Atomic Absorption Spectrophotometry (AAS) is a powerful analytical technique widely used for the determination of metal concentrations in various samples. With its exceptional sensitivity and selectivity, AAS enables the accurate quantification of specific elements in complex matrices. By leveraging the principles of light absorption and atomic transitions, AAS has become an invaluable tool in fields such as environmental monitoring, metallurgy, mining, and quality control. In this article, we provide an overview of the types of Atomic Absorption Spectrophotometers (AAS) and explore their applications within the realm of metal analysis. Hope these information can help you select the most suitable instrument for your analytical needs.

What Are the Types of Atomic Absorption Spectrophotometer (AAS)?

There are several types of atomic absorption spectrophotometers (AAS) based on their design and features. The main types include:

- Single-Beam Atomic Absorption Spectrophotometer: This is the most basic type of AAS, where the instrument measures the absorbance of the sample by comparing it to a reference blank. It uses a single light beam that alternately passes through the sample and the reference solution.

- Double-Beam Atomic Absorption Spectrophotometers: In this type, the instrument splits the light beam into two paths, one passing through the sample and the other through a reference solution simultaneously. The absorbance of the sample is then determined by comparing the two beams. Double-beam AAS compensates for drifts in the light source or other optical components, providing improved stability and accuracy.

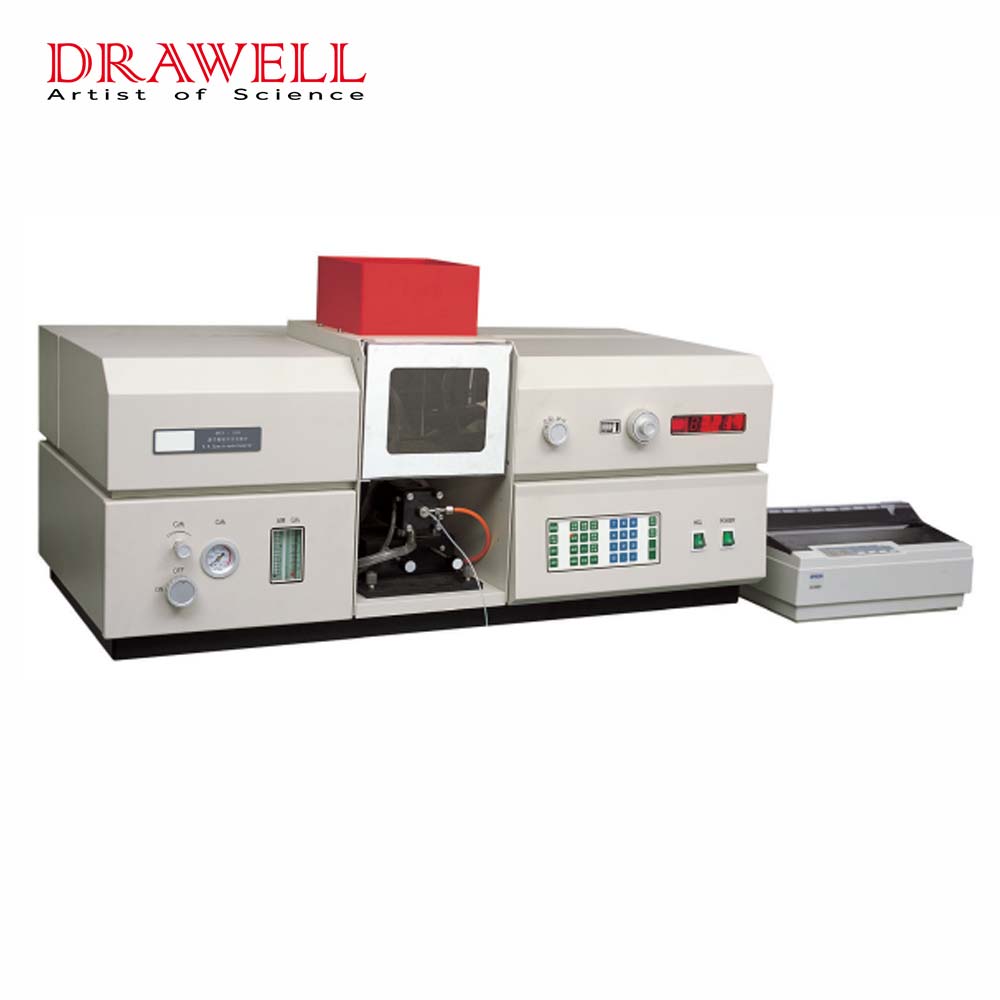

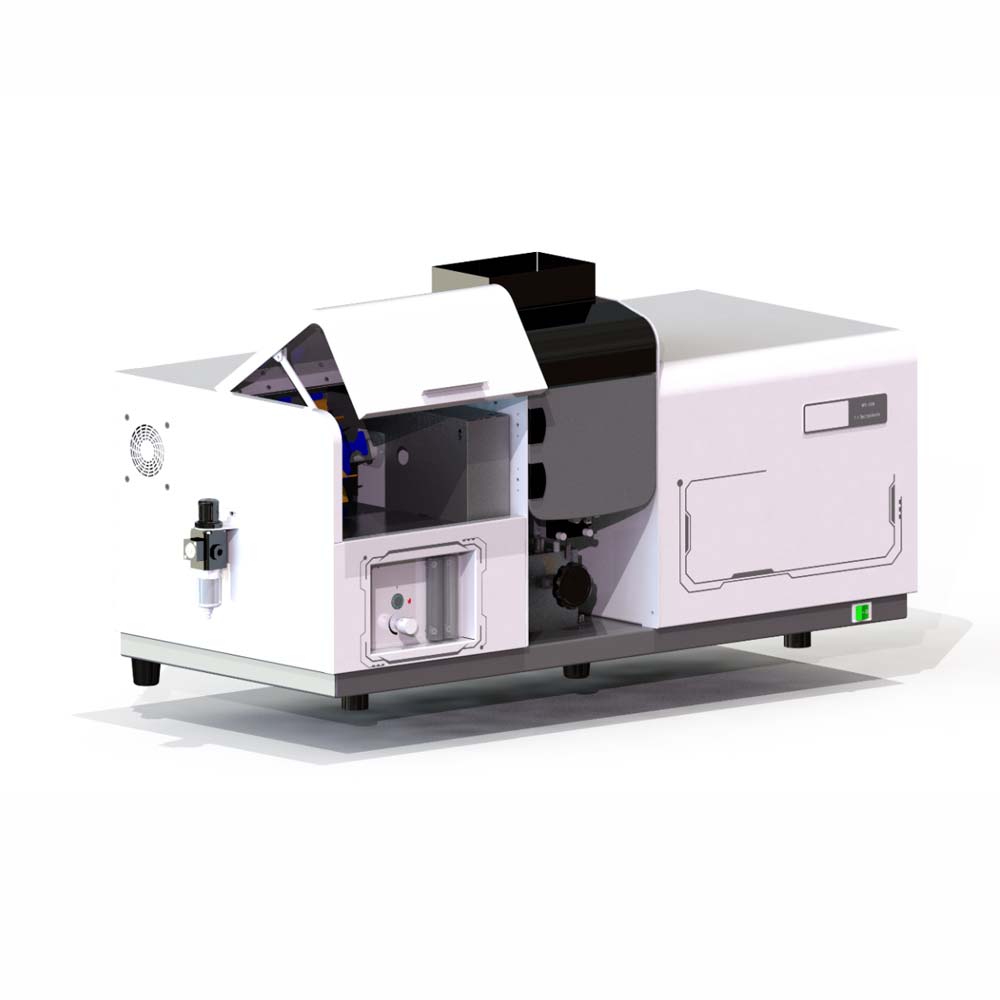

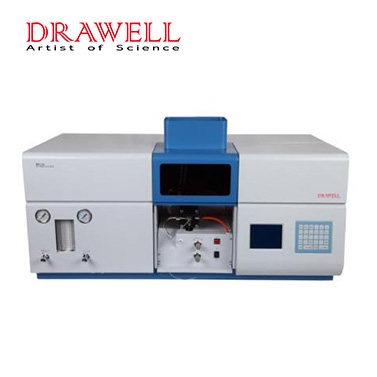

- Flame Atomic Absorption Spectrophotometers: Flame AAS instruments are designed specifically for analyzing samples in a flame atomization system. They utilize a nebulizer to introduce the liquid sample into the flame and measure the absorption of light by the atoms in the vapor phase.

- Graphite Furnace Atomic Absorption Spectrophotometers: Graphite furnace AAS (GFAAS) instruments are used for analyzing small sample volumes and trace elements. They employ a graphite furnace as the atomization and measurement cell. The sample is introduced into the graphite tube, and the temperature is ramped up to vaporize and atomize the sample for analysis.

- Hydride Generation Atomic Absorption Spectrophotometers: Hydride generation AAS instruments are used for the determination of elements that can form volatile hydrides. They involve the generation of volatile hydride species from the sample, which are then introduced into the atomization system and measured for absorption.

These different types of AAS instruments are designed to suit specific applications and analytical requirements. The choice of the appropriate AAS type depends on factors such as the target elements, required detection limits, sample matrix, and specific analysis needs.

What Are the Applications of Atomic Absorption Spectrophotometer(AAS) in Metal Analysis?

Atomic absorption spectrophotometers (AAS) are commonly used in the analysis of metals due to their ability to measure the concentration of specific elements accurately. Here is how atomic absorption spectroscopy is used for the analysis of metals:

- Sample Preparation: The first step involves preparing the metal sample for analysis. This may include dissolving the metal in an appropriate acid or solvent to create a solution that can be introduced into the AAS instrument. The sample may also undergo further treatment or filtration to remove any interfering substances.

- Atomization: In AAS, the sample is atomized to convert the metal atoms into a gaseous state. Depending on the type of AAS being used, atomization can be achieved through flame atomization or graphite furnace atomization. Flame AAS uses a nebulizer to introduce the liquid sample into a flame, where the metal atoms are vaporized. Graphite furnace AAS, on the other hand, uses a graphite tube to heat and vaporize the sample.

- Light Source: AAS utilizes a specific wavelength of light that is absorbed by the metal atoms of interest. The instrument incorporates a light source that emits this wavelength, typically generated by a hollow cathode lamp specific to the element being analyzed. The emitted light passes through the atomized sample.

- Absorption Measurement: The AAS instrument includes a monochromator or filters that select the desired wavelength of light for analysis. The light that passes through the atomized sample is measured by a detector, which quantifies the intensity of the transmitted light.

- Calibration and Analysis: A calibration curve is established by analyzing standard solutions with known concentrations of the metal of interest. The relationship between the absorbance and the concentration of the standard solutions is used to determine the concentration of the metal in the sample. The absorbance of the sample is measured, and its concentration is determined by comparing it to the calibration curve.

- Data Analysis: The AAS instrument provides a measurement of the absorbance, which is then used to calculate the concentration of the metal in the sample. The results are typically expressed in units such as parts per million (ppm) or milligrams per liter (mg/L) depending on the specific analysis requirements.

By utilizing AAS, analysts can accurately determine the concentration of metals in various samples. This has applications in industries such as environmental monitoring, metal production, quality control, and research where precise knowledge of metal concentrations is essential.

Atomic Absorption Spectrophotometry (AAS) plays a pivotal role in the analysis of metals by offering accurate and reliable quantitative measurements of metal concentrations. The various types of AAS instruments, including FAAS, GFAAS, and HGAAS, provide diverse capabilities for metal analysis. Their applications span across environmental monitoring, metallurgy, mining, and quality control, ensuring the integrity, safety, and compliance of metals used in various industries. Understanding the capabilities and applications of AAS instruments empowers researchers and analysts to make informed decisions in their pursuit of precise metal analysis.