Features

- Adopting the double CPU design, electronic circuit integration degree is highly, steady and reliable, which can settle the high-frequency interference thoroughly.

- The special new platinum infrared light source, Gold plated carbon sulfur analysis pool and high precision pyroelectric infrared detector to make the apparatus’ measurement more accurate.

- Adopting the high power and quick frequency circuit design, which using 6KVA high frequency power tube(actual use of power is about 2.5KVA, it can turn on to work itself), to reduce the high frequency combustion system load and to increase the using time.

- Furnace head automatic cleaning device, patent technology supply system and -0.4mm amd hole metal filter to make the dust and gas seperated, reducing the dust on the result of analysis.

- Specialized analysis software of many different language owns following functions: curve/data storage, blank deduction, parameter determination, channel choosing, data statistics, results correction, breakpoint correction, curve comparison, system diagnosis, automatic/manual printing analysis results etc.

Application Fields

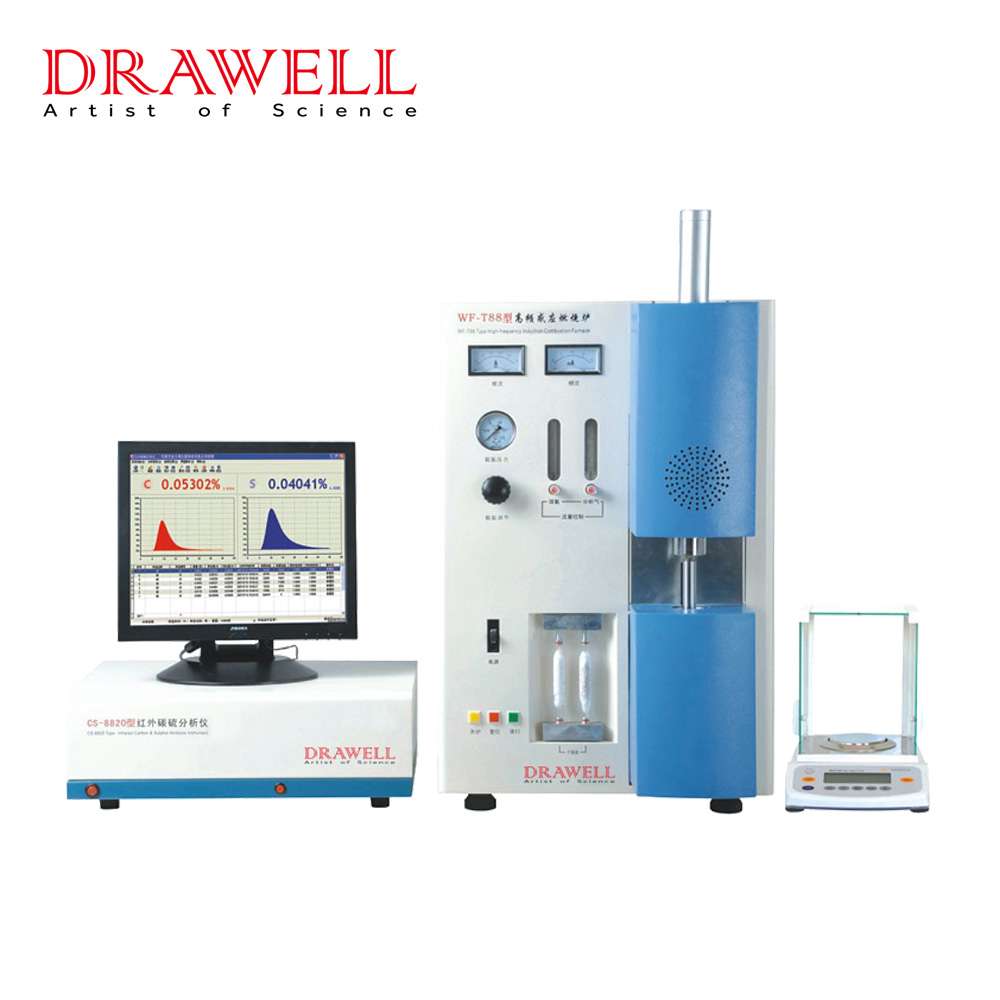

Infrared Carbon & Sulfur Analyzer, with infrared analysis techniques and arc burner, Testing the mass fraction of C, S of steel, iron, alloy, mold and cores, nonferrous metal, cement, ore, coke, catalyst, magnetic materials, ceramic, inorganic substance, black lead, refractory matter, battery matter, plant and other materials.

Main Technical Parameters

| Measuring range | C: 0.0001%-10.0000% (can extend to 99.9999%) |

| S: 0.0001%-3.5000% (can extend to 99.9999%) | |

| Analysis of error | With GB / T20123-2006/ ISO15350: 2000 standard |

| Analysis time | 25-60 seconds can be set ( usually 35 seconds) |

| High frequency furnace | power ≥2.7KVA Oscillation frequency:20MHz |

| Electronic balance | weight the sample in variable amount Accuracy of reading:0.0001g |

| Working environment | indoor temperature:10-30℃,relative humidity:<90% |

| Power supply | voltage:AC220V±5%,frequency:50Hz±2% |

| Oxygen | Purity: ≥99.5%, input pressure : 0.18MPa + 5% |

Spare Parts List

| Name | specification | Unit | Qty | Remarks |

| Pressure reducing valve | Piece | 1 | With a special connector | |

| Tungsten particle | Kg | 1 | ||

| Pure iron | Taigang C | bottle | 1 | |

| Quartz tube | Piece | 1 | With this machine | |

| Dust cleaning tube | Piece | 2 | ||

| Copper crucible supporting | Piece | 1 | ||

| Porcelain crucible supporting | Piece | 2 | With this machine | |

| Porcelain crucible | Carton | 1 | ||

| Stainless steel brush | Piece | 2 | ||

| Steel brush | Piece | 1 | ||

| Tweezers | Piece | 1 | ||

| Samples of spoon | Large, medium and small | Set | 1 | |

| Paint brush | Piece | 1 | ||

| Combination tool | Set | 1 | ||

| PVC tube | 4mm×6mm | Meter | 10 | |

| Silicone | Red | Piece | 1 | |

| O type Ring | 13mm×1.9mm | Piece | 2 | |

| O type Ring | 37mm×3.1mm | Piece | 2 | |

| Vacuum silicone | bottle | 1 | ||

| Fuse | 4A、20A | Piece | 2 | |

| Fast-plug connectors | PC06-01 | Piece | 2 | |

| Fast-plug connectors | PC06-02 | Piece | 2 | |

| Multi-purpose socket | 10A | Piece | 1 | |

| Chip | 2003 | Piece | 2 | |

| Chip | TLP521-4 | Piece | 2 | |

| Desiccant | 125g/ bottle | bottle | 1 | |

| Ash discharge tube | silica gel | Piece | 1 |