With consumers increasingly concerned about the quality, freshness, and safety of the products they consume, food manufacturers are constantly seeking innovative solutions to meet these demands. One such technology that has gained prominence in recent years is the High Pressure Homogenizer. This article explores the principles of high pressure homogenization and its role in in enhancing food safety, improving product quality, and extending shelf life.

Understanding High Pressure Homogenization

High Pressure Homogenization (HPH) is a process used to achieve particle size reduction, emulsification, and dispersion of materials, widely applied in various industries including food, pharmaceuticals, cosmetics, and biotechnology. It involves subjecting a substance to extremely high pressures, typically ranging from 100 to 2000 bar (1 to 20 kbar), to create intense shear forces and turbulence within the material. This process is conducted using specialized equipment called High Pressure Homogenizers.

Key Components and Processes Involved in High Pressure Homogenization

1. High Pressure Pump

The process begins with a high-pressure pump that generates the necessary pressure to drive the product through the homogenization chamber. These pumps are specifically designed to handle the high pressures required for homogenization.

2. Homogenization Chamber

The homogenization chamber is where the product undergoes the high-pressure treatment. It typically consists of a narrow annular orifice through which the product passes. The size of the orifice can be adjusted to control the intensity of the homogenization process.

3. Product Inlet

The product to be homogenized is fed into the homogenization chamber through a product inlet. Depending on the application, the product may be preheated or cooled to optimize the homogenization process.

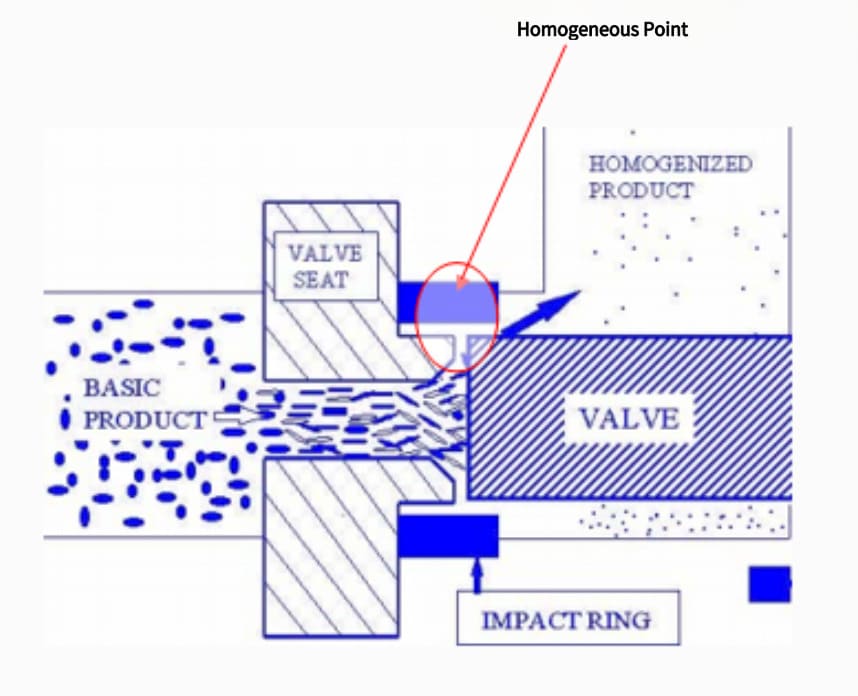

4. High Pressure Valve

At the heart of the homogenization process is the high-pressure valve, which is responsible for generating the high pressure required to force the product through the narrow gap. The valve rapidly opens and closes, creating a pressure drop across the orifice and inducing intense shear forces and turbulence in the product.

5. Homogenization Effect

As the product passes through the narrow gap at high pressure, it undergoes intense shear forces, cavitation, and turbulence. This results in the breakup of particles, droplets, or cells present in the product, leading to particle size reduction, emulsification, dispersion, and mixing. The high pressure also contributes to the inactivation of microorganisms, thus extending the shelf life of food products.

6. Product Outlet

After passing through the homogenization chamber, the homogenized product exits through a product outlet. Depending on the application, the product may undergo further processing steps such as cooling, packaging, or additional treatments.

Key Applications of High Pressure Homogenizers for Ensuring Food Safety

1. Microbial Control and Pathogen Reduction

High pressure homogenization is effective in reducing microbial contamination and pathogens in food products. The high-pressure forces exerted during homogenization disrupt the cellular structures of microorganisms, including bacteria, viruses, and fungi, rendering them inactive or destroying them entirely. This process helps to minimize the risk of foodborne illnesses caused by pathogens such as Salmonella, Escherichia coli (E. coli), and Listeria monocytogenes.

2. Sterilization of Ingredients

Ingredients used in food production, such as milk, juices, and sauces, can be sterilized using high pressure homogenizers. By subjecting these ingredients to high pressure and shear forces, homogenization effectively eliminates microbial contaminants, ensuring the safety and quality of the final product. This is particularly important for ingredients that may contain harmful microorganisms and could pose a risk to consumer health if not properly treated.

3. Extended Shelf Life

High pressure homogenization helps to extend the shelf life of food products by reducing microbial load and inhibiting spoilage. By disrupting the cellular integrity of microorganisms and enzymes responsible for food deterioration, homogenization slows down the rate of spoilage and extends the freshness and quality of perishable food items. This is especially beneficial for products with a limited shelf life, such as dairy products, beverages, and liquid food formulations.

4. Uniform Dispersion of Additives and Preservatives

High pressure homogenizers ensure the uniform dispersion of additives, preservatives, and other functional ingredients in food products. By subjecting the product to intense shear forces and pressure gradients, homogenization disperses these ingredients evenly throughout the product matrix, ensuring uniformity of flavor, texture, and functional properties. This helps to enhance product quality and consistency while ensuring that preservatives are distributed effectively to inhibit microbial growth and prolong shelf life.

4. Creation of Stable Emulsions and Suspensions

High pressure homogenization is widely used to create stable emulsions and suspensions in food products. By reducing particle size and achieving uniform dispersion of immiscible phases, homogenization helps to create stable emulsions of oil and water, as well as suspensions of solid particles in liquid matrices. This is essential for the production of products such as mayonnaise, salad dressings, sauces, and dairy products, where stability and uniformity are critical for both safety and consumer acceptance.

Conclusion

High pressure homogenization is a versatile and effective technology for enhancing food safety standards in the food industry by reducing microbial contamination, extending shelf life, and improving product quality and consistency. With their versatile applications and proven effectiveness, high pressure homogenizers continue to be indispensable tools in the food industry’s efforts to deliver safe, high-quality food products to consumers worldwide.