As a high-temperature heating instrument, muffle furnace is widely used in the lab. It will cause great harm if the muffle furnace is used improperly. The right using methods and precautions will protect yourself and others. This article will give you a few quick tips for muffle furnaces.

Structure of Muffle Furnace

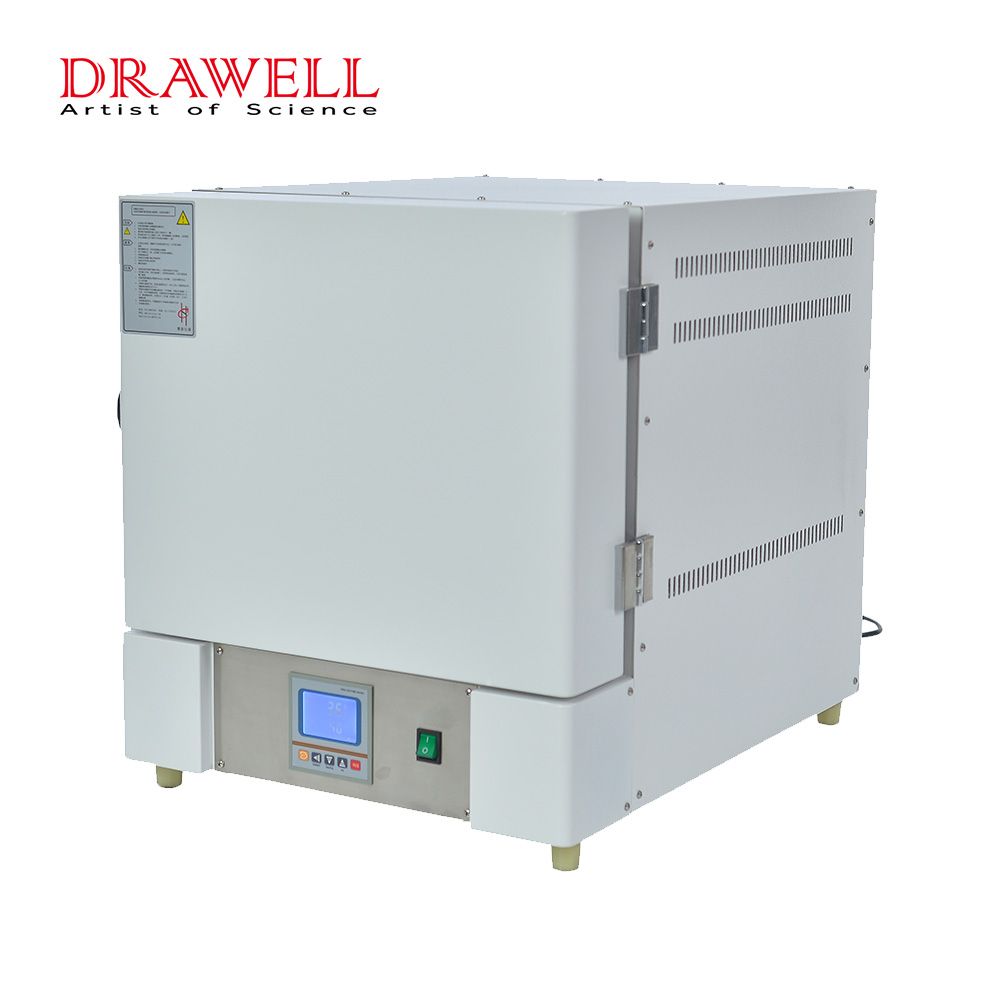

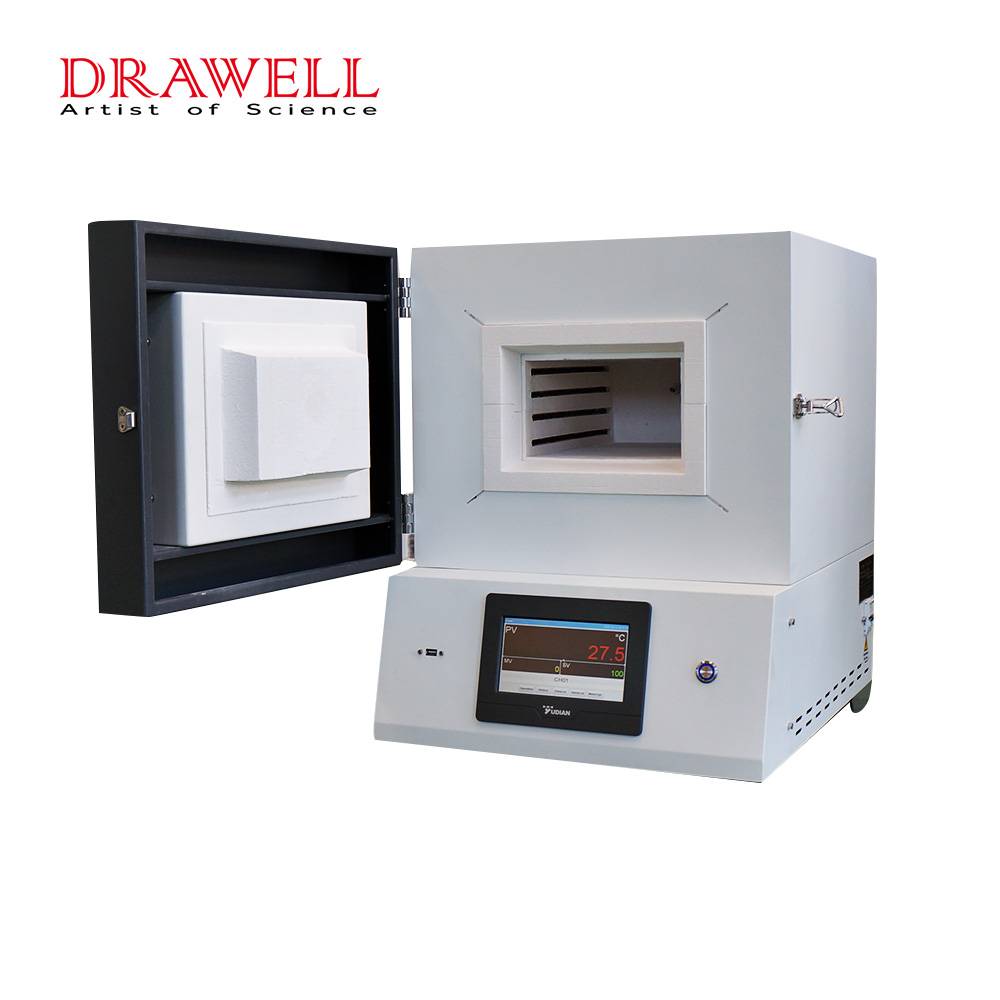

Muffle furnaces are the box shape. The products are fixed during the whole heating process of heating, heat preservation, and cooling, and the feeding and discharging are carried out through a single door or slot, with simple operation and convenient maintenance.

The furnace is made of stainless steel plate, surrounded by a heating and hot air circulation chamber, the hot air flows in the furnace, greatly improving the temperature uniformity.

The furnace chamber and furnace frame are designed separately. The furnace chamber is placed on the load-bearing roller at the bottom of the furnace frame and can slide freely in front and back. When the furnace is heated, it can extend freely along the length direction.

In order to prevent the leakage of hot gas in the furnace, a total of 2 layers of seals are designed at the furnace door from inside to outside. The inner layer is sealed with ceramic fiber rope, and the outer layer is sealed with a silicone rubber sealing ring. In order to extend its service life, a stainless steel cooling water jacket is designed at the furnace mouth seal for cooling. The door lock adopts a multi-point handwheel rotation locking mechanism, which can lock evenly around the door at the same time. In addition, the furnace door fixing device is installed on the end face of the furnace chamber and adopts a movable double-hinge mechanism, which can move with the free extension of the furnace and the sealing effect is better.

How to Use the Muffle Furnace

(1) After opening the package, check whether the muffle furnace is intact and whether the accessories are complete. The general muffle furnace does not need special installation but only needs to be laid flat on the flat floor or shelf in the room. The controller should avoid vibration and should not be placed too close to the electric furnace to prevent the internal components from working normally due to overheating.

(2) A thermocouple is inserted into the furnace for 20-50mm, and the gap between the hole and the thermocouple is filled with asbestos rope. It is better to use a compensation wire to connect the thermocouple to the controller. Pay attention to the positive and negative poles, and do not connect them in reverse.

(3) Additional power switch shall be installed at the inlet of the power line to control the main power supply. In order to ensure safe operation, the electric furnace and controller must be reliably grounded.

(4) Before use, adjust the thermometer indicator to zero point. When using the compensating wire and the cold end compensator, adjust the mechanical zero point to the reference temperature point of the cold end compensator. When the compensating wire is not used, adjust the mechanical zero point to the zero scales, but the indicated temperature is the temperature difference between the measuring point and the cold end of the thermocouple.

(5) After the wiring is checked and confirmed to be correct, cover the controller housing. Adjust the setting pointer of the temperature indicator to the required operating temperature, and then turn on the power. Turn on the power switch. At this time, the green light on the temperature indicator is on and the relay starts to work, the furnace is powered on, and the ammeter shows the current. With the increase of the internal temperature of the furnace, the pointer of the temperature indicator gradually rises, which indicates that the system works normally. The temperature rise and constant temperature of the furnace are respectively indicated by the traffic light of the temperature indicator, the green light indicating the temperature rise, and the red light indicating the constant temperature.

Precautions for Using of Muffle Furnace

(1) The muffle furnace must be placed on a stable cement platform, equipped with plugs, sockets, and fuses with appropriate power, and grounded to avoid danger.

(2) The working environment is required to be free of flammable substrates and free of explosive substances and corrosive gases. It is forbidden to bake liquid samples such as water and oil, and it is forbidden to directly pour various liquids and molten metals into the furnace, so as to keep the furnace clean.

(3) When in use, the furnace chamber temperature shall not exceed the maximum furnace temperature, nor shall it work for a long time under the rated temperature. During the test, the user shall not leave and pay attention to the temperature change at any time. In case of any abnormality, the power shall be cut off immediately and the professional maintenance personnel shall repair it.

(4) When using, the furnace door should be closed gently to prevent damage to the machine parts. The crucible clamp should be handled with care when taking samples to ensure safety and avoid damage to the furnace chamber.

(5) Do not open the furnace door when the temperature exceeds 600°C. Open the furnace door after the temperature in the furnace cooling naturally.

(6) After the experiment, the sample shall be removed from heating and the power supply should be turned off. When placing the sample in the lab muffle furnace, the furnace door shall be slightly opened, and the sample shall be carefully clamped after the sample is slightly cooled to prevent scalding.

(7) When the muffle furnace is not in use, cut off the power supply and close the furnace door to prevent the refractory from being eroded by moisture.