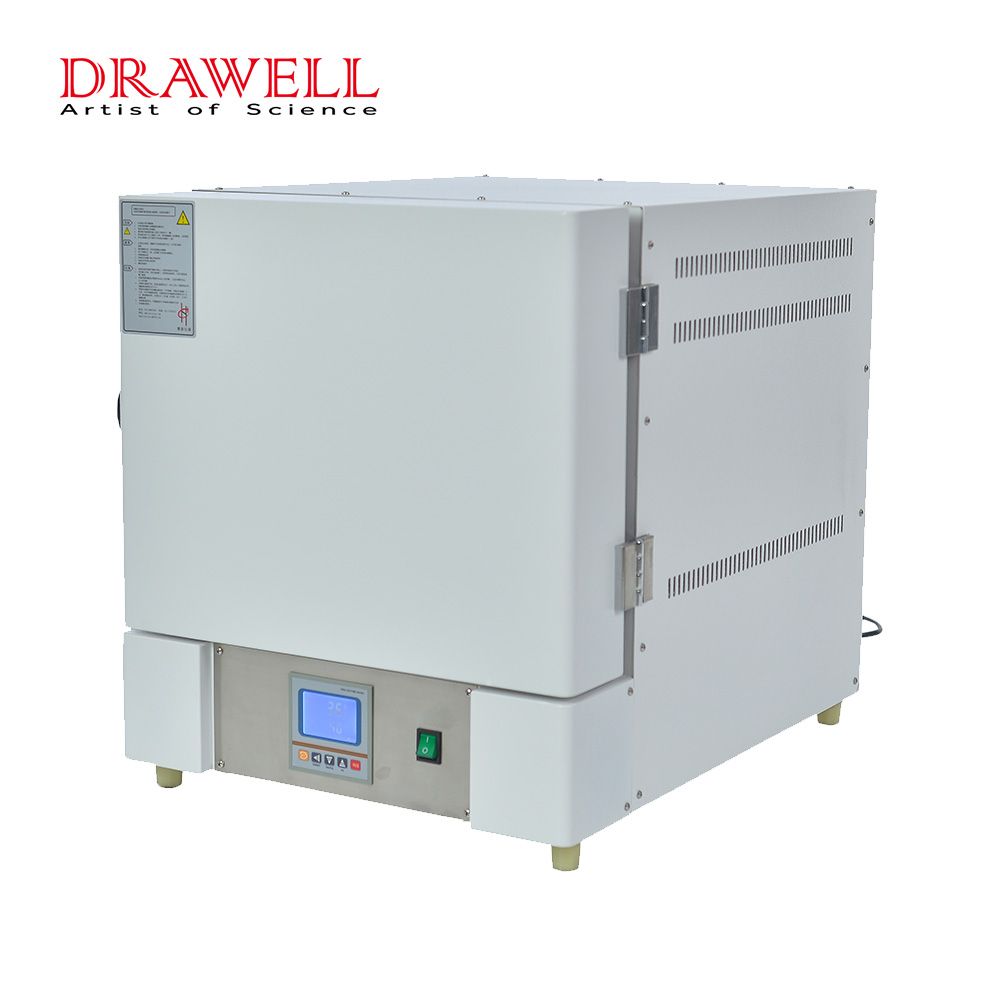

Muffle Furnace

Drawell is a trusted supplier of muffle furnaces, offering high-quality thermal processing equipment for various applications, including materials research, ceramics, and metallurgical testing. Their muffle furnaces are known for precise temperature control, rapid heating, and uniform heat distribution, ensuring reliable performance for critical processes such as ashing, sintering, and heat treatment. Built with durable materials and advanced safety features, Drawell muffle furnaces provide consistent, accurate results, making them a dependable choice for laboratories, industrial settings, and research institutions.

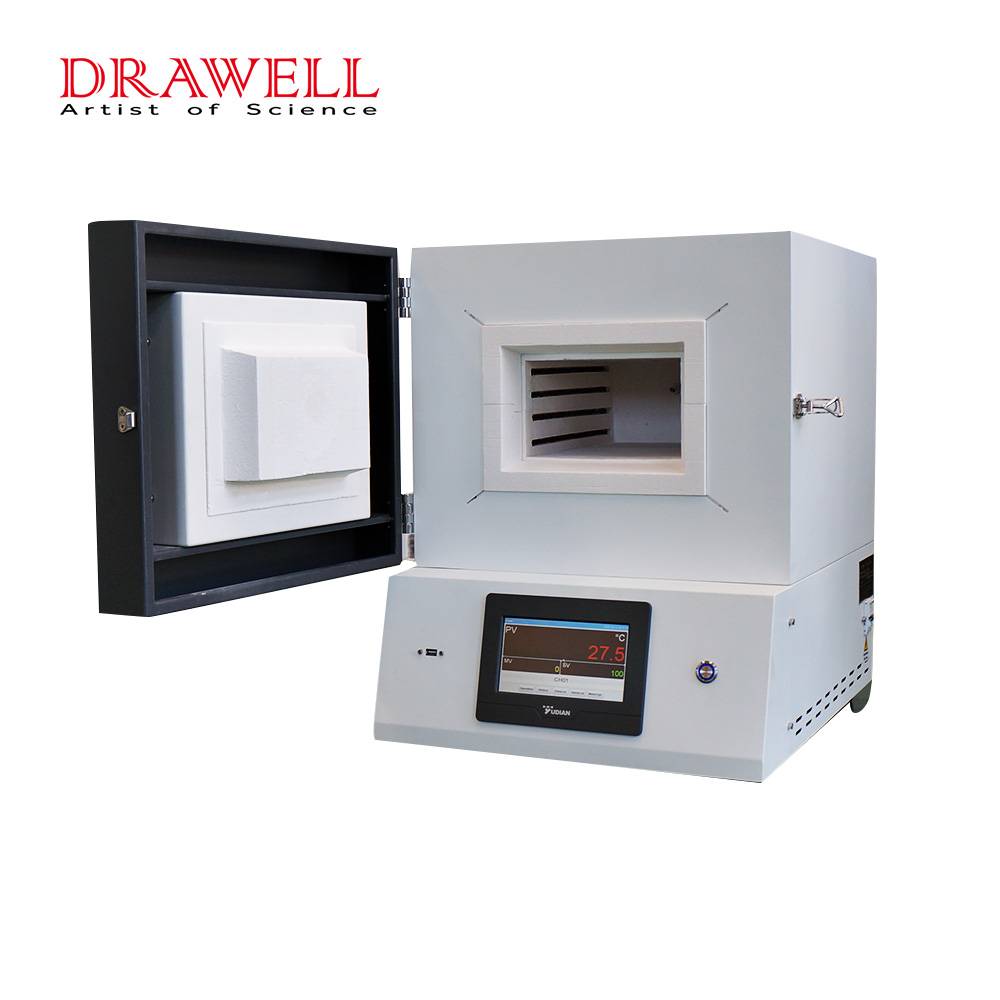

Features of Muffle Furnace

- Integrated Structure with elegant design

- Chamber Materials: Vacuum-forming ceramic fiber with the advantage of no powder drops off with high temperature and energy saving

- Heater: It use high-grade Mosi2(Molybdenum Disilicide Heaters)heating element

- Famous brand Microprocessor PID controller

- Long life type B thermocouple

- CE compliant;

- Built-in RS485 port and USB adaptor as optional settings for computer control. it needs to add extra fees.

Applications of Muffle Furnace

The muffle furnace belongs to the periodic operation type. The muffle furnace has many functions. The high-temperature muffle furnace can be used for high-temperature heating such as sintering, dissolution, and analysis of metals and ceramics. The muffle furnace is mainly used for laboratories, and industrial and mining enterprises, Scientific research units are used for elemental analysis and determination, as well as heating for heat treatment such as quenching, annealing, and tempering of small steel parts. High-temperature muffle furnaces can be used for high-temperature heating such as sintering, dissolution, and analysis of metals and ceramics. Specifically, there are mainly the following four application areas.

1. Coal quality analysis can be carried out in the muffle furnace, and the analysis of ash, moisture, ash melting point, volatile matter, ash components, elements, etc. can be tested. It can also be used as an ashing furnace by improving and adding a chimney.

2. Muffle furnaces also have important applications in the field of analytical chemistry. For example, the treatment of samples in water quality analysis and environmental analysis industries requires muffle furnaces. It can also be used in the process of oil analysis.

3. The muffle furnace can also be used in the medical field, for example, it can be used for the inspection of many drugs and the pretreatment of medical samples.

4. The muffle furnace can complete the thermal processing or processing of small workpieces in thermal processing, cement, building materials, and other fields.

How to Choose the Muffle Furnace Model?

1) Confirm the temperature

If the temperature is below 1000℃,recommend you the STM-1-10;

If the tempera is between 1000℃ and 1200℃,recommend you the STM-12 series;

If the tempera is between 1200℃ and 1400℃,recommend you the STM-14 series;

If the tempera is between 1400℃ and 1700℃,recommend you the STM-17 series;

2) Confirm the capacity

For different temperature, we have 6 option for the volume:3L;6L;8L;12L;18L;30L

Such as after you confirm STM-12series :

if you want 3L, you need choose the model: STM-3-12;

if you want 8L, you need choose the model: STM-8-12;

if you want 30L, you need choose the model: STM-30-12;

Meanwhile, except for the 6 options, we support the customization for the capacity.

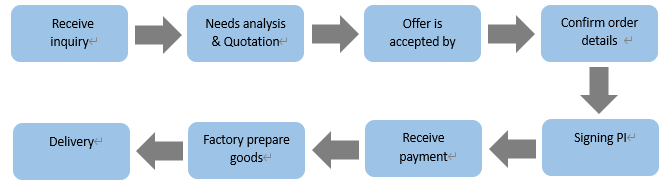

Order Process

Why Choose Us?

- Rich categories

- The products are market-oriented and exported to many countries in the world

- Perfect sales system, efficient and fast after-sales service

- On-time delivery rate reaches 100%

- High-cost performance

FAQ

- Are you a factory or trading company?

– We are a factory.

- What is the MOQ?

-(1) Normally, MOQ is 1 piece.

-(2) If there is no stock, the general MOQ is a big difference between different products. But the quantity still can be negotiated.

- Can we ask for a sample from your company?

– Sample is available, but we do not provide free samples.

- Do you provide OEM service?

– OEM service is available with the customer’s brand.

- Which payment can be acceptable?

– We accept the payment by L/C, T/T, Paypal, Western Union, etc.

- How about your delivery time?

– Generally, it will take 7-15 working days after receiving your advance payment. Depend on the quantity.

- What after-sales service do you provide?

– We could provide Online instruction; Real-time support by video call or voice chat; During warranty time, we can send product accessories when you need them for free; Technical guidance is free and ready forever.

- How long is the warranty?

– 1 year. it can be negotiated if you need an extended warranty.

- If you have other questions, you can contact us through:

– Email: [email protected]

– Tel.: 008613320353102