A carbon and sulfur analyzer is a device used to measure the content of carbon and sulfur in materials. Carbon and sulfur are important elements in many materials, such as steel, iron, petroleum, cement, food, and environmental samples. Measuring carbon and sulfur content is important for quality control, process optimization, and environmental compliance.

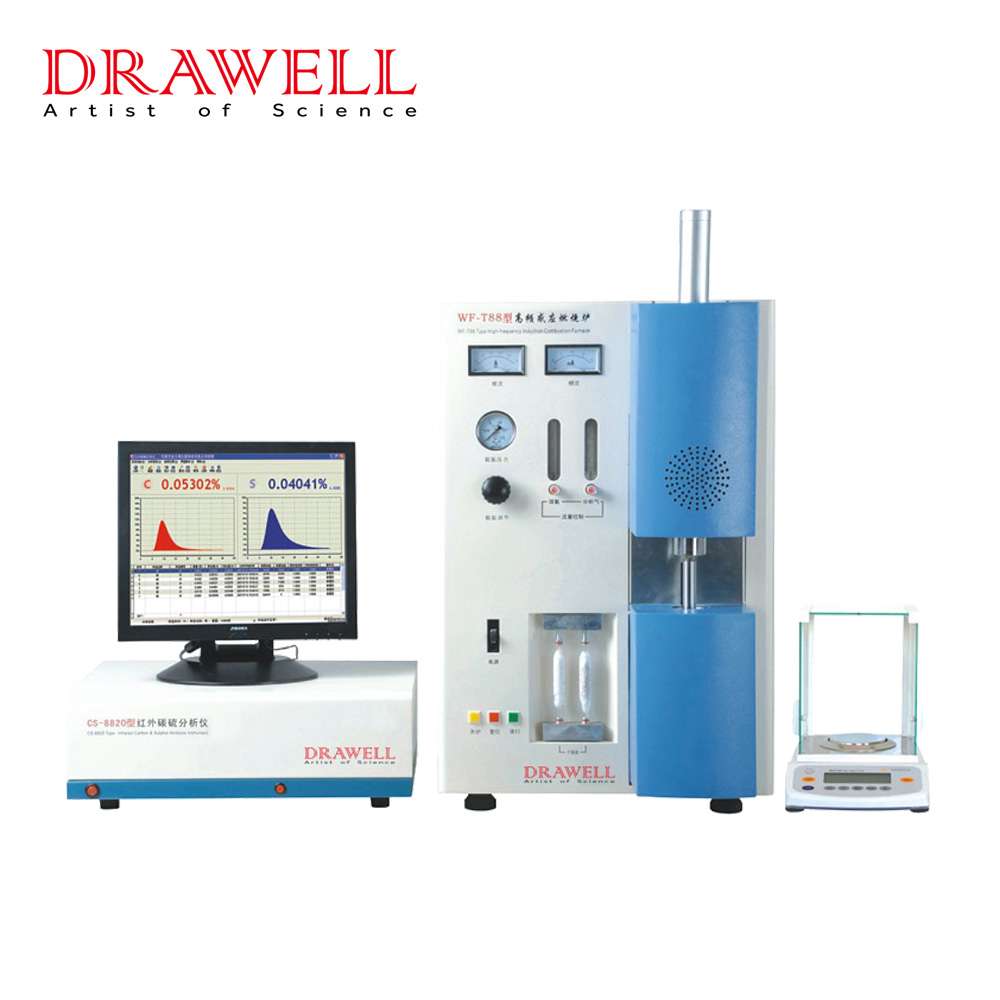

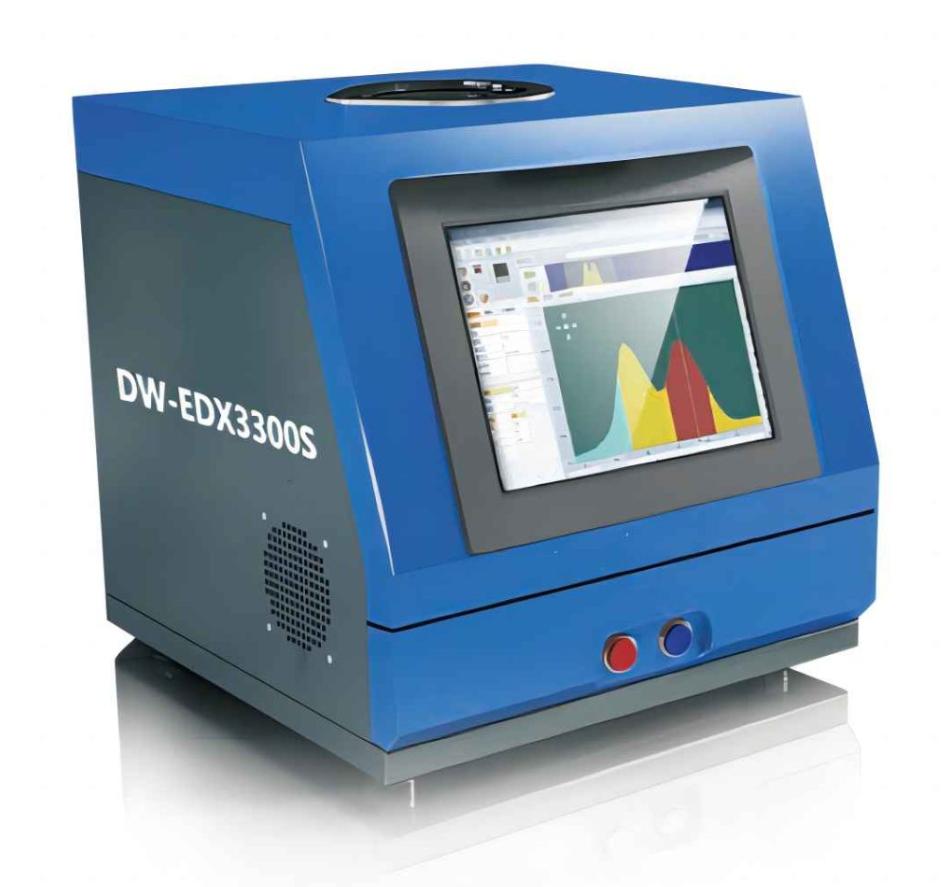

There are two main types of carbon and sulfur analyzers: elemental analyzers and combustion analyzers. Elemental analyzers use a variety of techniques to measure the elemental composition of a sample, including carbon and sulfur. Combustion analyzers burn the sample in an oxygen atmosphere to convert carbon and sulfur to carbon dioxide and sulfur dioxide, respectively. The carbon dioxide and sulfur dioxide are then detected and quantified.

This article will focus on the principle of operation of combustion carbon and sulfur analyzers.

Carbon and Sulfur Analyzer Principle of operation

The principle of operation of a combustion carbon and sulfur analyzer is to combust the sample in an oxygen atmosphere and then separate and detect the carbon dioxide and sulfur dioxide that is produced.

Combustion of the Sample

The sample is weighed and placed in a combustion crucible. The crucible is then placed in a combustion furnace, which is heated to a high temperature (typically 1200-1600 °C). The oxygen atmosphere in the furnace causes the sample to combust, converting carbon and sulfur to carbon dioxide and sulfur dioxide, respectively.

The combustion gases pass through a series of traps and filters to remove moisture and other impurities. The carbon dioxide and sulfur dioxide are then separated and detected using a variety of methods, including:

- Infrared absorption: Carbon dioxide and sulfur dioxide absorb infrared radiation at specific wavelengths. By measuring the amount of infrared radiation absorbed by the sample, the concentration of carbon dioxide and sulfur dioxide can be determined.

- Gas chromatography: Gas chromatography is a technique used to separate and quantify different components in a mixture. The combustion gases are passed through a chromatographic column, which separates the carbon dioxide and sulfur dioxide from other components. The carbon dioxide and sulfur dioxide are then detected using a variety of detectors, such as a flame ionization detector or a thermal conductivity detector.

- Volumetric analysis: Volumetric analysis is a technique used to quantify the concentration of a substance in a solution. The combustion gases are bubbled through a solution that absorbs the carbon dioxide and sulfur dioxide. The amount of carbon dioxide and sulfur dioxide absorbed is then determined by volumetric analysis.

Measurement Methods of Carbon and Sulfur Analyzers

The most common measurement methods for carbon and sulfur analyzers are infrared absorption and gas chromatography. Infrared absorption is a relatively simple and inexpensive method, but it is not as sensitive as gas chromatography. Gas chromatography is a more sensitive method, but it is also more complex and expensive.

Infrared absorption

Infrared absorption is a technique that measures the amount of infrared radiation that is absorbed by a sample. Carbon dioxide and sulfur dioxide absorb infrared radiation at specific wavelengths. By measuring the amount of infrared radiation absorbed by the sample at these wavelengths, the concentration of carbon dioxide and sulfur dioxide can be determined.

Infrared absorption is a relatively simple and inexpensive method, but it is not as sensitive as gas chromatography. This is because other components in the combustion gases can also absorb infrared radiation, which can interfere with the measurement.

Gas chromatography

Gas chromatography is a technique that separates and quantifies different components in a mixture. The combustion gases are passed through a chromatographic column, which separates the carbon dioxide and sulfur dioxide from other components. The carbon dioxide and sulfur dioxide are then detected using a variety of detectors, such as a flame ionization detector or a thermal conductivity detector.

Gas chromatography is a more sensitive method than infrared absorption, but it is also more complex and expensive. This is because the chromatographic column and detector must be carefully calibrated to ensure accurate results.

Volumetric analysis

Volumetric analysis is a technique that quantifies the concentration of a substance in a solution. The combustion gases are bubbled through a solution that absorbs the carbon dioxide and sulfur dioxide. The amount of carbon dioxide and sulfur dioxide absorbed is then determined by volumetric analysis.

Volumetric analysis is a relatively simple and inexpensive method, but it is not as sensitive as infrared absorption or gas chromatography. This is because the solution must be carefully prepared and the measurement must be performed accurately.

Advantages and Disadvantages of Different Measurement Methods

The following table summarizes the advantages and disadvantages of different measurement methods for carbon and sulfur analyzers:

| Measurement method | Advantages | Disadvantages |

| Infrared absorption | Simple, inexpensive, and easy to use | Not as sensitive as gas chromatography |

| Gas chromatography | More sensitive than infrared absorption | More complex and expensive than infrared absorption |

| Volumetric analysis | Relatively simple and inexpensive | Not as sensitive as infrared absorption or gas chromatography |

Applications of Carbon and Sulfur Analyzers

Carbon and sulfur analyzers are used in a wide variety of industries, including:

- Steel and iron production: To measure carbon and sulfur content in steel and iron alloys. Carbon and sulfur are important elements in steel and iron alloys, and their content must be carefully controlled to achieve the desired properties.

- Petroleum refining: To measure carbon and sulfur content in crude oil and refined petroleum products. Carbon and sulfur can cause corrosion and other problems in petroleum refining equipment, so their content must be monitored and controlled.

- Cement production: To measure carbon and sulfur content in cement raw materials and finished products. Carbon and sulfur can affect the quality and performance of cement, so their content must be controlled.

- Food analysis: To measure carbon and sulfur content in food products. Carbon and sulfur can be used to determine the nutritional content of food products and to detect adulteration.

- Environmental monitoring: To measure carbon and sulfur content in air, water, and soil samples. Carbon and sulfur can be pollutants, so their content must be monitored to ensure environmental compliance.

Calibration and Maintenance of Carbon and Sulfur Analyzers

Carbon and sulfur analyzers must be calibrated and maintained regularly to ensure accurate results. The calibration procedure varies depending on the type of analyzer, but it typically involves running a series of standards with known carbon and sulfur content. The analyzer is then adjusted so that it reads the correct concentration of carbon and sulfur in the standards.

The maintenance schedule for a carbon and sulfur analyzer also varies depending on the type of analyzer, but it typically includes cleaning the combustion chamber and furnace, replacing filters, and checking the calibration.

Conclusion

Carbon and sulfur analyzers are essential tools for quality control, process optimization, and environmental compliance in a wide variety of industries. By understanding the principle of operation of carbon and sulfur analyzers, users can select the right analyzer for their needs and obtain accurate and reliable results.