Any industry requires a variety of equipment to function properly. The Muffle Furnace is one such appliance that has a huge impact on enterprise functionality. To enable you to buy your favorite product in the shortest time, let us learn more about the purpose, type, and manufacturer of the horse boiler here.

What Is a Muffle Furnace?

Laboratory furnaces are excellent for heat therapy, response research studies, sintering processes, and the firing of porcelains. Our laboratory heating systems have temperatures of approximately 1600 ° C and also capacities of as much as 22 liters.

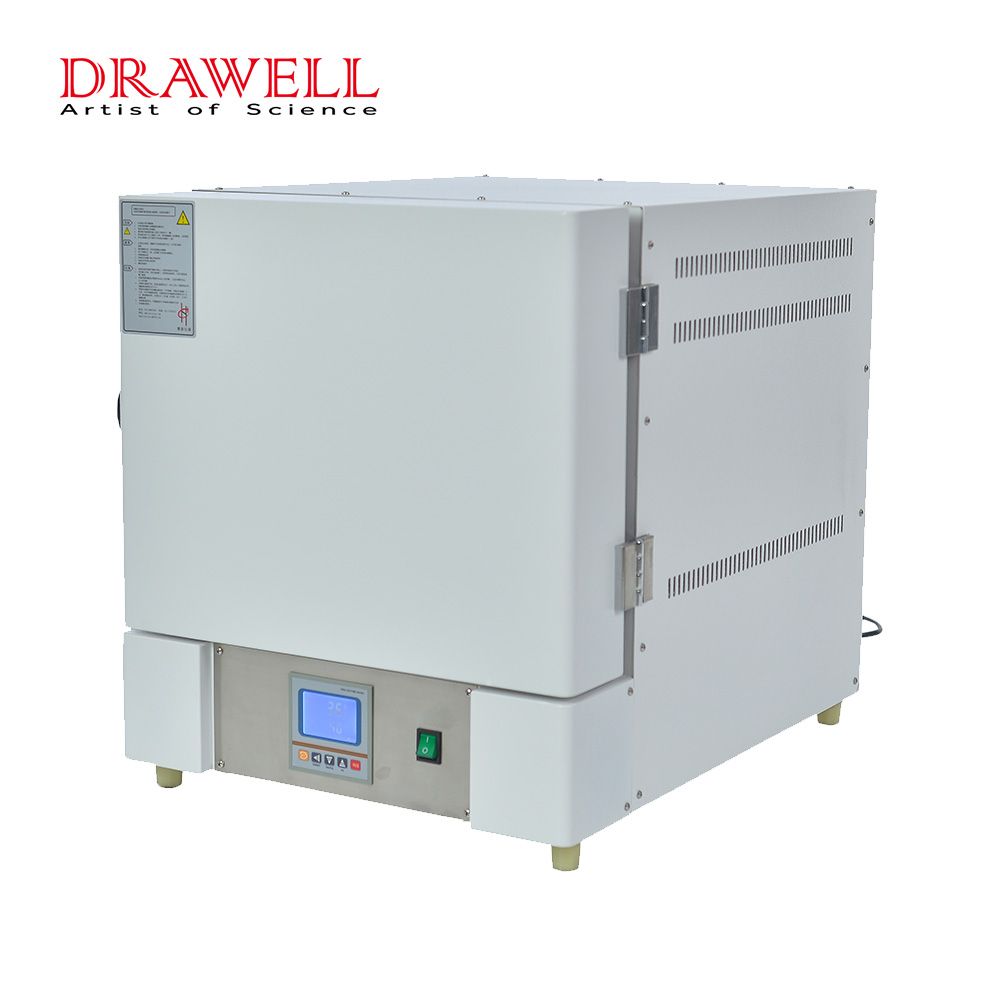

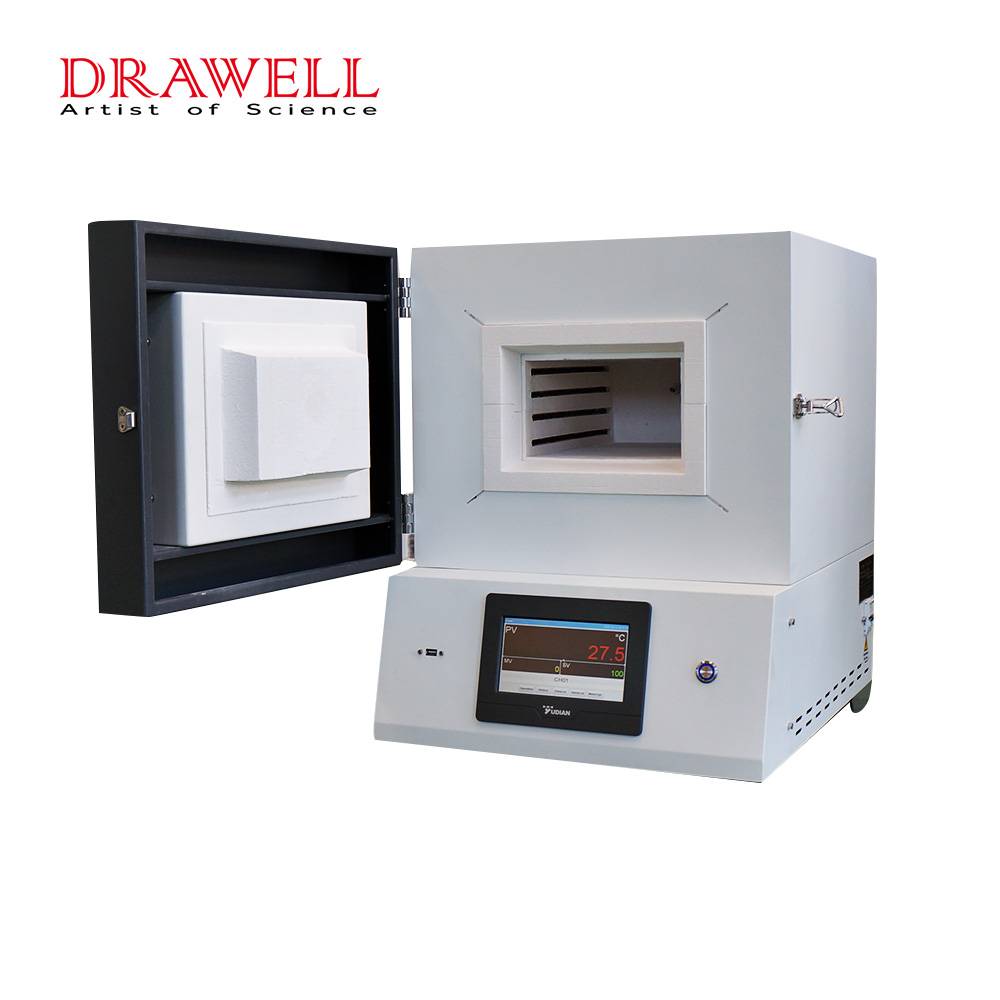

A muffle furnace is a lab heater. The muffle furnace isolates the example from the fuel as well as a combustion to remove contamination of the sample. They are durable, trustworthy, and function well for a wide range of uses Stifle furnaces are suitable for r & d, materials testing and quality control, warm treatment, porcelains, glass, and also extra.

A muffle furnace is a device that develops an environment ideal for processing products in heat. This process is handy in numerous areas such as glass-making or steelworking. It helps heat materials to heat while maintaining them in control and completely isolated from exterior impurities, chemicals, or compounds.

What Are the Usual Uses of the Muffle Furnace?

The ash web content of the samples is handy for testing in muffle furnaces, they aid examine numerous materials at high temperatures to recognize their ash content portion.

In a number of industries, these heating systems assist the procedure of different types of materials to determine the portion of ash under them.

Requirement anechoic furnaces are practical in the manufacture of glass, porcelains, and other products. In industries such as concrete production, factories, and the nuclear sector, muffle heating systems help process examples at high temperatures.

What is the function of the muffle furnace?

The ash web content of the examples is helpful for screening in muffle heating systems, they aid test numerous products at high temperatures to understand their ash material percent.

In several industries, these heaters aid the procedure of various types of materials to establish the percent of ash under them.

Criterion anechoic furnaces are helpful in the manufacture of glass, ceramics, and various other products. In industries such as cement manufacturing, shops, and also the nuclear industry, smother heating systems assist procedure samples at high temperatures.

What Are the Advantages of the Muffle Furnace?

Stifle heating systems are utilized to generate various metal items such as low-carbon steel, stainless steel, and copper.

The heaters in these heaters have an internal chamber for processing and also an outer covering where the product is placed.

They are made from heat-resistant products with high thermal conductivity, enabling them to maintain the desired temperature level inside the chamber.

A mix of radiative as well as convective heat transfer provides a uniform treatment of the workpiece.

Stifle heaters are suitable for the warm therapy of parts, assemblies, and also examples under high vacuum in numerous sectors.

They provide a uniform warmth circulation as well as can be utilized with various types of heating media: air, hydrogen, nitrogen, or their blends. Its durable layout allows for a long life span.

A lot of stifle heaters are reliable, low-priced, as well as easy to operate. It aids to satisfy a wide variety of testing requirements in electronics, auto engineering, as well as mechanical design.

It includes a structure designed to retain and also evenly distribute warmth in one location and is consequently used for warm therapy of material examples.

What Are the Heating Systems the Muffle Furnace Uses?

Prior to acquiring a muffle furnace for your office, you ought to have a quick take look at the different kinds of muffle heaters to select the right one for you:

1. Electric muffle furnace

An electric muffle furnace is a sort of valuable electric heater made used for creating, melting, drying, and also home heating materials.

They are similar to induction heating systems, yet as opposed to producing a magnetic field that heats the product placed inside, they make use of electrically heated refractory elements in a solid steel container.

They can run at greater temperature levels and also higher power thickness than induction heating systems.

2. Nabertherm muffle furnace

The Nabertherm muffle furnace is an application-oriented commercial furnace. These heaters are made used in a variety of industries, from steel and also other metal production to glass production, ceramics and also food processing, vehicle production, and aerospace.

3. Thermolyne muffle furnace

The Thermolyne muffle furnace is a unique type of industrial benchtop muffle furnace efficient in temperatures of approximately 1200 ° C.

High-temperature level offers different temperature level abilities for different applications that customers will certainly use in commercial settings.

They aid in heating, annealing, and also tempering glass wares or crucibles.

4. Carbolite muffle furnace

Carbolite muffle heaters can be made used to heat products to high temperatures. They have a shielded chamber with a fuel burner at the bottom as well as an immune door at the top. These products are appropriate for usage from 30 to 3000 C.

5. Lab muffle furnace

Lab stifles heating systems help with heating tasks such as binder fatigue, sintering, as well as melting.

They use radiant heat transfer to heat products put inside the heater These can often be made use of to create certain temperature level conditions for clinical experiments or to make points in a controlled way.

Warm is equally distributed by metal baffles in between the burner.

2 Tips to Choose a Muffle Furnace Manufacturer

Firstly, if you assume there is a trustworthy muffle furnace manufacturer, the solution is that you can find several alternatives online such as Drawell.

Secondly, the only thing you need to keep in mind prior to purchasing a muffle furnace is to know the general ability of the equipment and also whether it is appropriates for your kind of market. Thus, understanding more concerning products and also choosing the ideal one is vital.