1400°C Chamber Muffle Furnace STM-14

- Integrated Structure with elegant design.

- Chamber Materials: Vacuum-forming ceramic fiber, which has the advantage of no powder drops off at high temperature, and saving energy more than 50%.

- SHIMADEN (Japan) Microprocessor-based self-tuning PID control provides optimum thermal

- Long life type S thermocouple.

- CE compliant.

- Built-in RS485 port and USB adaptor as optional settings for computer control. It needs to add extra fees.

Features

Specifications

| Model | STM-3-14 | STM-8-14 | STM-12-14 | STM-18-14 | STM-27-14 | STM-36-14 | OEM |

| Inner Dimmensin (WxDxH)mm | 150x150x150 | 200x200x200 | 200x300x200 | 250x300x250 | 300*300*300 | 300x400x300 | Any size |

| Outer Dimension (WxDxH)mm | 490x530x750 | 575x580x825 | 590x680x835 | 610x700x860 | 650*670*900 | 650x770x900 | |

| Type | Benchtop | ||||||

| Furnace structure | Alumina Ceramic Chamber, Temperature control system, Heating element, Furnace shell, Main Electric Parts and other relative accessories | ||||||

| Max temperature | 1400℃ | ||||||

| Continue Temp. | 1300℃ | ||||||

| Power supply | 220V/3KW | 220V/5KW | 220V/5KW | 220V/6KW | 380V/9KW | 380V/12KW | |

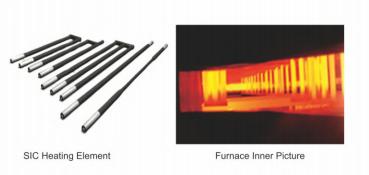

| Heating element | High quality Silicon Carbide Rod ( SIC) heater | ||||||

| Chamber material | High temperature 1500 Type polycrystal alumina ceramic fiber material | ||||||

| Temp precision | ±1℃ | ||||||

| Thermocouple | S type | ||||||

| Temp controller | SHIMADEN (Japan) brand intelligent microcomputer PID controller can program 4 groups 32 segments | ||||||

| Electronic Parts | SCHNAIDER (France ) electronics brand | ||||||

| Heating rate | ≤ 25℃/min ( suggest 15℃/min for longer life using of furnace ) | ||||||

| Safety protection | Overheat and thermocouple-break alarm | ||||||

| Certification | ISO9001 CE SGS | ||||||

| Furnace shell | High quality cold-rolled steel sheets CNC processing | ||||||

| Insulation | High quality thermal insulation material to ensure a good uniformity | ||||||

| Accessories | One pair of high temperature gloves , One pair of crucible tong , one catalog and operation manual | ||||||

| Optional | Paperless recorder , Stainless steel exhaust chimney , Quartz /Alumina crucible | ||||||