Autoclaves rely on pressurised steam to eliminate pathogens from surgical tools, glassware, culture media, and many other items crucial to sectors such as hospitals, laboratories, research facilities, and pharmaceutical manufacturing. Within that broad category, horizontal and vertical models are the most widely used, each tailored to specific workflows and space constraints. Understanding how these two designs differ is key to selecting the unit that will best serve your operational needs.

What are Vertical Autoclaves

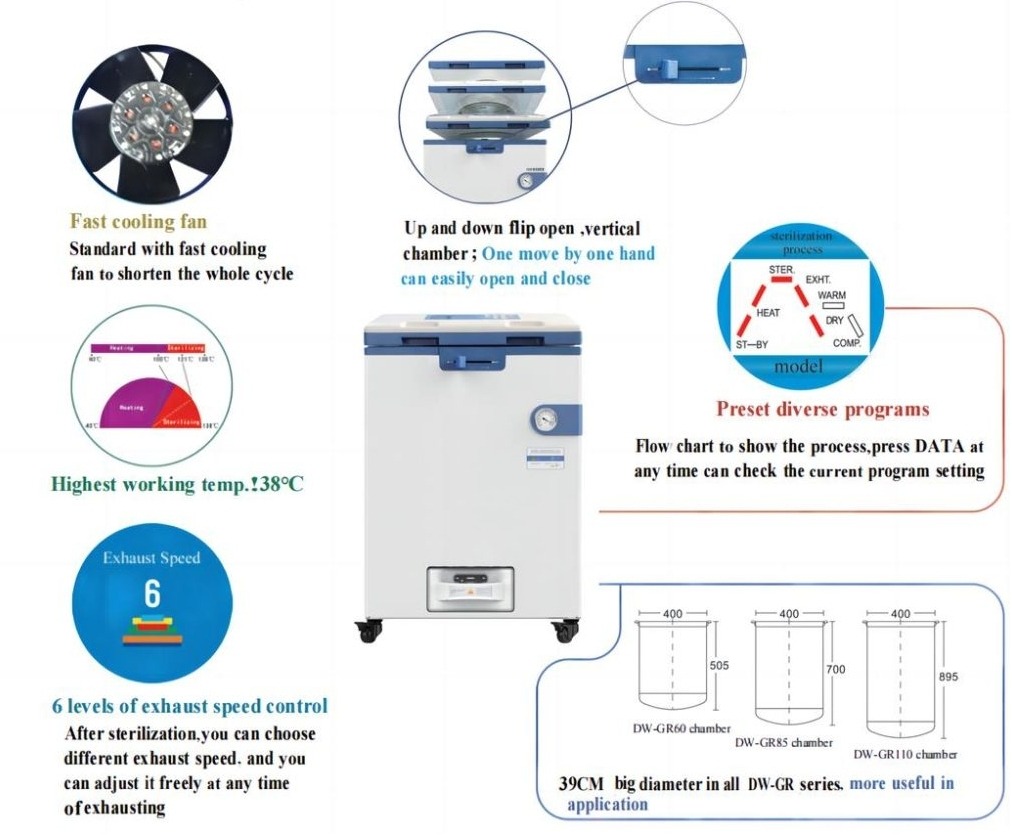

Vertical autoclaves, sometimes called upright steam sterilizers, feature a top-loading cylindrical chamber favoured by medical labs, small clinics, and research groups. They efficiently process glass vials, surgical instruments, culture plates, and other heat-stable payloads using high-pressure steam that circulates quickly around each item. Compact, cost-effective, and easy to tuck into limited floor space, vertical units suit facilities with moderate sterilisation volumes and a need for rapid turnaround.

Working Principle

Vertical autoclaves are based using an idea of moisture heat sterilization, which uses pressure-saturated steam that kills every form of microbial life, which includes the spores. The process generally takes place in the following steps:

- Loading: Items for sterilization are placed in the vertical chamber starting from the top. Trays and baskets are typically used to stack items.

- Heating & Steam Generation: The chamber’s water (or an integral reservoir) gets heated up, producing steam.

- Pressurization: After the chamber has reached the temperature set (typically 121degC-134degC) then the pressure starts to build upwards (usually around 15-30psi) to ensure that the steam is completely saturated.

- Sterilization: It is subjected this steam at high pressure for a certain amount of time typically 15-30 minutes, according to the type of load.

- Depressurization & Drying: Following the sterilization process after the sterilization process, pressure is let go gradually. Certain vertical autoclaves that are more advanced offer partial drying, however full drying is more prevalent for horizontal models.

- Unloading: After cooling after cooling, the sterilized substances are taken away.

This method ensures the efficient removal of all viruses, bacteria as well as fungi and spores from the materials inside.

Advantages

Vertical autoclaves provide a variety of advantages, especially for small- to medium-sized environments:

- Space-Saving Design: Their upright and compact design of vertical autoclaves makes them ideal for laboratories with a limited available floor space.

- Cost-Effective: The cost is generally lower than horizontal autoclaves, with regard to initial cost as well as maintenance.

- Simplicity: It is easy to install as well as operate with little instruction needed.

- Energy Efficient: Smaller chambers use less water and energy to finish a sterilization process.

- Ideal for Batch Sterilization: It is suitable for sterilizing small quantities of glassware, tools, or even culture media.

Limitations

While they offer many benefits they also come with a few drawbacks:

- Limited Capacity: The chamber’s size limits the quantity of substances to be sterilized in the same time.

- Top-Loading Ergonomics: Users have to move items up and down the chamber. This is physically demanding, particularly when dealing with heavy or hot objects.

- Manual Drying: A lot of instruments lack advanced drying features, which requires external drying after sterilization.

- Not Suitable for Large-Scale Use: In high-throughput settings, vertical autoclaves aren’t able to keep up with demand.

- Slower Workflow Integration: They aren’t easy to integrate into automated cleanroom workflows or sterilization lines.

What are Horizontal Autoclaves

Horizontal autoclaves come with a front-loading design and a rectangular chamber tailored for medium- and large-volume applications. Found in hospitals, biomedical labs, and food-processing plants, they offer greater load capacity, ergonomic handling, and automation-ready options. This layout allows staff to slide in carts or trays of bulky materials with minimal bending, making the units well-suited for facilities that sterilise large batches on a routine basis.

Working Principle

Horizontal autoclaves work on the principle of moist heat sterilization in which saturated pressurized steam is used to kill microorganisms such as bacteria and viruses, fungi and spores. The sterilization process generally comprises these steps.

- Loading: The items to be sterilized are laid out on trolleys or trays and then inserted into the front loading rectangular chamber.

- Air Removal: Prior to the introduction of steam the chamber goes through an air gravitation displacement or vacuum cycle in order to remove air. Vacuum-assisted models are more efficient in air removal and allow for greater steam penetration.

- Steam Injection & Heating: The steam is infused with saturated steam into the chamber, quickly increasing temperatures to 121-134 degrees Celsius, dependent on the type of load.

- Sterilization Holding Phase: The chamber is maintained at the pressure and temperature set (typically between 15-30 PSI) for a specified time (usually fifteen to thirty minutes) to ensure complete sterilization.

- Exhaust & Drying: Following the sterilization stage steam is released and the chamber is subjected to an air drying process by through heat or vacuum.

- Cooling & Unloading: When pressure is normalized and temperatures drop The door can be safely opened and the sterilized items are taken out.

This method ensures dependable and consistent sterilization even in the case of complex or heavy loads. This process ensures uniform and reliable sterilization even for complex or dense.

Advantages

Horizontal autoclaves have a wide array of benefits which make them suitable for use in high volume:

- Large Capacity: Their large, spacious chambers permit the sterilization of large quantities such as surgical instrument packs glassware, textiles, and biohazardous waste.

- Enhanced Ergonomics: The front loading design and carts or trays reduce physical strain and allow for the easy handling of large or bulky objects.

- Superior Air Removal: Vacuum-assisted models ensure complete air elimination, improving sterilization efficiency–especially for porous or wrapped items.

- Advanced Automation: Many autoclaves that are horizontal come with programable controls, data logs remote monitoring, and automated drying, which supports GMP conformity and process standardization.

- High Throughput: Perfect for use continuously in busy areas such as theaters for operating and pharmaceutical production lines or research institutes.

Limitations

Despite their excellent abilities, horizontal autoclaves are abound with some limitations:

- Higher Initial Cost: These autoclaves are substantially more expensive than horizontal or tabletop models in terms of cost and upkeep.

- Larger Footprint: They require more space for floor and is not always feasible in smaller clinics or laboratories.

- Complex Installation: Horizontal autoclaves could require separate plumbing as well as the use of steam generators for drainage as well as electrical connection.

- Greater Maintenance Needs: With more components and sophisticated automation, they usually require periodic calibration and servicing.

- Not Ideal for Small Loads: The operation of an autoclave that is large for a small amount of food is inefficient with regard to energy and time.

Key Differences Between Vertical and Horizontal Autoclaves

| Feature | Vertical Autoclave | Horizontal Autoclave |

| Design Orientation | Top-loading cylindrical chamber | Front-loading, rectangular chamber |

| Loading Method | Manual loading at the top | Cart loading or sliding tray from the front |

| Space Requirement | Compact footprint, suited for smaller space | Needs more area for floor |

| Capacity | Ideal for medium-sized to small loads | The system is suited for medium-sized to large size sterilization |

| Ease of Loading/Unloading | More ergonomic; requires lifting objects in and out | A more ergonomic design; easier handling using trays/trolleys |

| Cycle Control | Basic controls, usually manual | Advanced control programmable with automation |

| Drying Capability | Drying is not as easy or requires manual effort. | Drying systems that are integrated and efficient. |

| Cost | Lower initial and maintenance costs | Costs are higher due to the larger dimension and sophisticated features |

| Air Removal Efficiency | Typically, gravity displacement | Often, vacuum pumps are included to ensure efficient air removal |

| Suitable for Automation | Not usually designed to be integrated | Integrates to automatized sterilization processes |

Key Factors to Consider for Choosing Between Vertical and Horizontal Autoclaves

The decision between horizontal and vertical autoclaves is based on the mixture of your facilities requirements for workflow and space availability and sterilization volumes, as well as longer-term operational objectives.

- Space and Installation Requirements

One of the primary aspects to consider when deciding between horizontal and vertical autoclaves is how much space you have within your facility. Vertical autoclaves are small and top-loading. They are ideal for smaller laboratories or clinics where floor space is an all-time low. They can be set up in tight corners without making major modifications to the workspace. However horizontal autoclaves need greater space due to their front-loading designs with a rectangular chamber. They usually require special utility connections, which include drainage lines, steam lines as well as electrical and drainage systems which makes them ideal for establishments equipped with the infrastructure to provide them with support.

- Load Size and Frequency of Use

The frequency and volume of sterilization procedures are crucial aspects that affect the selection. Vertical autoclaves work best for moderate to light sterilization processes and are typically employed in areas with less frequent or batch-based sterilization demands. They are great to sterilize smaller items such as laboratory glassware, instruments and culture medium. Contrary to this horizontal autoclaves are designed to be used in heavy-duty, continuous usage. The larger capacity of their chambers can handle heavy items big batches, as well as continuous cycles, which is ideal for pharmaceutical facilities, hospitals and industrial laboratories.

- Ergonomics and User Convenience

User handling and ergonomics vary dramatically between the two kinds. Vertical autoclaves require manual top loading that may require lifting and lowering large or hot substances. This could be physically demanding and could increase the chance of accidents. Horizontal autoclaves are much easier to unload and load and often have wheels or sliding trays which reduce physical strain and enhance efficiency in workflow. They are also more user-friendly in high-throughput settings where security and comfort are top priorities.

- Control Systems and Sterilization Precision

Control capabilities are another area that sets them apart. Vertical autoclaves are typically equipped with more basic, often manual control systems that are suitable for simple sterilization cycles. Although they can meet the general laboratory standards, they might not provide the accuracy or flexibility required in industries that are regulated. Horizontal autoclaves typically have advanced PLCs that can be programmed (PLCs) with multi-cycle capabilities and monitoring in real-time. These options allow for precise cycle configuration, consistent results, and are in compliance with standards like GMP as well as ISO.

- Drying Performance and Air Removal

Effective sterilization is often dependent on a high efficiency in drying and removal of air. Horizontal autoclaves typically have vacuum-assisted air removal systems as well as integrated drying capabilities that improve sterilization efficiency, especially for pliable loads or instruments packed with surgical fluids. A lot of vertical autoclaves, especially simple models, depend on gravity displacement, and might not have built-in drying. This may need additional procedures or equipment following sterilization.

- Cost and Investment Considerations

Budgetary constraints play an important influence on the final decision. Vertical autoclaves tend to be less expensive with regards to initial purchase and maintenance, which makes them suitable for small-scale businesses or for facilities that have limited resources. Horizontal autoclaves require a greater initial investment, but they provide long-term benefits in terms of efficiency, automation and lower labor costs. Facilities that have high throughput as well as strict standards for compliance may appreciate the extra investment.

- Application Suitability

The final decision must coincide with the specific use and requirements of the industry. For everyday lab usage and academic settings or small clinics, the vertical autoclave is typically adequate and a practical. However industries that need approved sterilization procedures for example biotechnology, pharmaceuticals, or hospitals of a large size will gain more from the strength and adherence capabilities of an autoclave that is horizontal.

For smaller spaces and laboratories that are budget-conscious, vertical autoclaves provide a space-efficient and cost-effective option.

Horizontal autoclaves offer higher capacity, more automation options and ergonomic advantages for industrial sterilization or large-scale requirements.

Final Thoughts

The selection of vertical and horizontal autoclaves must be based on the specific requirements of the sterilization process. Knowing these distinctions will ensure that your establishment invests in the best sterilization technique, increasing effectiveness, safety, and conformity to hygiene standards.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.