The introduction of the laboratory freeze dryer

The laboratory freeze dryer is manufactured by the principle of vacuum drying. The principle of the instrument is to first freeze the water-containing material into a solid state and then sublime the water in it from the solid state to the gaseous state, thereby removing the water and preserving the material. It has a compact and reasonable structure, convenient maintenance, automatic control, and easy operation. Under the same material heating temperature, it has a faster drying speed( (the time is shortened by 3 ~10 times) than conventional vacuum drying and ovens. Besides, it is 2~3 times lower energy consumption than theirs. The drying temperature range is wide and can be dried at 0°C~120°. It is fast drying in a low-temperature range from 0°C to 50°C. The drying chamber is an oxygen-free vacuum. The drying quality can be comparable to the quality of freeze-dried materials. It can recycle organic solvents, which is conducive to reducing production costs and environmental protection. Besides, it is especially suitable for materials containing organic solvents that cannot be dried in general.

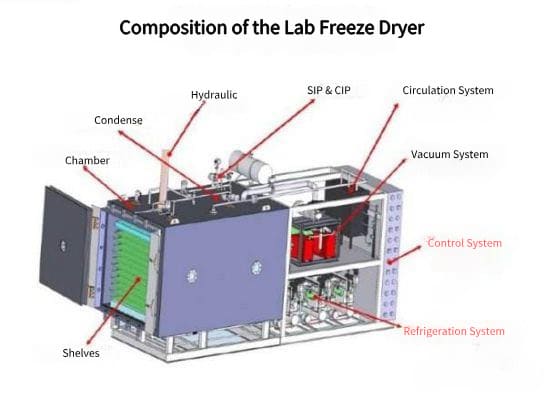

The composition of the lab freeze dryer

Laboratory freeze dryer equipment is a small freeze dryer used for the freeze drying of a small number of samples in the laboratory, including a shell, a refrigeration unit, a vacuum pump, a cold trap, and an electric control system. It is a commonly used type of dryer product, mainly composed of a refrigeration system, vacuum system, heating system, and electrical instrument control system. The product has the advantages of stable performance, safe and reliable use, and easy maintenance.

The refrigeration unit is arranged in the casing. The cold trap is arranged on the upper part of the casing. The vacuum pump is connected to the cold trap through a vacuum pipeline. The refrigeration unit has a compressor, a heat exchanger, an expansion valve, and an evaporator. The material placement device is installed above the cold trap and on the shell, and communicated with the upper end of the cold trap. The evaporator is an evaporation coil, which is arranged in the cold trap. The evaporator is changed to an evaporative coil. It is set in a cold trap. The cooling speed is fast.

How to use a laboratory freeze dryer?

1. Take the pre-freezing rack out of the cold trap.

2. Take out the pre-frozen materials and put them on the drying rack.

3. Put the drying rack on top of the cold trap.

4. Cover the “plexiglass cover” under the premise of checking that the sealing ring is intact and free of debris.

5. Tighten the drain valve clockwise.

6. Turn on the vacuum pump and turn on the vacuum gauge. The vacuum degree decreases, and the vacuum degree value is less than 20pa during the drying process, which is normal.

7. Hang the flasks one by one and open the multi-manifold valve. After the contents in the flask are dried, you should close the multi-manifold valve and remove the flask.

8. After drying, first open the water intake valve. And then close the vacuum pump. If you need to press the vial, turn the capping handle clockwise, press the stopper well, and then release the air. Remove the plexiglass cover and collect the dry matter.

9. Turn off the power supply, close the water inlet and valve, and defrost the equipment. After defrosting, open the water inlet and valve to drain, and wipe the equipment clean.

10. When the vacuum pump is not working, please cover the exhaust hole to prevent dust from entering.

According to the above introduction of the Laboratory freeze dryer manufacturer, this product is widely used in laboratory scientific research and technical fields such as biopharmaceutical, chemical, and food. If you want to know more about this product, the best method is to consult the lab freeze dryer manufacturer which can give more comprehensive information and advice on choosing a lab freeze dryer.

Related Products Recommendation