A freeze dryer is a technical method that pre-freezes water-containing items, and then sublimates its moisture in a vacuum state to obtain dry items. The freeze-dried articles are easy to be stored for a long time and can be restored to the state before freeze-drying and maintain the original biochemical properties after adding water.

Vacuum freeze-drying technology has a wide range of applications in bioengineering, pharmaceutical industry, food industry, material science, and deep processing of agricultural and sideline products, and the scale and field are still expanding. To this end, vacuum freeze-drying will become an important application technology in the 21st century.

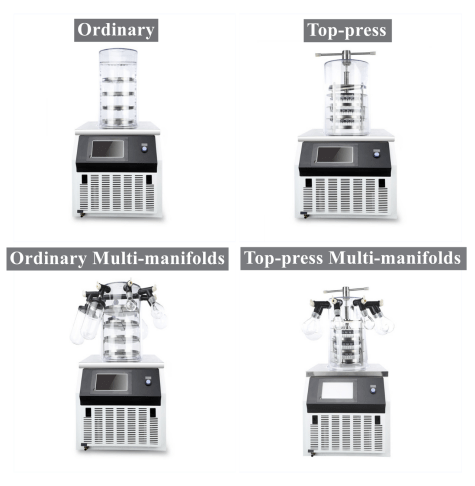

The structure of the Lab freeze dryer

The freeze dryer is composed of a refrigeration system, a vacuum system, a heating system, and an electrical instrument control system. The main components are the drying box, condenser, refrigeration unit, vacuum pump, heating/cooling device, etc.

The refrigeration system is the most important part of the freeze dryer and is called the “heart of the freeze dryer”. Its refrigeration system is mainly composed of the following components: compressor, refrigerant, oil separator, water condenser, filter drier, intercooler, sight glass, solenoid valve, hand valve (top cover valve), expansion valve, evaporation (plate exchanger, rear box condensing coil), vapor-liquid separator, return air filter, pressure gauge, pressure control relay, CPCE (energy regulator), safety valve, refrigeration pipeline, etc.

How does Freeze Dryer work?

Freeze drying is a drying technology using the principle of sublimation. It is a process of quickly freezing the dried material at low temperature, and then directly sublimating the frozen water molecules into water vapor in a suitable vacuum environment. Freezing The product obtained by drying is called a lyophilizer, and the process is called lyophilization.

The working principle of the freeze dryer is that after the liquid refrigerant absorbs the heat of the cooled material in the evaporator, it is vaporized into low-pressure and low-temperature steam, which is inhaled by the compressor, compressed into high-temperature and high-pressure steam, and then discharged into the condenser. It releases heat to the cooling medium (water or air), condenses into a high-pressure liquid, is throttled by a throttling device to a low-pressure and low-temperature liquid, and enters the evaporator again to absorb heat and vaporize.

How to choose a freeze dryer?

When choosing a freeze dryer, you need to pay attention to many specific details. Customers need to buy a freeze dryer that suits them according to their needs. When purchasing a freeze dryer, it is not only necessary to consider the price of the freeze dryer, but also the temperature of the cold trap, the cooling rate, the temperature uniformity of the board, the flatness, and other indicators.

Cold Trap Temperature

The cold trap is a device for trapping water in the freeze-drying process. In theory, the lower the temperature of the cold trap, the stronger the water trapping ability of the cold trap. The cold trap temperature of the experimental series freeze dryer mainly has several grades such as about -45°C, about -60°C, and about -80°C. Freeze-drying with a cold trap temperature of -45°C is suitable for some products that are easy to freeze-dry. Freeze-drying machines with a cold trap temperature of about -60°C are suitable for freeze-drying of most products. Freeze-drying with a cold trap temperature of -80°C It is suitable for lyophilization of some special products. The effect of cold trap temperature on the water-capturing ability was experimentally demonstrated that when the temperature of the cold trap dropped from -35°C to -55°C, the water-capturing capacity was significantly improved. Therefore, in the absence of special requirements, it is an ideal choice to use a cold trap temperature of about -60 °C.

Cooling Rate

The cooling rate reflects the cooling capacity of the refrigeration system. Under no-load conditions, the temperature of the cold trap should reach the minimum temperature specified in the index within 1 hour. For example, for a freeze dryer with a cold trap temperature ≤ -60 °C, the machine starts timing from the time the machine is turned on for refrigeration, and the time for the cold trap temperature to reach -60 °C should not exceed 1 hour.

Ultimate Vacuum

The ultimate vacuum degree reflects the leakage of the freeze dryer and the pumping efficiency of the vacuum pump. The vacuum degree of the freeze-drying box. In the past, the higher the vacuum degree, the better. The current point of view is that the vacuum degree should be within a reasonable range. The vacuum degree is too high, which is not conducive to heat transfer, and the drying speed decreases, but in any case, the no-load limit vacuum degree of the freeze-drying box should reach more than 15Pa.

Plate Temperature Uniformity And Flatness

The uniformity and flatness of the plate temperature have a great influence on the uniformity of product quality. The better the temperature uniformity and flatness, the better the uniformity of freeze-dried product quality. Freeze dryer shelf temperature control has heater type and intermediate fluid type. The freeze dryer shelf with an intermediate fluid control layer has good temperature uniformity and flatness. This freeze dryer plate layer is a hollow sandwich structure. The cooling and heating of the plate are realized through the circulation of the intermediate fluid in the fluid channel inside the plate, so the temperature of the plate is uniform. The freeze dryer uses the technology of the fluid in the middle of the shelf. The shelf temperature control of the bell-type freeze dryer uses a heater, and the temperature consistency of the plating layer is slightly worse. But in general, the temperature difference between the layers of the medical freeze dryer should be controlled within ±1.5 °C, and the temperature difference inside the plate should be ±1 °C, and the food freeze dryer can be appropriately relaxed.

Summarize

From the above content, we can conclude – choose different types of laboratory freeze dryers depending on the industry. As the most successful freeze dryer manufacturer in China, DRAWELL has been supplying high-quality freeze dryers to laboratories all over the world for many years. If your laboratory needs a freeze dryer or other laboratory equipment, please contact us, we will be your best choice.