Sulfur is a common element that has significant implications for diverse industries. The sulfur analysis plays an important function in a variety of industries, such as petroleum, environmental monitoring and agricultural. The accurate determination of the amount of sulfur in a product is essential for ensuring the quality of products, ensuring compliance with regulations as well as minimizing environmental impacts. However, the traditional sulfur analysis techniques typically require long-running processes and extensive resource allocation. This article examines the most modern and efficient methods of sulfur analysis which save time and money while ensuring precision and accuracy.

Why Use a Sulfur Analyzer?

The analysis of sulfur is a crucial element in numerous environmental and industrial applications. Sulfur content in the materials impacts everything from the quality of products to compliance with regulatory requirements. For example:

- Oil and Fuels: In excess, sulfur in fuels can cause the pollution of the air and also to corrosion in engines, which makes sulfur control a necessity to meet the environmental requirements.

- Fertilizers: Sulfur plays crucial roles in the nutrition of plants. An accurate analysis can ensure the proper amount of sulfur for the best yield in the crop.

- Environment Monitoring: Sulfur compounds like SO2, are major pollutants that require surveillance. The measurement of sulfur oxides as well as sulfates are essential for evaluating the water and air quality as well as knowing the effects from acid rain.

Thus, a timely and accurate sulfur analysis is essential to help companies to meet the strictest standards for quality and regulations and ensure that equipment is protected from damage and help sustain the environment by reducing emissions.

The Bottlenecks of Traditional Sulfur Analysis

Although there are a variety of traditional methods to analyze sulfur, these methods typically are prone to shortcomings in terms of efficacy.

Methods that use wet chemicals like gravimetric determination of sulfate and titrimetric techniques can be time-consuming and require numerous manual steps, lengthy reactions, and a significant use of reagents. The traditional combustion analysis, although efficient, can require a complex sampling and prolonged analysis cycles. These tedious processes can not only slow the overall workflow but also add to the cost of analysis because of the increased amount of labor required, energy consumed and waste generation. The potential for mistakes in the multi-step process also affects the reliability and repeatability of the results.

Thus, the necessity for quicker, more automated and efficient alternatives is increasingly evident across industries that are trying to improve their analysis processes.

Modern and Efficient Sulfur Analysis Methods

The field of analysis for sulfur is being transformed through technological advances, leading to the development of superior methods. Modern methods rely on advanced instruments, efficient sampling, automated and advanced data processing to surpass the limitations of traditional methods which can result in significant savings in time and funds.

1. Advancements in Instrumentation:

The advancement in sulfur analyses has been driven by the remarkable advances in the field of analytical instruments. These cutting-edge techniques have gone past the limits of conventional methods, and offer unimaginable speeds effectiveness, sensitivity, and speed. Here are a few key instruments which have revolutionized sulfur analysis:

| Technique | Key Features | Primary Advantages | Typical Industry Applications |

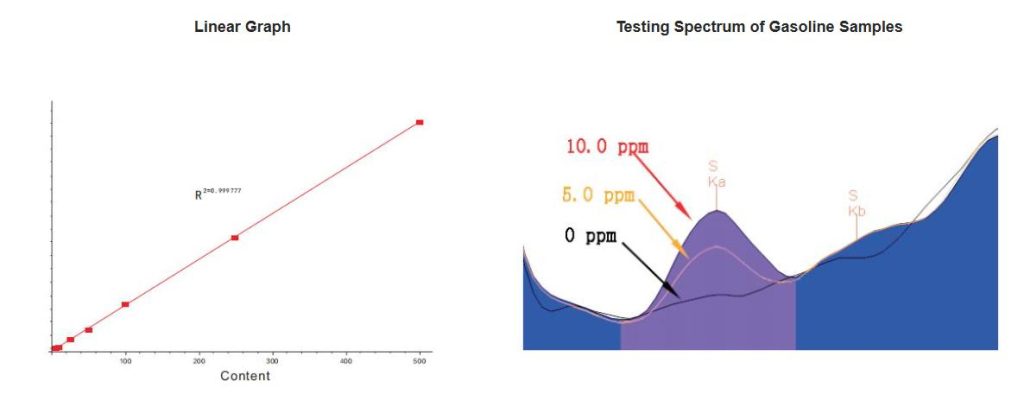

| Energy Dispersive X-ray Fluorescence (ED-XRF) | It measures the X-ray energy emitted Easy setup; Portable options are available. | Rapid analysis; minimal preparation of the sample; usually non-destructive, suitable for use on-site. | Petroleum (fuel sulfur content) as well as environmental (soil and water screening) Materials science (composition) and mining (ore evaluation). |

| Wavelength Dispersive X-ray Fluorescence (WD-XRF) | Differentiates X-rays according to wavelength. higher spectral resolution and the sensitivity. | Precision and accuracy; Ideal for complex matrices with less concentrations. High throughput when using the use of automation. | Petroleum (refined products) and Environmental (soil sediment analysis, soil) Mining; Cement; Metals. |

| Inductively Coupled Plasma OES/MS (ICP-OES/MS) | Introduction of liquid samples to plasma. the emission of the light (OES) or Ions (MS). | Accuracy and sensitivity Ability to analyze multi-elemental samples Good to analyze liquids. | Environment (water analysis) and Agriculture (fertilizers and plants,); Food & Beverage; Pharmaceuticals; Clinical chemistry. |

| Combustion Analysis with Advanced Detection | Samples are burned in oxygen. It detects sulfur oxides (e.g. through the IR as well as electrochemical). | Fast analysis cycle; minimal preparation of samples for matrices with many variables Automation of process. | Coal and Coke and Petroleum (crude oil and fuels) Material science (polymers) and Environmental (total sulfur content in solids). |

| Electrochemical Methods | Measures electrical changes at electrode-electrolyte interface. | Potential for cost-effective, rapid and portable analysis. Specific for particular sulfur species. | Environment (H2S monitoring in air and wastewater) Process monitoring in industrial settings and emerging applications for broader analysis of sulfur. |

| Automated Spectrophotometric Methods Using Automation | Determines the light absorption of colored sulfur compounds. | High throughput using automated systems (FIA microplate readers) Reducing reagent use Also, relatively low cost. | Environment (sulfate present in the water); Food & Beverage (sulfites) Analyzing chemical. |

In conclusion, the world of analysis for sulfur is being transformed through these advanced instrumental methods. Each technique has its own combination of strengths and capabilities provides a viable way to break through the bottlenecks of traditional methods. The choice of the right instrument is based on the particular requirements of the analytical.

2. Optimized Sample Preparation Techniques:

Effective sulfur analysis isn’t entirely dependent on the latest instruments; optimized sample preparation plays a vital function in reducing the amount of time and resources used.

Traditional steps in the preparation of samples that require long digestion processes or lengthy cleaning processes, could be significant bottlenecks. Modern techniques focus on reducing these steps or implementing faster and more efficient methods:

- Direct analysis methods, in which the sample is analysed without any preparation (as is the case in certain applications using ED-XRFs) They are great for reducing time and energy.

- Microwave digestion provides a major improvement over conventional heating techniques for sampling digestion dramatically cutting down on digestion time and frequently needing smaller amounts of Reagents.

- SPE (SPE) as well as microextraction methods allow for the selective removal and the concentration of sulfur compounds. They also reduce matrix effects as well as the need for extensive cleaning procedures which streamlines the overall process of analysis.

The choice of the right method of preparation for the sample is essential to maximize the effectiveness of the selected sulfur analysis technique.

3. The Role of Automation and High-Throughput Systems:

Automation is an essential element of a more efficient sulfur analysis especially in laboratories that handle large quantities of samples.

Automated sampling systems that include robotic arms and autosamplers are able to load, process and unload samples with no any manual intervention, thereby increasing the speed of processing and minimizing the chance of human mistakes. Analytical platforms integrated that integrate several steps, like automated sample preparation, followed with analysis simplify processes and reduce time to complete. Advanced-throughput platforms that often incorporate analyzers with multiple channels or processors that can be parallelized, enable simultaneous analysis of several samples which significantly increases the amount possible analyses carried out within a specific time.

Automation will not only reduce the cost of labor and cuts down on time for analysis but also increases the repeatability and reliability of the findings.

4. Data Analysis and Reporting Efficiency:

The efficacy of the complete sulfur analysis process goes beyond the laboratory bench, to data analysis and report generation.

Modern analytical tools are generally equipped with sophisticated software that automatizes data acquisition, processing and analysis. This reduces the requirement to manually enter data and calculations, thereby reducing the chance of errors and also reducing time. Software applications typically have tools that automatize calibration as well as quality control checks and reporting, which can further streamline the procedure. Data acquisition in real-time allows analysts to keep track of the progress of their analysis and pinpoint any issues quickly.

Data management systems that are efficient facilitate the storage, retrieval and sharing of laboratory results which improves the overall efficiency of laboratories and speedier diffusion of important information.

Considerations for Implementing Efficient Methods

Implementing an effective sulfur analysis process requires careful consideration of multiple aspects to ensure the strategy is compatible with operational requirements as well as industry standards and resources limitations. Here are the most important considerations to help guide the process of making a decision:

1. Understanding the Sample Type

The chemical and physical properties of the sample greatly influence the selection of an analysis method.

- Solid Samples: Methods such as burning analysis, and the XRF are ideal for the analysis of solids, such as coal mineral, polymers, and minerals.

- Liquid Samples: ICP-OES, ICPMS and spectrophotometric methods are frequently used for oil, fuel or chemical solutions because of their sensitivity and accuracy.

- Gaz Samples: Electrochemical sensors and gas chromatography (GC) methods are excellent at the detection of sulfur compound in the gaseous matrixes.

Each type of sample needs a specific preparation steps, instruments and calibration procedures to ensure precision.

2. Accuracy and Sensitivity Requirements

The level of precision required is contingent on the particular use and the regulatory standards.

- High-Sensitivity Application: The detection of trace levels of sulfur in diesel or pharmaceuticals requires advanced techniques such as ICP-MS or WD-XRF.

- Routine Analysis: for routine quality control that has moderate accuracy requirements, techniques such as EDXRF or automated spectrophotometry offer the perfect balance of effectiveness and dependability.

The assessment of accuracy requirements ensures the compliance of industry standards without requiring excessive investment in advanced technology.

3. Operational Efficiency and Throughput

The latest sulfur analyzers differ in their capacity to handle huge sample volumes with ease.

Laboratories that handle large volumes profit from automation and high-throughput equipment that reduce the need for manual work and improve productivity.

Low-throughput facilities can be a good choice for the most cost-effective standalone instruments that have user-friendly interfaces.

An understanding of the lab’s work will help determine the best proportion between speed, cost and the complexity of operations.

4. Cost Considerations

The financial implications of using the sulfur analysis method is ongoing and upfront costs:

- Initial Costs: Purchase of an instrument installation, as well as instruction for operators.

- Operating Costs: Consumables, maintenance, calibration, as well as the use of energy.

- Long-Term Savings: Strategies that incorporate automation and high throughput could lower labor costs and increase efficiency of the resource over time.

An analysis of the cost-benefit ratio can uncover hidden savings through decreasing the use of reagents and energy consumption as well as the amount of analysis time.

5. Regulatory Compliance and Quality Standards

Different industries have their own regulations that define acceptable limits for sulfur and analysis methods. Make sure that the method you choose is in compliance with all standards in force (e.g., ASTM, ISO as well as EPA guidelines).

Establish robust quality control procedures to ensure the repeatability and accuracy of results.

6. Scalability and Future Needs

In investing in sulfur analysis technology, you must be considered in light of possible shifts in operational scale or analysis needs. Make sure to select systems that are able to adjust to changing demands for example, the increased capacity of samples or the introduction of new thresholds for regulatory compliance. Look into the possibility of upgrading or modularizing your instrument for maximum long-term use.

7. Operator Expertise and Training

The degree of difficulty associated with the selected method determines the degree of knowledge needed. The most advanced instruments will require technicians who are familiar with calibration and maintenance as well as troubleshooting. Software training programs and user-friendly interfaces will help ease the learning curve while ensuring an efficient and accurate operation. Get in touch with the manufacturer of the sulfur analyzer for more information on how to use the equipment.

9. Data Management and Integration

Modern instruments typically have integrated reporting and data processing features. Be sure to ensure that they are compatible with existing lab Information management software (LIMS). Find features such as real-time monitoring, automated logging and custom reporting that can simplify workflow and improve security of your data.

Through careful consideration of the sample type and type, requirements for regulatory compliance in addition to operational demands and long-term goals, companies can choose and apply methods of sulfur analysis that will maximize effectiveness and efficiency. An approach that is strategic will ensure that the system chosen is not just able to meet current requirements but also offers the flexibility to be able to respond to the challenges of the future.

Final Thoughts

A high-quality sulfur analysis is not more a luxury, but rather an essential requirement for companies and environmental monitoring agencies aiming to improve efficiency, effectiveness as well as sustainability. Advancements in the field of instrumentation, such as ED-XRF ICP-OES/MS and the latest combustion analyzers combined with optimized methods of preparation of samples and the integration of automation and high-throughput equipment, and simplified reports and analysis of data provide significant advantages over traditional methods. Modern methods dramatically cut down analysis time, save valuable resources like reagents, reagents, and energy, reduce the amount of waste generated, and increase the accuracy of sulfur determination. When you carefully consider the needs of the application and investing in the most efficient technology laboratories can realize substantial time and cost savings which will ultimately lead to better efficiency and a lower environmental footprint.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.