For the processing of materials, especially in the food, pharmaceutical cosmetics, nanotechnology, and food industries, the necessity for a fast and efficient homogenization process of emulsions and particles resulted in the development of a variety of techniques. The most popular methods are ultrasonic homogenizers and high-pressure homogenizers. Each has its own advantages and drawbacks, making the decision based on needs of the application. This article will discuss the basic working principles of advantages, disadvantages, and the application areas of ultrasonic vs. high pressure homogenizer and the best way to select which one is best for you between the two methods.

What is an Ultrasonic Homogenizer

Ultrasonic homogenizers are now essential instruments in laboratories for research and industrial applications where precise dispersion, emulsification, and cell dispersion are essential. This technology utilizes high-frequency sound waves to transfer mechanical energy to liquids which is particularly efficient in fields such as food technology, pharmaceuticals nanomaterials, and biotechnology.

How Does a Ultrasonic Homogenizer Work

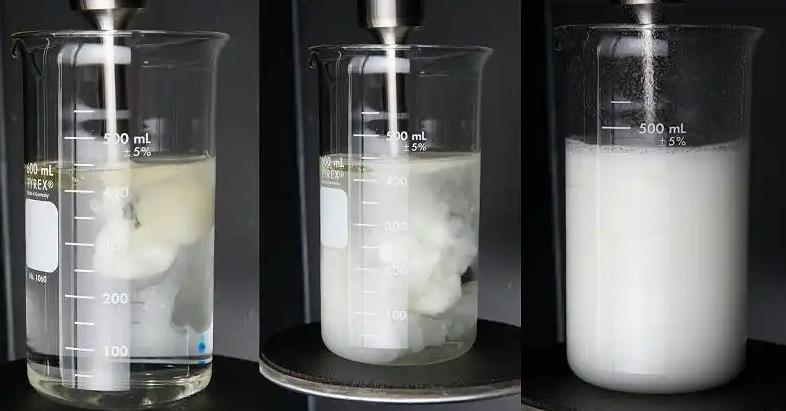

The core principle of the ultrasonic homogenizer lies the transducer, which transforms electrical energy into high-frequency ultrasonic waves, which typically range from 20 kHz up to 40 kHz. The vibrations are transmitted by probes (also called the sonotrode or horn) directly into the liquid medium. As the ultrasonic waves pass across the fluid, they trigger the cycles of rarefaction and compression which result in the creation micro-sized bubbles.

This process, also known as Acoustic Cavitation, causes these bubbles to collapse rapidly and release intense localized energy through shock waves and high shear forces and even transient high temperatures. These forces are strong enough to rupture cell membranes, disintegrate particle fragments, as well as mix impermeable materials into solid emulsions and suspensions.

Key Applications of Ultrasonic Homogenizers

- Biotechnology: Cell lysis is used to extract DNA proteins, RNA or DNA.

- Pharmaceuticals: Preparation of nanoemulsions as well as delivery systems for drugs.

- Food Industry: Homogenizing sauces dairy products, sauces, and drinks to enhance texture and shelf-life.

- Cosmetics: Dispersion of ingredients and pigments in lotions and creams.

- Nanotechnology: Disaggregation and stabilization of nanoparticles.

Advantages and Limitations

| Advantages | Limitations |

| Small Particle Size: Capable of producing nano-scale dispersions and emulsions. | Energy Generation: High energy input can cause sample temperature to rise, necessitating cooling techniques. |

| High Efficacy: Delivers intense energy to the sample in very short processing times. | Limited Scalability: Best suited for low-to-medium volume processing; industrial scale-up requires additional equipment. |

| Compact Design: Ideal for benchtops in laboratory settings. | Probe Wear: Titanium probes may wear over time and require replacement to prevent contamination. |

| Non-contact Mixing: Reduces wear and contamination since only the probe contacts the sample. | Batch Processing: Generally unsuitable for continuous flow unless paired with specially designed flow cells. |

| Modifiable Parameters: Users can adjust amplitude, cycle duration, and duration to suit specific applications. | / |

What is High-pressure Homogenizer

High-pressure homogenizers are commonly employed in industries that require fine emulsification the reduction of particle size, as well as increased stability of the product. Their capacity to handle large volumes of material with a predictable performance makes them perfect for food processing, pharmaceuticals, cosmetics, biotechnology and more.

How Does a High-pressure Homogenizer Work

The working mechanism of the high-pressure homogenizer is based on pushing a liquid through a small valve at very high pressures, usually exceeding 1000 bar or more. As the liquid moves through this narrow gap it experiences extreme mechanical forces like shear, turbulence, as well as cavitation. The combination of forces alters particles and encourages the creation of stable and fine emulsions. This process leads to an even distribution of particle sizes that is essential for consistency in the quality of the product.

Key Applications of High Pressure Homogenizer

- Pharmaceuticals: In the process of formulating nanosuspensions, liposomes and injectable emulsions.

- Food and Beverages: Creates stable yogurt, milk sauces, juices, and sauces with improved flavor and shelf-life.

- Biotechnology: The process of disrupting mammalian and microbial cells in order to remove intracellular components.

- Cosmetics: Creates creamy emulsions to be used in creams, gels and lotions.

- Chemical Industry: Dispersing pigments and enhancing the uniformity of coatings and paints.

Advantages and Limitations

| Advantages | Limitations |

| Standardized Particle Size Reduction: Produces uniform micro- and nano-emulsions with precise size distribution. | High Cost: Maintenance and equipment are expensive, especially for industrial-scale models. |

| Scalable Output: Suitable for both laboratory research and industrial production. | Energy-intensive: Substantial energy is required to achieve high pressures. |

| Enhances Product Stability: Creates long-lasting suspensions and emulsions. | Heating Issues: Friction and compression can cause temperature increases, necessitating external cooling. |

| High Efficiency: Combines multiple forces, such as shear and cavitation, for rapid processing. | Risk of Clogging: Large particles or fibers may block the homogenization valve due to its narrow structure. |

| Closed System: Minimizes contamination risks and supports sterile or aseptic manufacturing environments. | Complex Maintenance: High-wear components like seals and valves need frequent inspection and repair. |

Key Differences Between Ultrasonic and High-Pressure Homogenizer

| Aspect | Ultrasonic Homogenizer | High-Pressure Homogenizer |

| Working Principle | Make use of ultrasonic waves that are high-frequency to induce cavitation | The force of liquid is exerted through a small valve with high pressure to cause shear as well as cavitation, impact, and shear. |

| Mechanical Force | Cavitation caused by ultrasonic vibration | High shear, turbulence and pressure drop |

| Particle Size Reduction | Ideal for small to medium-sized batches, all the way to nanoscale | Ideal for nano-emulsions as well as fine suspensions for large batches |

| Throughput | Usually low; ideal for small-scale lab or processing | High; perfect for industrial-scale continuous processing |

| Temperature Control | Might require cooling because of localized heat production | Creates a lot of heat, and often requires robust cooling systems |

| Sample Viscosity | It is most effective with low to medium viscosity samples | It can handle a greater range of viscosities, including those with high-viscosity. |

| Cell Disruption Efficiency | Highly effective for microbial and small cells. | Highly effective for durable and large-scale cell disruption. |

| Maintenance Requirements | Usually low; requires care for the transducer and cleaning of probes | The higher; it includes valve wear replacement, seals and pressure checks |

| Footprint and Portability | Small and lightweight; suited for benchtops | More complex and larger and more complex; usually used in industrial setups. |

| Cost | It is more affordable for laboratory applications | More initial investment and higher operating cost |

| Noise Level | It can be noisy due to ultrasonic pulses | Moderate mechanical noise depending on model |

Key Factors to Consider for Choosing Between Ultrasonic and High-Pressure Homogenizer

- Nature of the Sample

One of the main aspects to be considered is the kind of material you’re processing. Ultrasonic homogenizers perform exceptionally well for low – to medium-viscosity liquids, and are especially effective in delicate situations such as cell dispersion, lysis, or nanomaterials when precise control is required. However high-pressure homogenizers can manage more viscosities and viscosities that include highly viscous liquids, making them suited for more demanding industrial applications like making thick creams emulsifiable or processing liquids into slurries.

- Desired Scale and Throughput

The size of the processing process is a further aspect. Ultrasonic homogenizers tend to be used for smaller to medium-sized batches particularly when used in development and research facilities or laboratories because of their small dimensions and user-friendly. High-pressure homogenizers, however are made for large-scale production and have continuous flow capability, making ideal for industries that require large throughput and consistent results.

- Particle Size and Emulsion Stability

When the aim is to attain the reduction of extremely fine particles and extremely stable emulsions homogenizers with high pressure generally are the best choice. Their capability to apply powerful shear, cavitation, as well as impact forces at the same time results in a uniform distribution of particle size and enhanced product stability. Ultrasonic homogenizers also create fine dispersions however they will require longer processing time or multiple processes to attain the consistency possible with high-pressure systems.

- Heat Sensitivity of Materials

Both methods produce the same amount of heat, however the degree and level of control vary. Ultrasonic homogenization may result in localized heat around the probe. This could cause heat-sensitive materials to be damaged if external cooling is used. Homogenization with high pressure tends to produce more heat because of the compression of the fluid and rapid pressure fluctuations which often require the use of integrated cooling devices. So, taking into consideration the temperature sensitivity of your material is crucial when deciding between these methods.

- Maintenance and Operational Costs

Complexity of operation and maintenance are the main issues that need to be addressed. Ultrasonic homogenizers typically require less maintenance, but they do require regular clean-up of the probe as well as monitoring the condition of the transducer. High-pressure homogenizers are more complex and have components like valves, seals, pumps and valves which require periodic inspection and repair, adding the cost of maintenance and time. Furthermore, high-pressure homogenizers typically use more energy due to the force they require.

- Budget and Space Constraints

Physical footprint and cost could impact the choice. Ultrasonic homogenizers tend to be cheaper and are smaller in footprint, making them ideal for laboratories or facilities with smaller space. In contrast, high-pressure homogenizers are an investment in capital that is larger and require more space, frequently necessitating a dedicated infrastructure.

Ultrasonic homogenizers are economical and ideal for lab-based, small-scale applications where moderate reduction of particle size is enough.

High-pressure homogenizers are suitable in commercial environments, offering greater particle quality and scalability, but with a higher operating cost.

Final Thoughts

High-pressure homogenizers and ultrasonic homogenizers are effective instruments for creating high-quality emulsions, as well as particle size reduction, however they have different functions. Ultrasonic homogenizers are ideal for precise work and delicate samples in small quantities and high-pressure homogenizers excel in large-scale, robust production environments. Understanding the specific needs of your project will help you make the most appropriate choice between these two techniques.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.