Vacuum drying ovens are indispensable tools in laboratories and industrial settings, offering efficient drying capabilities while minimizing the risk of damaging sensitive materials. When it comes to selecting the right vacuum drying oven for your specific needs, several crucial questions must be addressed to ensure optimal performance and safety. Whether you’re a seasoned researcher or just getting started with vacuum drying, understanding the key factors to consider will guide you in making an informed decision.

In this article, we’ll delve into the essential questions you should ask when choosing a vacuum drying oven, covering aspects such as size, temperature range, the level of vacuum required, and the types of materials suitable for drying.

1. What size of a vacuum drying oven do I need?

The size of the vacuum drying oven you need depends on your specific requirements and the volume of materials you plan to dry. Here are some factors to consider when determining the size of the vacuum drying oven:

- Sample volume: Consider the quantity of materials you need to dry in a single batch. If you have large samples or need to dry a significant volume of materials simultaneously, you will require a larger oven.

- Available space: Evaluate the space you have in your laboratory or work area. Make sure the vacuum drying oven you choose fits comfortably in the available space without obstructing other equipment or workstations.

- Sample size and shape: The size and shape of your samples will also play a role in selecting the appropriate oven size. Ensure that the oven’s chamber dimensions can accommodate your largest samples without crowding.

- Throughput and efficiency: If you have a high volume of samples that need frequent drying, you might consider a larger oven with faster processing capabilities to improve efficiency.

- Future needs: Think about potential changes in your workload or expansion of your research. Selecting a vacuum drying oven with some extra capacity may be beneficial if you anticipate an increase in the volume of materials you’ll need to dry in the future.

- Budget: Larger vacuum drying ovens typically come with higher costs. Evaluate your budget and balance it with your requirements to find the most suitable size for your needs.

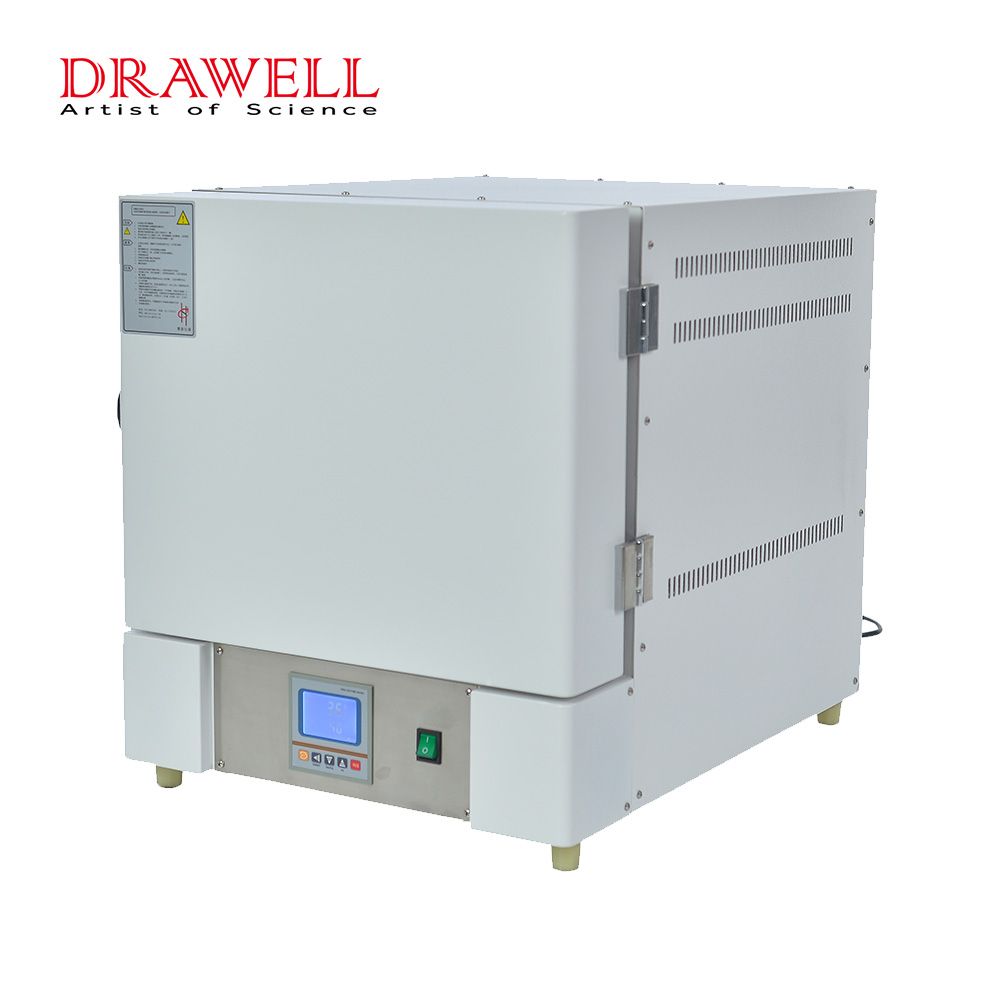

As a starting point, it’s essential to list down the typical sizes and quantities of samples you’ll be working with. Then, consult with laboratory equipment suppliers or manufacturers to discuss your specific requirements and get their recommendations for an oven size that best suits your needs. Drawell as a professtional manufacturer of laboratory equipment and scientific instruments believe us will serve your needs.

2. What temperature range does a vacuum drying oven need to maintain?

The temperature range that a vacuum drying oven needs to maintain can vary depending on the specific application and the materials being dried. Generally, vacuum drying ovens have a temperature range that allows for precise control and adjustment to meet various drying needs. The typical temperature range of a vacuum drying oven is between ambient temperature (room temperature) and around 200 to 250 degrees Celsius (392 to 482 degrees Fahrenheit).

Here are some common temperature ranges you might encounter with vacuum drying ovens:

- Low-temperature range: Some vacuum drying ovens have the capability to operate at low temperatures, typically starting from room temperature (around 20°C or 68°F) and going up to 100°C (212°F). These ovens are used for drying heat-sensitive materials that may degrade at higher temperatures.

- Medium-temperature range: Many vacuum drying ovens have a medium-temperature range, which spans from around 100°C (212°F) to 150°C (302°F). This range covers a wide variety of materials and is commonly used for general drying applications.

- High-temperature range: Some vacuum drying ovens can achieve higher temperatures, ranging from 150°C (302°F) up to 200°C (392°F) or even higher. These ovens are suitable for drying materials that require elevated temperatures to achieve the desired results.

- Ultra-high-temperature range: Specialized vacuum drying ovens designed for specific industrial applications might have ultra-high-temperature capabilities, reaching temperatures as high as 250°C (482°F) or more.

It’s crucial to choose a vacuum drying oven with a temperature range that matches your specific drying requirements. Ensure that the oven’s temperature control is accurate and reliable, especially if you’re working with temperature-sensitive materials or need precise temperature regulation for your experiments or processes. Always follow the manufacturer’s guidelines and recommendations for operating the vacuum drying oven within its specified temperature range to ensure safety and proper performance.

3. What level of vacuum does a vacuum drying oven need to achieve?

The level of vacuum that a vacuum-drying oven needs to achieve depends on the specific requirements of the materials being dried and the drying process. As mentioned earlier, vacuum drying ovens can have different vacuum pressure ranges, typically measured in millibars (mbar) or torr. The appropriate level of vacuum will depend on factors such as the boiling points of the solvents or moisture content in the materials.

In many laboratory and industrial applications, vacuum drying ovens can achieve vacuum pressures in the range of:

- Low vacuum: 200 to 400 millibars (mbar) or 150 to 300 torr.

- Medium vacuum: 10 to 100 millibars (mbar) or 10 to 75 torr.

- High vacuum: 0.1 to 10 millibars (mbar) or 0.1 to 7.5 torr.

The specific vacuum pressure required will vary based on the materials being dried and the desired drying conditions. For instance, if you are working with heat-sensitive or volatile materials, a higher vacuum level may be necessary to minimize the risk of degradation or loss of volatile compounds. On the other hand, some materials may require a lower vacuum level to achieve efficient drying without causing damage.

When selecting a vacuum drying oven, it’s essential to consider the vapor pressure of the substances you are drying and choose an oven that can reach the required vacuum level for your particular application. Manufacturers typically provide information on the vacuum pressure capabilities of their ovens, allowing you to make an informed choice based on your specific needs.

4. What type of material can I dry in a vacuum drying oven?

Vacuum drying ovens are versatile pieces of equipment that can be used to dry a wide range of materials across various industries. The ability to control temperature and reduce pressure inside the oven makes it suitable for drying heat-sensitive, delicate, or volatile substances. Here are some common types of materials that can be dried in a vacuum drying oven:

- Heat-sensitive materials: Vacuum drying ovens are excellent for drying heat-sensitive materials that might degrade or lose their properties at higher temperatures. These materials include certain pharmaceuticals, chemicals, and biological samples.

- Organic solvents: Many organic solvents have relatively low boiling points, and drying them under atmospheric conditions may result in excessive loss or unwanted reactions. Vacuum drying ovens allow for gentle drying of these solvents at lower temperatures, preventing their evaporation.

- Pharmaceuticals and pharmaceutical intermediates: Many pharmaceutical products, especially those containing active pharmaceutical ingredients (APIs), can be dried using vacuum drying ovens to remove residual solvents and water content without compromising their integrity.

- Laboratory glassware: Drying glassware in a vacuum drying oven helps to eliminate water spots and ensure a completely dry surface, which is crucial for accurate measurements and precise experiments.

- Electronic components: Vacuum drying is commonly used to dry electronic components and circuits to remove moisture and prevent potential damage during further processing or assembly.

- Food products: In the food industry, vacuum drying ovens are used to dry fruits, vegetables, herbs, and other food items while preserving their color, flavor, and nutritional content.

- Chemicals and reagents: Vacuum drying is effective for drying various chemicals, reagents, and chemical mixtures used in laboratories and industrial processes.

- Polymers and plastics: Vacuum drying ovens are often utilized to dry polymers and plastics to remove moisture before processing or molding, which can help improve the quality of the final product.

- Catalysts and catalyst precursors: Drying catalysts and their precursors in a vacuum drying oven is a common practice to enhance their stability and catalytic activity.

It’s important to note that not all materials are suitable for vacuum drying, especially those that may react with reduced pressure or require specific drying conditions that cannot be achieved in a vacuum environment. Always verify the compatibility of the material with vacuum drying and follow recommended procedures to ensure safe and effective drying processes. Additionally, consider the specific requirements of your materials and consult the manufacturer’s guidelines to determine the most appropriate conditions for drying in a vacuum drying oven.

Conclusion

In conclusion, selecting the ideal vacuum drying oven involves careful consideration of various factors to match the specific requirements of your applications. From the size of the oven and its temperature range to the level of vacuum it can achieve, each aspect plays a critical role in determining its effectiveness and efficiency in drying different materials. Always prioritize safety by adhering to the manufacturer’s guidelines, ensuring proper maintenance, and wearing appropriate protective gear. By addressing the essential questions highlighted in this article, you can confidently make a well-informed choice and invest in a vacuum drying oven that will meet your research or industrial drying needs, yielding reliable and precise results.