Atomic absorption spectrophotometer (hereinafter referred to as AAS) will decrease in sensitivity after using it for some time. This will directly lead to an increase in the detection limit of the instrument, even exceeding the requirements of the verification regulations, so it is judged to be unqualified. The following takes flame atomization atomic absorption as an example to analyze the reasons for the decrease in sensitivity and the corresponding countermeasures.

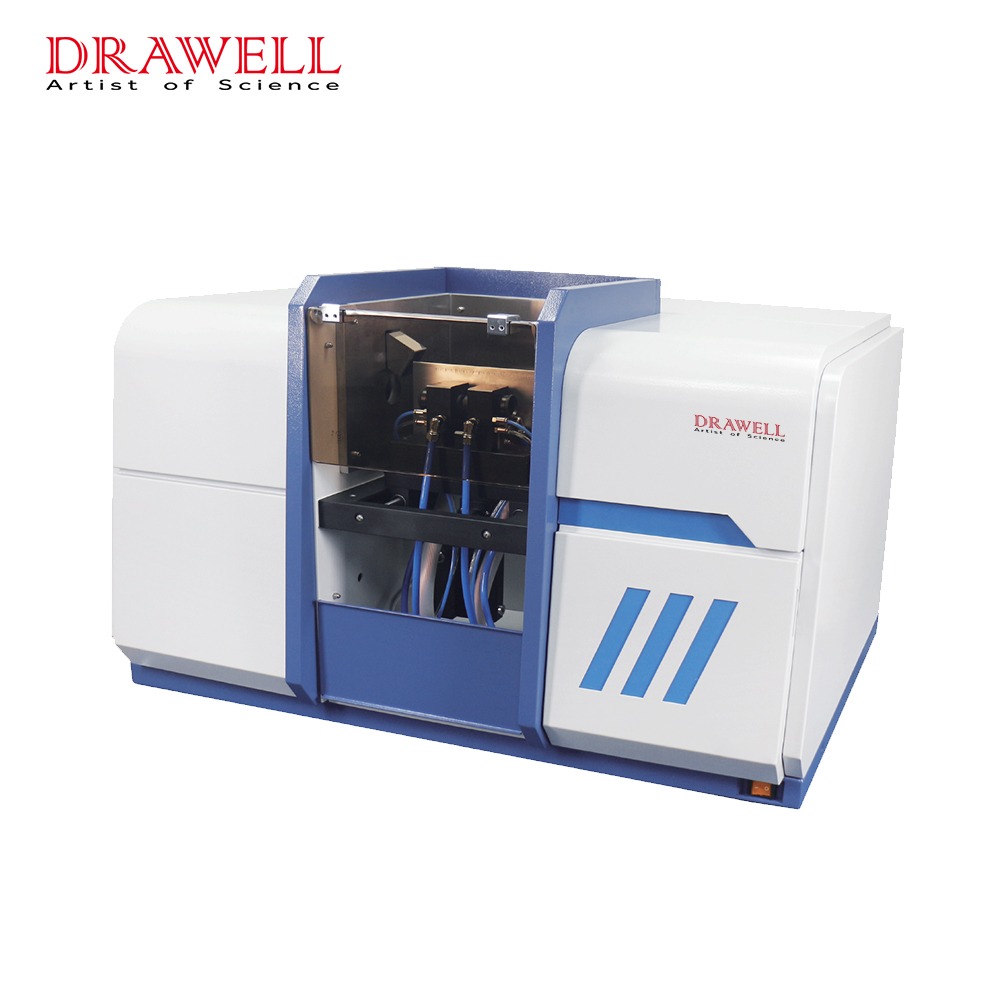

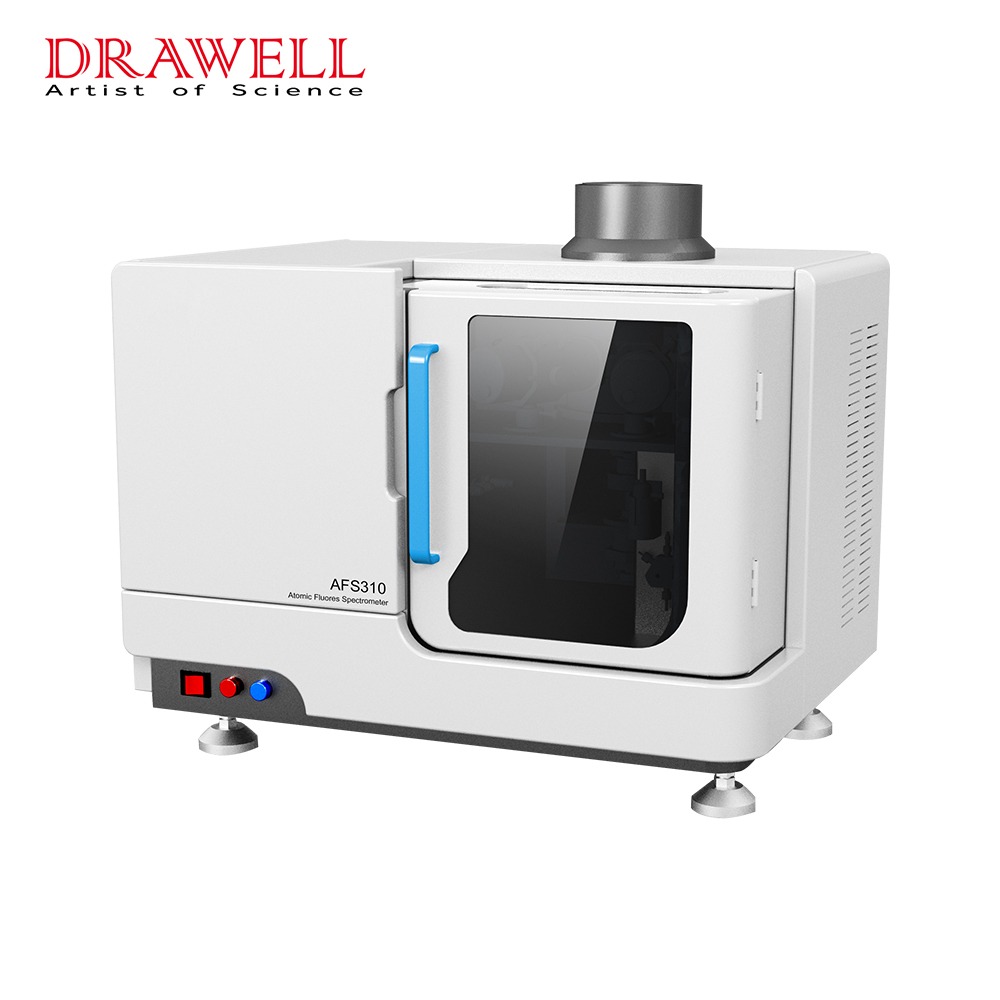

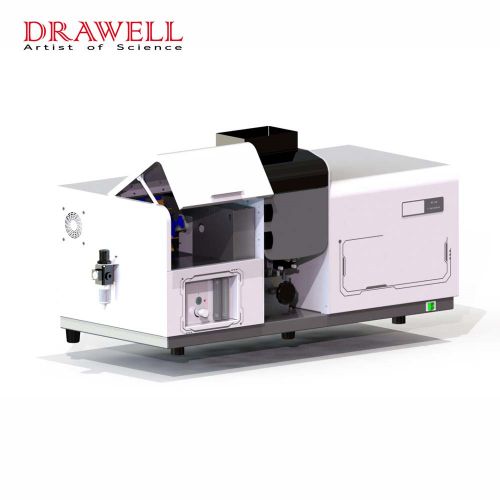

Optical path system of AAS

1. Is the position of the hollow cathode lamp the best?

The hollow cathode lamp can radiate the resonance line of the element to be measured and has sufficient radiation intensity to ensure a sufficient signal-to-noise ratio.

If the position of the hollow cathode lamp deviates, the light energy will be lost in the light path.

The light signal entering the detector will be correspondingly weakened, and the measurement sensitivity of the instrument will be reduced.

Therefore, after each lamp change, the position of the lamp holder should be adjusted to maximize the energy indication of the instrument.

2. Is the most sensitive spectral line selected?

A hollow cathode lamp of an element often has many emission lines.

The most sensitive spectral line should be selected for measurement.

Some resonance spectral lines are relatively close to each other. For example, the manganese lamp has a spectral line at 279.5nm, 279.8nm, and 280.1nm, and the spectral line at 279.5nm is the most sensitive.

If there is a certain error in the wavelength indication of the instrument, it is easy to be confused if it is not carefully distinguished.

3. Is the lamp’s current setting appropriate?

The light intensity of a hollow cathode lamp is related to the lamp current.

Increasing the working current of the lamp can increase the emission intensity.

However, if the working current is too high, the discharge will be abnormal and the light intensity will be unstable.

If the lamp current is too low, the light intensity of the lamp will be weakened, resulting in a decrease in stability and signal-to-noise ratio.

Therefore, it is important to select an appropriate lamp.

The optimum lamp current varies with cathode elements and lamp design.

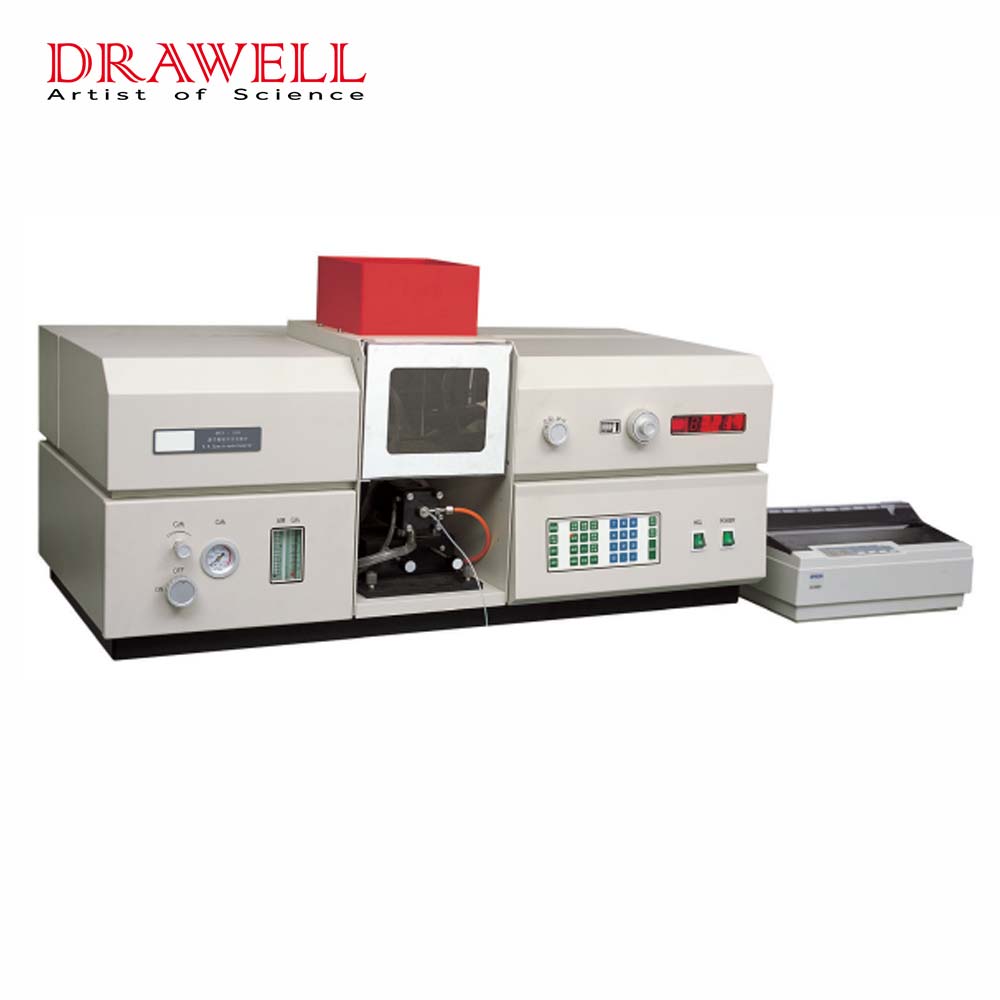

AAS atomization system

1. Whether the injection capillary is blocked

The function of the capillary is to aspirate the sample solution.

If the injection capillary is clogged with contamination, the injection speed will be greatly reduced and a strong signal will not be generated.

It must be dredged with a fine wire, or replaced with a new capillary.

2. Is the pressure of the compressed air too low?

Compressed air not only participates in combustion as auxiliary gas but also generates negative pressure at the capillary mouth to absorb the sample solution.

The drop in the pressure of the compressed air will cause insufficient negative pressure at the capillary suction port and slow down the sample suction speed.

To this end, check whether the output pressure of the air compressor is too low, whether there is air leakage in the air pipeline, and whether the airflow setting is too small.

3. Whether there is a water seal in the waste liquid pipe

If there is no water seal in the waste liquid pipe or the water seal is not tight, the liquid discharge pipe will be connected to the outside atmosphere, the negative pressure in the atomization chamber will be reduced, and the sample suction speed will also be slowed down, or even no sample will be suctioned.

4. Whether the burner has too many solid pollutants

After the burner has been used for some time, it will pick up some solids, including some carbon deposits and inorganic salts in the solution.

The existence of these substances will seriously affect the properties of the flame, such as zigzag flame, unstable flame, uneven flame, and so on.

At the same time, it will increase the signal noise, resulting in unstable measurement results.

Therefore, it needs to be cleaned in time.

Combination of optical path system and atomization system

The generation of luminosity is caused by the absorption of the characteristic spectral lines emitted by the light source by the ground state atoms.

The greater the number of ground state atoms, the greater the absorbance.

When the light source line passes through the burner, the light source line should be completely and parallelly passed through the flame, that is, the atomized layer, to generate a strong enough absorption signal, and the measurement sensitivity will be high. Therefore check and adjust the height and orientation of the burner.