X-Ray Fluorescence Spectrometer (XRF)

What is X-Ray Fluorescence Spectrometer?

X-ray fluorescence (XRF) uses X-rays and fluorescence technology. When primary X-rays are irradiated on the sample to be tested, the secondary X-rays generated are called X-ray fluorescence. The composition and energy of the substance are analyzed by analyzing the wavelength and energy of the fluorescence.

XRF has the advantages of a simple spectrum, no damage to samples, simple operation, rapid determination, etc., and is widely used in geology, metallurgy, mining, non-ferrous metals, marine, biochemical, environmental, petrochemical, commodity inspection, electronics, public security, and archaeology, Refractory materials, and building materials industry, and other fields.

Handheld XRF

Handheld XRF analyzer using an integrated group of instrument components that are sealed in an ergonomically designed, lightweight body.

Desktop XRF

The high-performance desktop XRF is equipped with globally advanced analysis technology, an intelligent vacuum system, and developed electronic technology. Combined with a low-energy tube vacuum system and low background technology. It efficiently reduces testing interference and improves energy resolution of Mg, Al, Si P, and other light elements in geology and minerals, and accordingly an ideal choice for quality control in large and middle-scaled enterprises

Features of XRF Spectrometer

Handheld XRF

- Small, light, and easy to carry.

- High-speed processing chip, resulting in even faster analysis.

- High-performance X-ray Tube, super-high detection resolution.

- One-touch operation, easy to operate by non-technical users.

- Nondestructive testing (NDT).

- Drawell analysis software.

- Power saving can automatically switch to standby mode.

Desktop XRF

- High precision, fast testing speed, easy operation, etc.

- Bear several testing analysis modes, including alloy soil precious, and RoHS.

- Testing samples can be solids, liquids, and powders.

- Highly efficient super-thin window-ray light tube, which is specially developed for mineral testing, reaches the international advanced level.

- Automatic switch of collimator and filter according to different samples, eliminating the troublesome manual operation.

- Software protection: Automatic shut-down of software program when opening the cover during testing.

- Principle of Wavelength Dispersive Spectroscopy.

Specifications of XRF

| Type | Picture | Model | Main Application | Detector |

| Handheld XRF |  |

TrueX 800 | Alloy application | BOOST Si-PIN |

| TrueX 860 | 5 more element than TrueX 800 : Mg Al Si P S | SDD | ||

| TrueX 900 | Mineral application | BOOST Si-PIN | ||

| TrueX 960 | 5 more element than TrueX 900 : Mg Al Si P S | SDD | ||

| TrueX RoHS | RoHS application | BOOST Si-PIN | ||

| TrueX Gold | Precious metal application | BOOST Si-PIN | ||

|

DW-EX 5000 | Alloy application, Simultaneous detection of Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ga, Ge, Zr, Nb, Mo, Ru, Rh, etc. | Fast SDD | |

| DW-EX 7000 | Mineral application, Simultaneous detection ofAg, In, Sn, Sb, Hf, Ta, W, Re, Pt, Au, Pb, Bi, Mg, Al, Si,etc. | Fast SDD | ||

|

DW-1688、DW-1688S | Alloy application | High-resolution Si-Pin detector | |

|

DW-980、DW-980S | Catalyst application | KETEK ultra-large SDD detector | |

|

DW-8000 | Gold application | High-resolution Si-Pin detector | |

|

DW-600、DW-600S | Mineral application | Moxtek Si-pin (6mm²) Amptek Si-pin (25mm²) KETEK SDD detector(DW-600S) |

|

|

DW-500、DW-500S | Soil application | High-resolution SI-PIN detector | |

| Desktop XRF |  |

DW-NP-5010 | Any element from Na(11)-U(92) | Si-PIN or SDD detector |

Applications of X-Ray Fluorescence Spectrometer

- Environmental protection: analysis of heavy metals in soil; analysis of harmful metals in paints, paints, pigments, and plastics.

- Metal identification, scrap metal classification.

- Petrochemical industry, catalyst, and additive element analysis.

- QC/QA in metal production, casting, etc.

- Pharmaceutical Biomedicine.

- Geological and mineral fields: mines, ore analysis, mineral analysis, beneficiation process control.

- Material field: Component analysis and quality control of refractory materials, glass, ceramics, cement, etc.

Different Applications of Spectrophotometer

| Application | Spectrophotometer Type | Picture | Model |

| Gold in Ore, Metallurgy. Geology, Mining, Petroleum. Cement, Soil, Medicine, etc. |

AAS |  |

DW-AA320N |

| Alloy, Mineral, Precious Metal, RoHS, Catalyst etc. | XRF |  |

DW-NP-5010 |

|

EDX3600H | ||

|

TrueX 900 | ||

|

EDX800 | ||

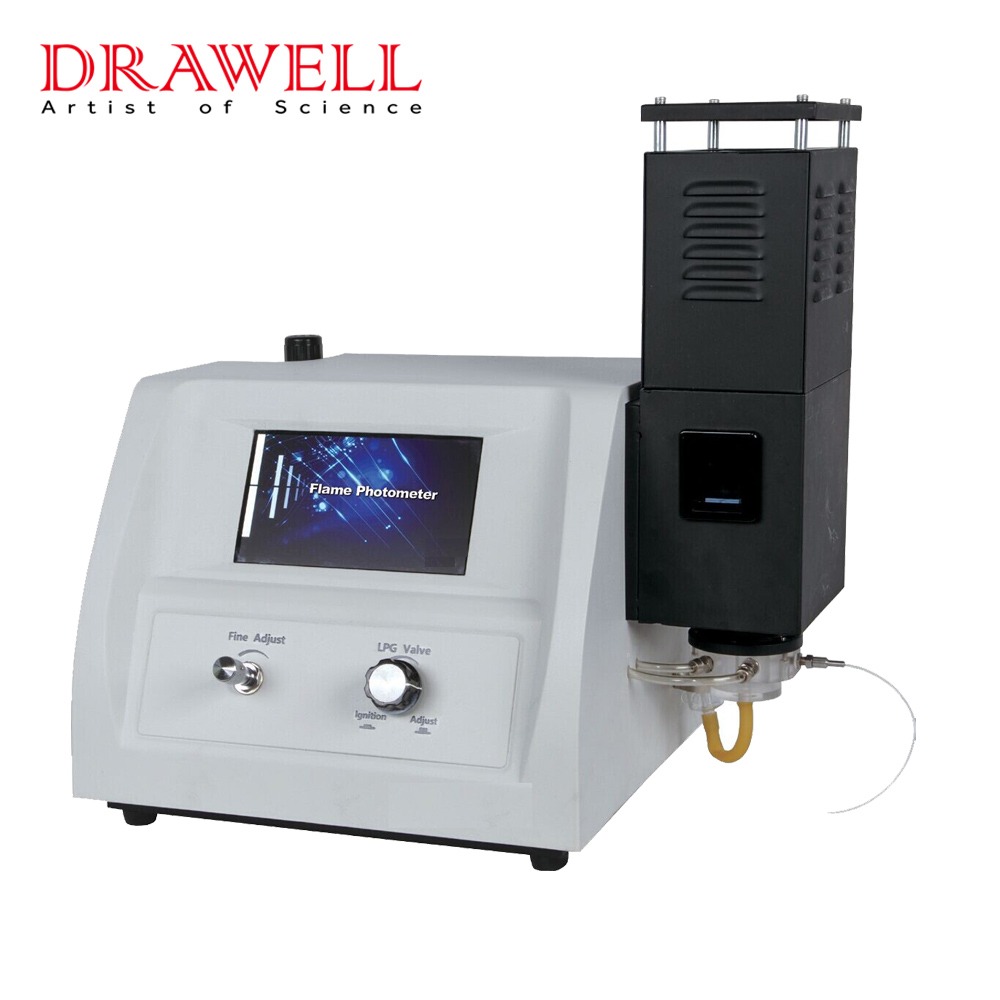

| MaterialsAnalysis, Geology, Petrochemicals, Biology, Cement, Soil, Cosmetics, Food, etc. |

ICP-AES |  |

DW-TY-9900 |

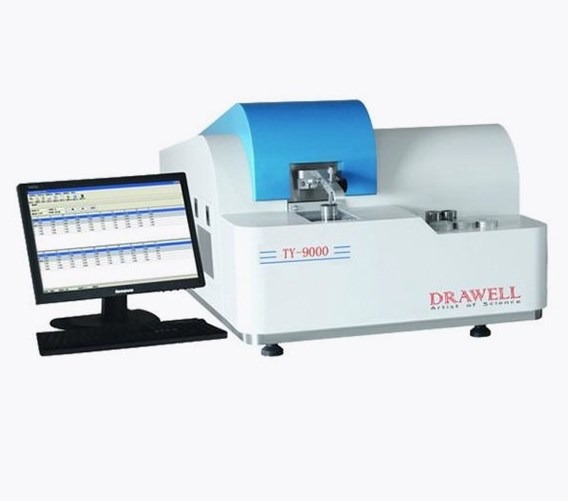

| Foundry, Steel, Metal Recovery, Smelting, MilitaryAerospace, etc. | Full Spectrum Direct Reading Spectrometer |  |

DW-TY9000 |

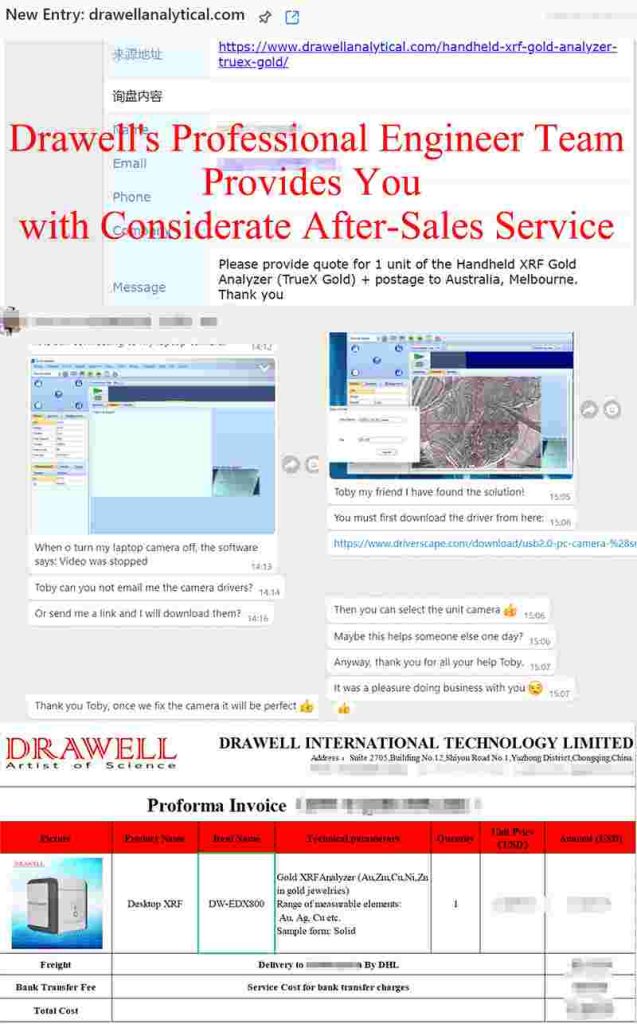

Why Choose Us for XRF?

– Free Training for Customers

Free training in user’s location about installation, debug test, training, and technical services.

We provide 1-year warranty against normal daily use problems or material defects, but the term is there is no other person disassembling action besides our own engineers.

– Lifelong Maintenance

– Provide Free Software Upgrades

Provide the most effective technical services, and respond to customers within 24 hours.

Customer Feedbacks: