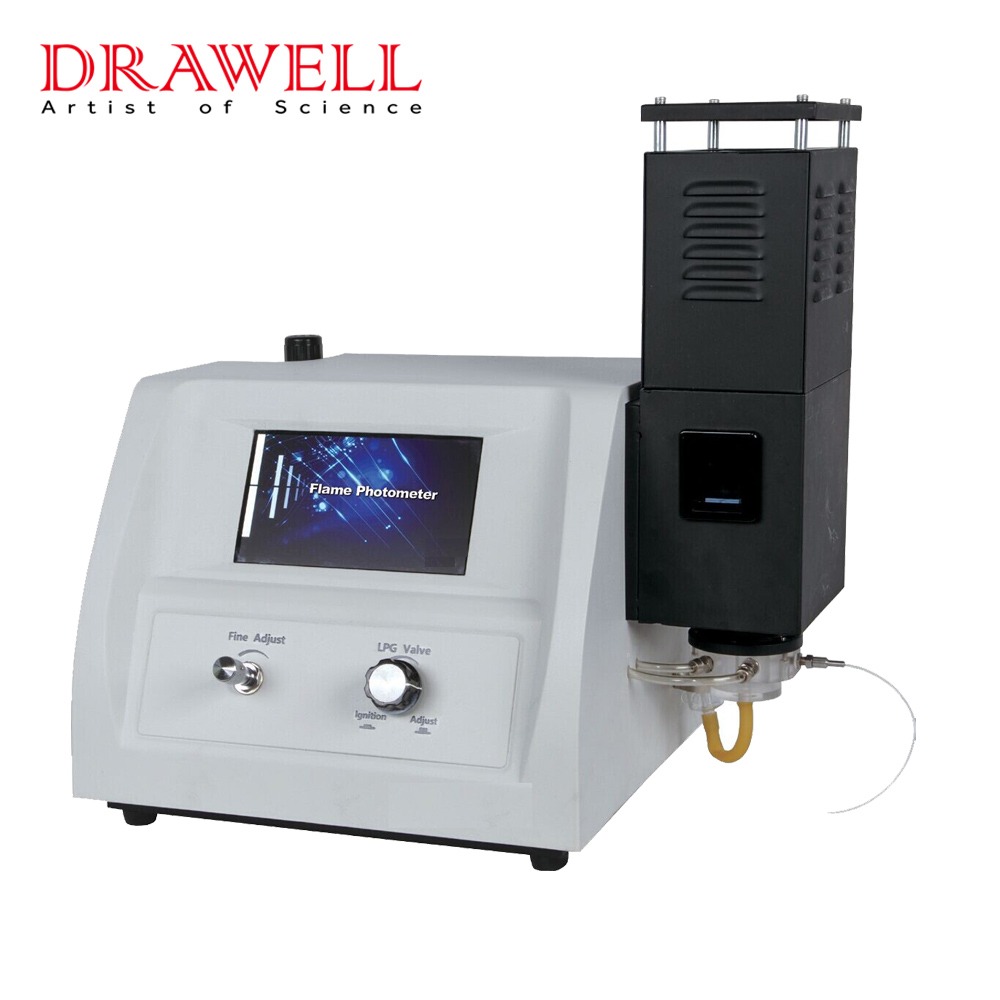

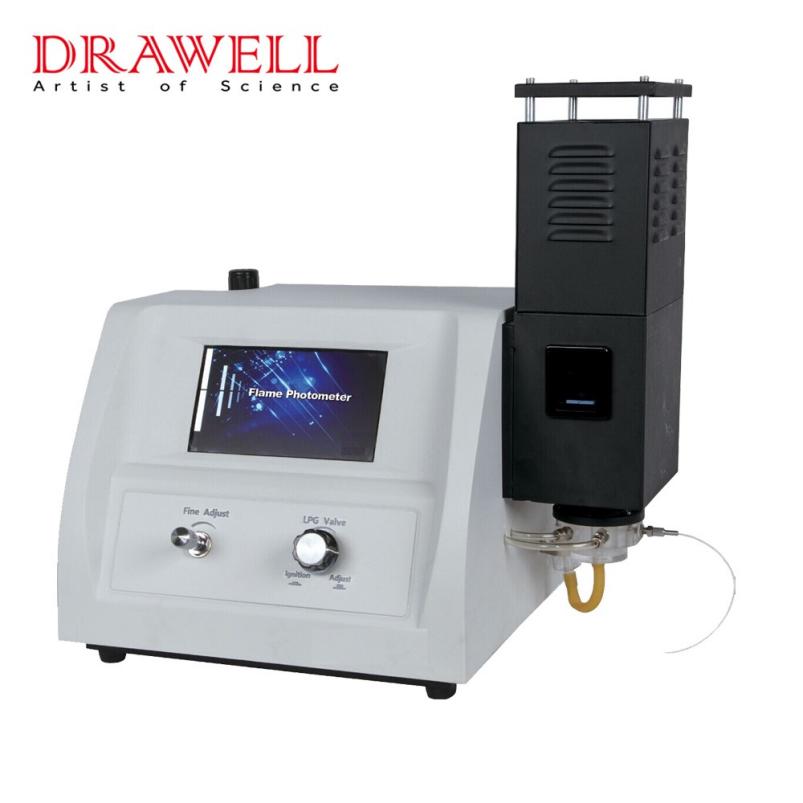

A flame photometer refers to an analytical instrument based on the principle of emission spectroscopy. It uses flame as the excitation light source and applies a photoelectric detection system to measure the radiation intensity emitted by the excited element when it returns from the excited state to the ground state. According to its characteristics, Spectrum and light wave intensity determine element type and its content.

It includes a gas and flame combustion part, an optical part, a photoelectric converter, and a detection and recording part. The temperature of the flame is relatively low, so only a few elements can be excited, the obtained spectrum is relatively simple, and the P disturbance is small. Flame photometry is especially suitable for the determination of easily excited alkali metal and alkaline earth metal elements.

3 Reasons That Affect Flame Photometer Analysis

For the flame photometer, although the content of the element to be measured is theoretically proportional to the intensity of its emission spectrum, it is generally only suitable for quantitative analysis of alkali metals and alkaline earth metals in a certain concentration range due to the limitation of excitation energy. Three factors that affect flame photometer analysis are described below:

1. Excitation conditions:

a) Flame temperature: if the temperature is too low, the sensitivity will decrease, and if the temperature is too high, the alkali metal ionization will be serious, which will affect the linear relationship of the measurement;

The factors that affect the flame temperature are as follows:

Gas type: It is more suitable and convenient to use low-temperature flames (about 1900℃) such as propane-air, butane-air, or liquefied petroleum gas-air;

The ratio of gas to auxiliary gas: keep it appropriate;

The suction amount of the sample solution: if it is too large, the flame temperature will drop.

b) Gas pressure: the gas pressure should be kept constant during measurement;

c) Sprayer: If the sprayer is not clean, it is easy to cause poor atomization of the test solution. During the measurement, the test solution must be clear, and the sprayer should be cleaned with water or ethanol at any time;

d) Liquid level: the change in liquid level will cause the element concentration after excitation to change, and the test height should be kept consistent during measurement.

2. The type and composition of the sample:

a) The ionization and self-absorption of elements can lead to the curvature of the calibration curve, and the linear range is narrowed: for example, the self-absorption of potassium is serious at high concentrations, so that the calibration curve is bent in the direction of the abscissa; The curve bends in the direction of the ordinate;

b) The coexistence of ions in the sample influences the determination: for example, when the alkali metals coexist, the spectral line is enhanced, which makes the result on the high side;

c) The physical properties of the sample should be consistent with the composition of the standard solution;

3. Instrument quality:

a) Selectivity of the monochromator: the filter quality is good, which can reduce the interference of coexisting substances;

b) The influence of the surrounding environment on the instrument;

c) Photocells are fatigued after being used for a long time.

What Should You Do If the Flame Photometer Fails?

Any instrument will face more or fewer failures during use, and the flame photometer is no exception. Next, this article will take the FP640 flame photometer as an example to explain some problems that may exist during its use and the corresponding treatment methods.

Common faults include the following: no discharge, no spark with discharge sound, no ignition due to liquefied odor in the combustion chamber, no liquefied odor in the combustion chamber, unstable flame, unregulated air pressure, no sample injection, no display screen, etc. The details are as follows:

1. When the instrument is in use, the pressure gauge should indicate between 0.12-0.15 mpa. When ready, press the ignition button lightly, and no discharge sound can be heard. Observe the glass window, no sparks, and no discharge.

Treatment method: Open the upper cover of the instrument, check the power circuit board, and whether there is a 5 V voltage output to the igniter. If not, you need to check the transformer output on the main control power supply circuit board. This fault is more common, and you can replace the transformer. If there is a 5 V voltage, you need to check whether the pulse generator is damaged, and the fault can be solved by replacing it.

2. During the ignition process, you can hear a “da-da-da” sound, observe the glass window, and there is no spark.

Treatment method: There is a discharge sound and no spark when igniting, most of which are the fault of the discharge circuit. Remove the glass draft shield, check the distance between the ignition contact and the combustion head, clean the combustion head, and ignite without gas to see if there is an arc. If not, check the grounding wire and check if the ignition wire is open. After removing the above faults, if the ignition still has no spark, you can only replace the igniter to solve the fault.

3. The instrument is turned on, the air compressor is working normally, and the pressure gauge indicates normal, open the gas valve and the injection switch, and you can smell the liquefaction smell, press the ignition switch, and it will not ignite.

Treatment method: First, consider whether the gas adjustment is suitable. The gas adjustment valve rotates clockwise from small to large, generally at a position of about 2 to 3 turns. Too low or too high a gas concentration may result in a misfire. If it still does not light after adjustment, immediately close the injection valve and gas valve, remove the glass draft shield of the combustion pool, and adjust the positions of the ignition head and the combustion head to eliminate this fault.

4. The instrument is turned on, the air compressor is working normally, the pressure gauge indicates normal, open the gas valve and the injection switch, no liquefaction smell can be smelled, and the ignition switch cannot be ignited.

Treatment method: This fault indicates that no liquefied gas is sent to the combustion head, and the liquefied gas path needs to be checked. Starting from the liquefied gas tank, check the pressure-reducing valve, gas valve, atomizer, and combustion head at one time. It is common that the combustion head is blocked and needs to be cleaned.

5. After the instrument is powered on, turn it on, and turn on the injection switch and the gas switch, there is a flame after ignition, but the flame is unstable.

Treatment method: The flame is unstable after ignition. Generally, adjust the size of the gas valve first. Observe through the observation window. The flame height should be controlled at 2-3cm. The flame should be blue when the air sample is injected. If the flame cannot be controlled by adjusting the gas valve, consider that the solenoid valve in the gas valve is not open, try to adjust the thermocouple to get close to the flame, and observe the change of the flame. If not, consider whether the thermocouple is damaged, and this should be eliminated after replacement. Fault.

6. During the operation of the instrument, the air pressure should be stable. Once the pressure is unstable, it will affect the sampling process, atomization process, combustion flame, etc., which will affect the measurement results.

Treatment method: Check along the air path of the air compressor, focusing on checking the air filter for air leakage and blockage. If it is damaged, it must be replaced in time to eliminate the fault.

7. The instrument is turned on normally, the ignition is also normal, and the pressure indicator is also normal, but the sample is not injected.

Treatment method: If the sampling needle does not inject samples, firstly check whether the sampling capillary is blocked, dredged, or replaced, and secondly, it is necessary to rule out whether the atomizer is faulty. The quality of the atomization effect of the atomizer is directly related to the accuracy of the measurement data. . When the air compressor can be turned on again and the gas circuit is closed, the nebulizer is c.