This can help ensure that the centrifugation process is efficient and safe.

- Maintenance and cost

Consider the cost of the centrifuge, as well as the cost of maintenance and replacement parts. Choose a centrifuge that fits within your budget and is easy to maintain and repair.

In conclusion, centrifugation is a critical technique in many industries, allowing for the separation and purification of a wide range of materials. Whether you are conducting medical research, producing pharmaceuticals, developing cosmetic products, or working in any other field that requires the separation and purification of materials, selecting the right centrifuge is key to achieving accurate and reliable results. By understanding the capabilities of each type of centrifuge and its specific applications, you can make an informed decision and choose the centrifuge that is best suited to your needs.