As the demand for plant-based foods continues to soar, innovative preservation methods are crucial for maintaining the quality, flavor, and nutritional value of these products. freeze drying has emerged as a powerful technique for maintaining the quality of plant-based foods. In this article, we explore the significance of freeze dryers in revolutionizing the preservation of plant-based foods.

Understanding Freeze Dryers

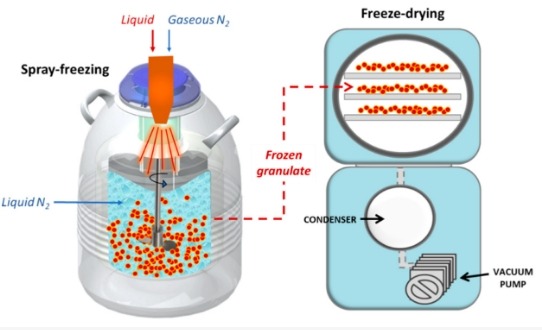

Freeze dryers, also known as lyophilizers, are sophisticated pieces of equipment designed to remove moisture from foods while preserving their structure and properties. The process involves freezing the food product and then subjecting it to a vacuum environment, where the frozen water is converted directly into vapor through a process called sublimation. This gentle dehydration method preserves the food’s texture, flavor, and nutritional content, making freeze-dried products highly sought after in the food industry.

The Freeze Drying Process

1. Freezing

The first step in the freeze drying process involves freezing the material to be dried. This freezing step is essential for forming ice crystals uniformly throughout the substance. The material is typically cooled to temperatures below its freezing point using refrigeration or liquid nitrogen.

2. Primary Drying (Sublimation)

Once the material is frozen, it is transferred to a vacuum chamber where the pressure is reduced to create a low-pressure environment. Heat is then applied to the material, causing the ice to undergo sublimation—transitioning directly from a solid to a gas without passing through the liquid phase. This process removes the majority of the moisture from the material, leaving behind a freeze-dried product with a porous structure.

3. Secondary Drying (Desorption)

After primary drying, the freeze-dried material still contains some residual moisture. To remove this remaining moisture and ensure the stability of the product, secondary drying is performed. During this stage, the temperature of the material is slightly raised, and vacuum pressure is maintained to facilitate the removal of any remaining water molecules through desorption.

4. Packaging

Once the freeze drying process is complete, the dried material is ready for packaging. The freeze-dried product is typically packaged in airtight containers or vacuum-sealed bags to protect it from moisture and oxygen, which could cause deterioration. Proper packaging helps maintain the quality and shelf life of the freeze-dried product.

Benefits of Freeze Dryers for Plant-Based Foods

1. Retention of Nutritional Value

Freeze drying preserves the nutritional integrity of plant-based foods by minimizing exposure to heat and oxygen during the dehydration process. This helps retain essential vitamins, minerals, antioxidants, and phytonutrients, ensuring that consumers receive maximum nutritional benefits from the food.

2. Preservation of Flavor and Texture

Unlike traditional drying methods, which can lead to flavor loss and textural changes, freeze drying maintains the natural taste, aroma, and texture of plant-based foods. This results in products that retain their original flavors, colors, and structures, appealing to consumers who seek high-quality, flavorful food options.

3. Extended Shelf Life

By removing moisture from foods, freeze drying inhibits microbial growth and enzymatic reactions that cause spoilage. This significantly extends the shelf life of plant-based foods, reducing the need for preservatives and additives while ensuring product freshness and quality over time.

4. Lightweight and Convenient

Freeze-dried plant-based foods are lightweight, compact, and have a low moisture content, making them convenient for storage, transportation, and on-the-go consumption. Their reduced weight and volume also contribute to lower shipping costs and reduced environmental impact compared to fresh or traditionally dried foods.

5. Versatility in Culinary Applications

Freeze-dried plant-based foods can be easily rehydrated by adding water, making them versatile ingredients for a variety of culinary applications. From soups and stews to smoothies, salads, and snacks, freeze-dried fruits, vegetables, herbs, and meat alternatives add flavor, texture, and nutrition to a wide range of dishes.

6. Reduction of Food Waste

Freeze drying helps reduce food waste by extending the shelf life of perishable plant-based foods. By preserving the freshness and quality of fruits, vegetables, and other produce, freeze dryers enable manufacturers, retailers, and consumers to minimize spoilage and make better use of food resources.

7. Minimal Processing and Additives

Freeze drying is a gentle dehydration method that requires minimal processing and does not involve the use of chemical additives or preservatives. This makes freeze-dried plant-based foods a healthier and more natural alternative to heavily processed or preserved foods.

Applications and Future Trends in Freeze Dryers for Plant-Based Foods

Freeze dryers have a wide range of applications in the preservation and processing of plant-based foods, and they continue to evolve to meet the changing demands of consumers and the food industry.

1. Expanded Product Range

Freeze dryers enable the production of a diverse range of plant-based food products, including fruits, vegetables, herbs, grains, legumes, and meat alternatives. Future trends may see an expansion of product offerings to include more exotic and specialty plant-based ingredients, catering to diverse consumer preferences and dietary requirements.

2. Functional Foods and Ingredients

Freeze-dried plant-based ingredients are increasingly used in the formulation of functional foods and beverages designed to provide specific health benefits beyond basic nutrition. Future trends may include the development of freeze-dried ingredients with enhanced functional properties, such as improved bioavailability of nutrients, added probiotics or prebiotics, and targeted health-promoting compounds.

3. Ready-to-Eat Meals and Snacks

Freeze drying enables the production of convenient, shelf-stable meals and snacks made from plant-based ingredients. Future trends may see the development of innovative freeze-dried meal solutions tailored to meet the needs of busy consumers looking for healthy, on-the-go options, such as freeze-dried soups, salads, smoothie mixes, and snack bars.

3. Premium and Gourmet Products

Freeze-dried plant-based foods are often perceived as premium and gourmet products due to their superior quality, flavor, and nutritional value. Future trends may involve the expansion of premium freeze-dried product lines targeting discerning consumers willing to pay a premium for high-quality, artisanal plant-based foods made from locally sourced, organic ingredients.

4. Customization and Personalization

Freeze dryers offer opportunities for customization and personalization of plant-based food products to meet individual preferences and dietary needs. Future trends may include the development of customizable freeze-dried meal kits, allowing consumers to create personalized dishes by selecting their preferred ingredients and flavors.

5. Sustainable and Ethical Sourcing

With growing consumer interest in sustainability and ethical sourcing, future trends in freeze dryers for plant-based foods may involve the adoption of environmentally friendly practices, such as sourcing ingredients from certified organic, fair trade, and regenerative agriculture suppliers. Additionally, advancements in freeze drying technology may lead to improvements in energy efficiency and waste reduction, further enhancing the sustainability of plant-based food production.

6. Integration of Technology and Automation

Future trends in freeze dryers may involve the integration of advanced technology and automation systems to streamline production processes, improve product quality and consistency, and reduce labor costs. This may include the use of artificial intelligence, robotics, and data analytics to optimize freeze drying cycles, monitor product quality, and ensure compliance with food safety standards.

Conclusion

Freeze dryers are revolutionizing the preservation of plant-based foods by preserving their flavor, texture, and nutritional value while extending their shelf life. With their ability to produce lightweight, convenient, and shelf-stable products, freeze dryers are poised to play a significant role in meeting the demands of health-conscious consumers. As the plant-based food market continues to evolve, freeze drying technology will continue to drive innovation and shape the future of food preservation.