Sterilization is a critical aspect of various industries, from healthcare to research laboratories, necessitating advanced and efficient solutions. Among the cutting-edge technologies transforming sterilization processes, fully automatic vertical autoclaves have emerged as pioneers in ensuring not just effectiveness but also streamlined operation. This article delves into the innovative world of fully automatic vertical autoclaves, exploring their features, applications, and the transformative impact they bring to sterilization practices.

Understanding the Basics

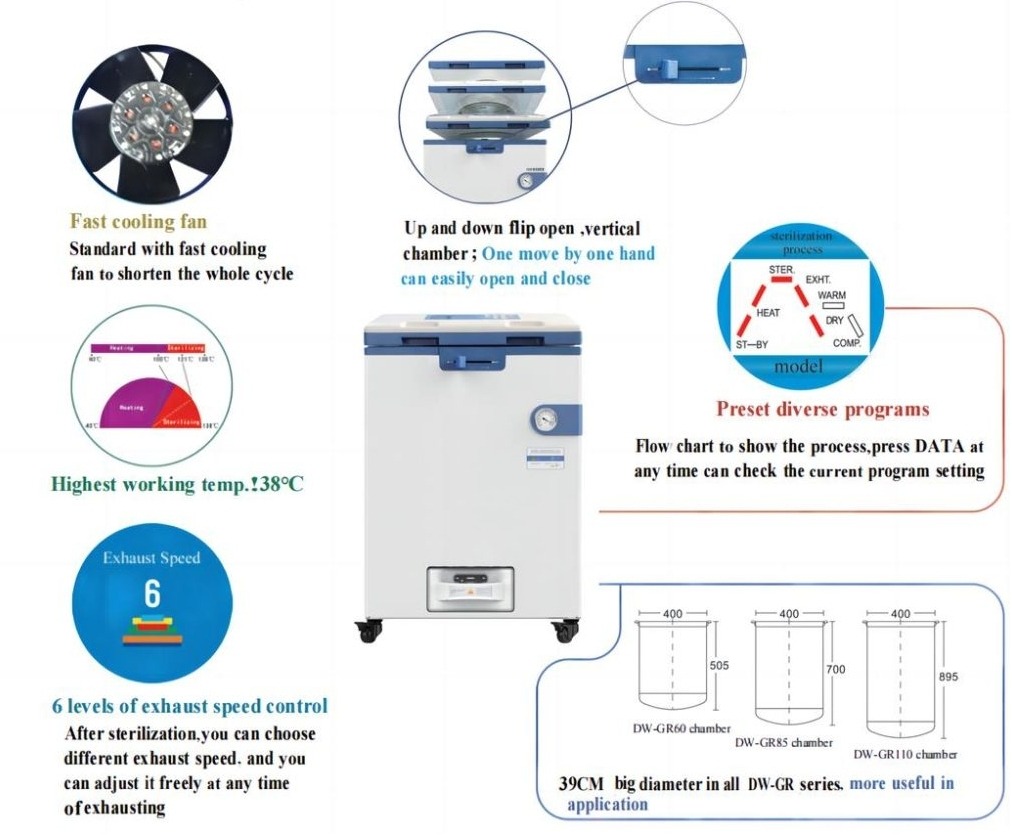

Fully automatic vertical autoclaves are sophisticated sterilization devices designed to simplify and enhance the autoclaving process. These autoclaves are vertically oriented, allowing for efficient use of space and providing a practical solution for facilities with spatial constraints. Unlike traditional autoclaves that require manual intervention, fully automatic vertical autoclaves operate seamlessly, automating the entire sterilization cycle.

How does Fully Automatic Vertical Autoclave Work?

The sterilization process within a fully automatic vertical autoclave is initiated by loading the items to be sterilized into the chamber and sealing the door securely. The autoclave’s control system then takes charge, automatically initiating a series of steps:

- Air Removal: The autoclave removes air from the chamber using a vacuum pump, creating an environment devoid of oxygen, which is essential for effective steam sterilization.

- Steam Injection: Steam is introduced into the chamber at a predetermined pressure, typically around 15 psi (1.03 bar). The steam, reaching temperatures of around 121°C (250°F), permeates the chamber, enveloping the items and denaturing the proteins of microorganisms, rendering them inactive and harmless.

- Sterilization Cycle: The sterilization cycle maintains the high-pressure steam environment for a specified duration, typically 15-30 minutes, ensuring complete sterilization of the items.

- Exhaust and Drying: Once the sterilization cycle is complete, the steam is gradually exhausted from the chamber, and a drying cycle may be initiated to remove residual moisture from the sterilized items.

Features that Define Excellence

The adoption of fully automatic vertical autoclaves has transformed sterilization practices, offering a multitude of advantages:

Enhanced Efficiency: Automated operation streamlines sterilization procedures, minimizing human error and maximizing productivity. Comprehensive data logging capabilities enable the recording and storage of sterilization parameters. This not only facilitates compliance with regulatory requirements but also assists in quality control and process optimization.

Improved Safety: Automated safety features, such as pressure interlocks and temperature sensors, safeguard against operational mishaps.

Consistent Sterilization: Precise control over temperature, pressure, and cycle duration ensures consistent and reliable sterilization outcomes. These autoclaves come equipped with state-of-the-art control systems that regulate temperature, pressure, and cycle times with unparalleled accuracy. The result is a consistently reliable sterilization outcome, meeting the highest industry standards.

User-Friendliness: Intuitive control panels and straightforward operation make these autoclaves accessible to users with varying levels of technical expertise.

Applications Across Industries

- Healthcare

In medical facilities, fully automatic vertical autoclaves play a crucial role in ensuring the sterility of surgical instruments, medical devices, and laboratory equipment. The automation of these processes minimizes the risk of human error and enhances the overall safety of patients and healthcare professionals.

- Research and Laboratories

Research laboratories benefit from the precision and reliability offered by fully automatic vertical autoclaves in sterilizing glassware, media, and other critical materials. The automated features contribute to workflow efficiency, allowing scientists to focus on their research without compromising on sterility.

- Pharmaceutical Manufacturing

Pharmaceutical companies rely on fully automatic vertical autoclaves to sterilize components used in drug manufacturing, ensuring the integrity of the final products. The automation of the sterilization process contributes to a more streamlined and compliant manufacturing environment.

Conclusion

Fully automatic vertical autoclaves represent a paradigm shift in sterilization technology, offering a combination of automation, efficiency, and safety that has revolutionized sterilization practices across diverse industries. These innovative devices play a crucial role in safeguarding public health, ensuring the sterility of medical supplies, and maintaining the integrity of products in various manufacturing processes. As technology advances, fully automatic vertical autoclaves are poised to continue evolving, incorporating even more sophisticated features and capabilities, further enhancing their effectiveness and versatility in the realm of sterilization.