Biosafety level (BSL) laboratories handle dangerous biological substances, and require strict sterilization procedures to prevent contamination and ensure the safety of employees. As a key piece of equipment within these labs, vertical autoclaves play a crucial role in the decontamination of instruments, waste and media. Their designs, performance and conformity to biosafety regulations make them essential for BSL-2, BSL-3, and BSL-4 facilities.

What are the Biosafety Levels and the Need for Autoclaving

Biosafety levels vary from BSL-1 that is a minimal risk microorganisms to BSL-4 in which highly hazardous and exotic pathogens such as Ebola virus are dealt with. As the biosafety levels increase as does the need for strict sterilization and containment procedures.

Autoclaving, or steam sterilization, is the most efficient method of eliminating the microbial life that includes virus spores, spores, and bacteria. In BSL labs vertical autoclaves are the most popular because of their small size as well as safety features and ability to handle large quantities of waste that is infectious.

Why Vertical Autoclaves are Preferred in BSL Laboratories

1. Space Efficiency in High-Containment Environments

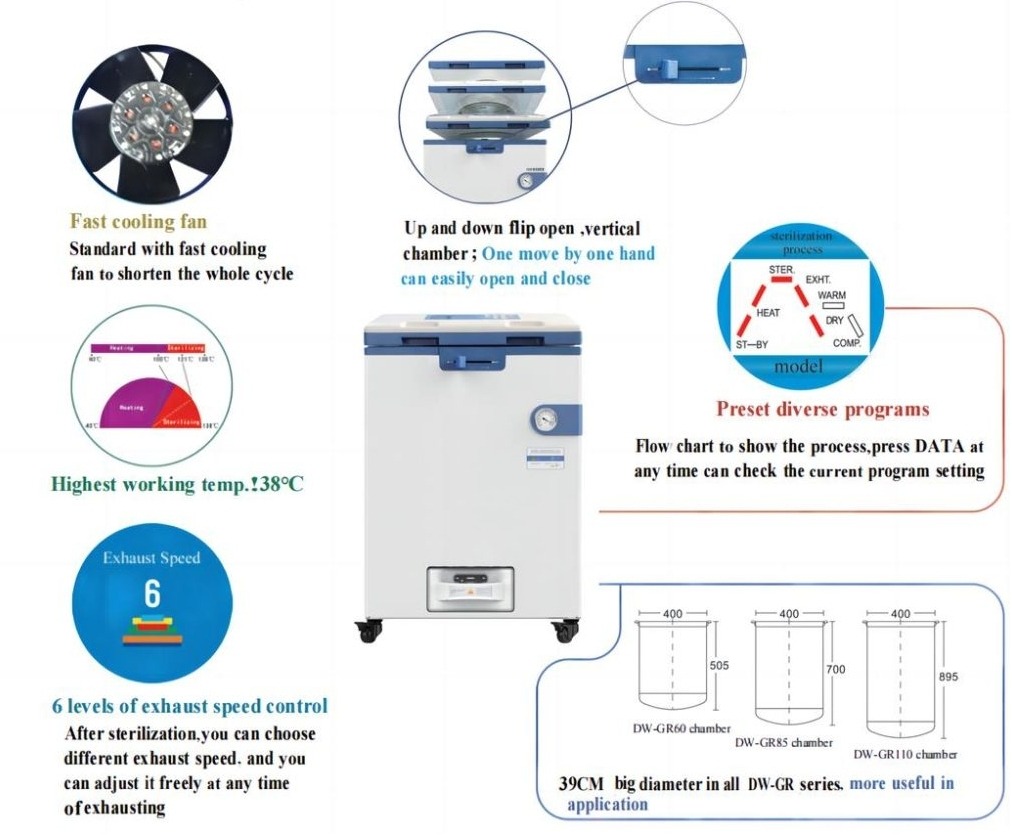

One of the best benefits of using vertical autoclaves are their small top-loading design. A lot of BSL labs, particularly those that operate in BSL-3 or BSL-4 are highly organized environments, where the movement of individuals is limited by personal protective equipment as well as space constraints. Vertical autoclaves need less area than floor area than horizontal models, which makes them perfect for installations in biosafety cabinets and small prep rooms where maximising the square meters of space is vital.

2. Enhanced Safety and Containment Features

BSL laboratories handle pathogens with varying danger from low-level microbes to deadly viruses. Vertical autoclaves specifically designed for these environments come with advanced features for containment like airtight lids for sealing as well as pressure interlocks and filtering systems for exhaust that are HEPA. These features are crucial in keeping out toxic aerosols and steam from the process of sterilization. For BSL-3 or BSL-4 labs with passing-through (double-door) Autoclaves that are vertical are able to be incorporated in the lab’s wall to ensure directional workflows and to ensure air pressure is contained between clean and contamination zones.

3. Reliable Sterilization for Diverse Biological Loads

BSL labs process a diverse variety of biological materials, from glassware and culture media to PPE and infectious waste. Vertical autoclaves provide a solid sterilization in a variety of load densities and types. Their distribution of steam is uniform and extends into both porous and solid objects and ensures the elimination of all microorganisms, which includes the spores of resistant bacteria. A lot of models permit custom cycles to meet particular sterilization requirements for various materials, making them extremely flexible in routine lab work.

4. Ease of Use and Maintenance

Despite their advanced purpose, vertical autoclaves are typically simpler to use, load and maintain than heavier horizontal models. Top loading allows personnel to load instruments and waste containers with the least physical stress. The features that are automated, such as the digital controls panels automatic water fill systems and real-time cycle monitoring — reduce errors by the operator and limit the handling and disposal of infectious substances which is crucial in a biosafety-sensitive setting.

5. The Compliance With Biosafety and Regulatory Standards

BSL laboratories must be in compliance with national and international regulations on biosafety that include WHO, CDC, and ISO standards. Vertical autoclaves utilized in these labs are usually designed to meet or surpass the sterilization and containment requirements established in these bodies. The built-in data logging system cycle validation, cycle logging, and sterilization records provide complete traceability, an essential necessity for audits of laboratories and for compliance within research and clinical setting.

Key Features of Vertical Autoclaves for Biosafety Level Labs

- Top-Loading Vertical Design: The top-loading configuration, vertical design of these autoclaves make them efficient in space and simpler to place in small laboratory spaces. This configuration is particularly beneficial when it comes to BSL-3 and BSL-4 labs, where space is controlled tightly and every square meter needs to be optimized.

- Airtight Lid and Safety Interlocks: To avoid the risk of accidental exposure to steam or infectious agents, autoclaves in vertical configurations come outfitted with sealed airtight lids as well as electronic or mechanical safety interlocks. The mechanisms in place ensure that the chamber will not be opened until the temperature and pressure levels have been restored to safe levels.

- HEPA-Filtered Exhaust Systems: Controlling exhaust is essential for biosafety labs. HEPA filters integrated into exhaust systems hinder the release of contaminated steam or aerosols during and after sterilization, making sure that the surrounding area remains safe and sterile.

- Pass-Through (Double-Door) Configuration (Optional): To be used in BSL-3 or BSL-4 labs Vertical autoclaves are equipped with pass-through capabilities which allow sterilized substances to be moved from contaminated areas to clean areas with no cross-contamination. This enables a one-way workflow, which is a crucial requirement for high-containment labs.

- Programmable Sterilization Cycles: Advanced microprocessor controls enable people to set up and modify sterilization cycles according to materials’ type and size. This flexibility allows for the safe sterilization of all kinds of biohazardous waste, laboratory instruments as well as culture media and PPE.

- Built-in Cycle Validation and Data Logging: Traceability and compliance are essential when working in labs with strict regulations. Vertical autoclaves that are used in BSL labs usually include integrated process validations, electronic record keeping and USB or network-based data export options to help with the quality assurance process and regulatory audits.

- Automatic Water Filling and Drainage: To limit contact by operators with the components that are contaminated Many vertical autoclaves have automatic water drainage and filling systems. This increases safety, minimizes interventions by hand, and enhances productivity of the workflow.

- Corrosion-Resistant Stainless Steel Chamber: The chamber’s inner part is usually constructed of 304 or 316 grade stainless steel, which has a an excellent resistance to chemical and corrosion. This provides durability and durability in the most demanding laboratory conditions.

- Temperature and Pressure Sensors with Digital Display: Monitoring of sterilization conditions in real-time is vital for ensuring the correct performance of the cycle. Digital vertical autoclaves have precise sensors as well as digital displays that display the current temperature, pressure and time, ensuring that operators are well-informed and on top of their game.

- Alarm Systems and Emergency Cutoff: If there is a abnormality within the system — such as overheating, overpressure or electrical problems, alarm systems built into the system and emergency shut-off mechanisms provide prompt response and protect the integrity of both lab and user.

Applications of Vertical Autoclaves in Different Biosafety Levels

This chart provides how vertical autoclaves change in terms of complexity and integration based on the biosafety levels that serves essential sterilization functions as well as biocontainment needs.

| Biosafety Level | Pathogen Risk Level | Application of Vertical Autoclaves | Typical Sterilized Materials |

| BSL-1 | Low-risk agents (non-pathogenic) | Basic sterilization of lab items to ensure hygiene in the lab | Glassware, culture media, plastic lab tools |

| BSL-2 | Moderate-risk agents (e.g., Hepatitis B, Salmonella) | Disposal of waste that is safe and decontamination of equipment that is reusable | Tip tips for pipes, Biohazard Waste lab coats, instruments that can be reused |

| BSL-3 | High-risk airborne pathogens (e.g., Mycobacterium tuberculosis) | Integrated into the containment workflows, employed to sterilize waste before disposing of it | Infectious culture, sealed waste bags, respirator parts, and other components |

| BSL-4 | Life-threatening pathogens (e.g., Ebola, Marburg virus) | Sterilization through the passageway between clean and contaminated zones; vital in the process of neutralizing waste | Complete PPE set, high-level biohazard waste, lab waste sealed bins |

Key Factors to Consider for Choosing the Right Vertical Autoclave in BSL Labs

Selecting the right vertical autoclave suitable for biosafety laboratories is an essential choice that has a direct impact on the safety of sterilization, sterilization efficiency as well as workflow efficiency and compliance with regulations. BSL laboratories operate under strict biosafety standards, particularly in higher grades (BSL-3 as well as BSL-4) and BSL-4, which is why it’s crucial to align the features of equipment with the operational requirements.

- Biosafety Level Requirements

Each BSL level comes with a specific sterilization and containment procedures. for BSL-1 and BSL-2 conventional vertical autoclaves are sufficient. But, BSL-3 and BSL-4 require autoclaves that have advanced containment capabilities like HEPA-filtered exhausts, airtight seals as well as pass-through (double-door) features. Selecting an autoclave that meets or surpasses the biosafety level’s security and technical specifications is vital.

- Capacity and Load Volume

Laboratories vary in the amount and kind of material they require to sterilize. Select an autoclave that has chamber capacity that is compatible with the typical load of your laboratory. A chamber that is too small will cause workflow to be slowed down; too large could waste energy. Think about the internal basket configurations that can accommodate different sizes of waste bags.

- Space Constraints and Installation Environment

Vertical autoclaves are favored in areas with limited space because of their top loading design. It is nevertheless essential to have enough clearance over the unit to allow lid operation, and also around it to allow for the ventilation as well as maintenance. The wall-integrated models or the recessed pass-through models could be required in areas with high levels of containment.

- Safety Features

Find safety features that are comprehensive including lid locking mechanisms and pressure relief systems that are automatic as well as over-temperature protection and emergency stop mechanisms. They are essential in avoiding exposure of the operator to biological agents that pose a risk or steam-related incidents.

- Exhaust and Filtration Systems

Exhaust systems must comprise HEPA as well as ULPA filters to stop the aerosols from escaping during sterilization cycles, which is especially important when working in BSL-3 or BSL-4 environments. Certain models include filtering of vacuum pumps and neutralizers for condensate that can further improve biosafety.

- Cycle Programmability and Control Interface

A user-friendly control panel that has sterilization cycles that are programmable allows users to adjust settings for various kinds of materials, such as liquids, solids or waste. Choose models that offer precise control of temperature, pressure and duration. They also have easy-to-use digital interfaces.

- Data Logging and Compliance Documentation

BSL labs need to keep documents of sterilization to aid in audits and quality control. Use autoclaves that include built-in data logs with USB/export capability, as well as Cycle validation records. This helps ensure conformity with biosafety as well as quality management systems, such as ISO 13485 and GMP standards.

- Ease of Maintenance and Service Access

Access to maintenance is crucial in areas with high levels of congestion. Think about autoclaves with self-diagnostic features as well as modular components and the ability to monitor remotely. Auto-cleaning cycles and corrosion-resistant chambers will reduce the the burden of maintenance over time.

- Integration into Containment Workflow

Within BSL-3 and BSL-4 labs, sterilizers have to integrate seamlessly into the workflow. Autoclaves that pass through clean and dirty zones assist ensure that materials are moved in a uniform manner. Integrity with biosafety cabinets and Negative pressure equipment is an important consideration.

- Manufacturer Reputation and Support

Select a trusted manufacturer with years of experience in biosafety. Support for training, installation as well as preventive maintenance and emergencies is essential particularly in critical environments such as BSL-3 as well as BSL-4 labs.

Drawell is a trusted manufacturer of vertical autoclaves recognized for providing safe sterilization solutions designed to meet the demanding requirements of biosafety-level labs. Vertical autoclaves supplied by Drawell are designed with modern features like precise temperature control exhaust systems that are HEPA-filtered and sterilization cycles that can be programmed. With professional technical support and in compliance with international standards of biosafety, Drawell ensures safe and efficient sterilization in clinical research, research, and high-containment laboratories.

Final Thoughts

Vertical autoclaves are a crucial element in biosafety labs, which ensures the safety and effectiveness of sterilization of infectious waste and instruments that can be reused. Their small size, their containment capabilities, and compliance with strict sterilization requirements are the best for the highly-risk environment that are found in BSL-3 and BSL-4 laboratories. For labs that handle hazardous biological agents, a certified vertical autoclave is more than an option and it’s a requirement.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.