Accurate density measurement is essential in various industries, including pharmaceuticals, chemical engineering, food and beverage, and oil and gas. Density meters specifically designed for liquids play a crucial role in determining the density of liquids with precision and reliability. In this article, we will explore the principles underlying density meters for liquids, discuss the various types of density meters available, and examine the factors that can influence density measurements. Understanding these principles, types, and factors is vital for obtaining accurate density values and ensuring the quality and consistency of liquid products and processes.

What Is the Principle of Density Meter for Liquids?

The principles of density measurement involve understanding the relationship between mass, volume, and density. Density meters for liquids utilize various principles to measure the density of the liquid accurately. Here are some common principles employed in density meters for liquids:

- Oscillation: The principle of oscillation is frequently used in density meters for liquids. These meters measure the frequency or amplitude of oscillation of a sensing element immersed in the liquid. The frequency or amplitude changes in proportion to the density of the liquid, allowing for density measurement.

- Hydrostatic Weighing: The hydrostatic weighing principle is based on Archimedes’ principle. Density meters that use this principle measure the weight of the liquid displaced by an object submerged in the liquid. By comparing the weight of the liquid displaced to the weight of the object, the density of the liquid can be calculated.

- Resonance: Some density meters for liquids operate based on the principle of resonance. These meters induce vibrations in a sensing element submerged in the liquid. The resonant frequency of the element is influenced by the density of the liquid, and by measuring the frequency, the density can be determined.

- Coriolis Effect: The Coriolis effect is utilized in certain density meters for liquids. These meters use a vibrating tube that contains the liquid sample. The motion of the liquid in the vibrating tube is influenced by the Coriolis effect, which is proportional to the density of the liquid. By measuring the Coriolis force or the phase shift caused by it, the density of the liquid can be determined.

- Sound Speed: The speed of sound in a liquid is influenced by its density. Some density meters for liquids use this principle by emitting ultrasonic waves through the liquid and measuring the time it takes for the waves to travel. The density of the liquid can be calculated based on the speed of sound and the travel time.

These principles are employed in various types of density meters for liquids, such as oscillating U-tube density meters, digital density meters, vibrating element density meters, and ultrasonic density meters. Each principle offers its own advantages and limitations, and the choice of density meter depends on factors such as the type of liquid, required accuracy, and specific application requirements. Next, let’s talk about the common types of density meters for liquids.

What Are the Types of Density Meters for Liquids?

- Oscillating U-Tube Density Meters: Oscillating U-tube density meters are widely used for liquid density measurement. They consist of a U-shaped tube partially filled with the liquid sample. The difference in liquid levels in the two arms of the U-tube corresponds to the density difference between the sample and a reference liquid. These meters are suitable for a wide range of liquid samples and provide accurate density readings.

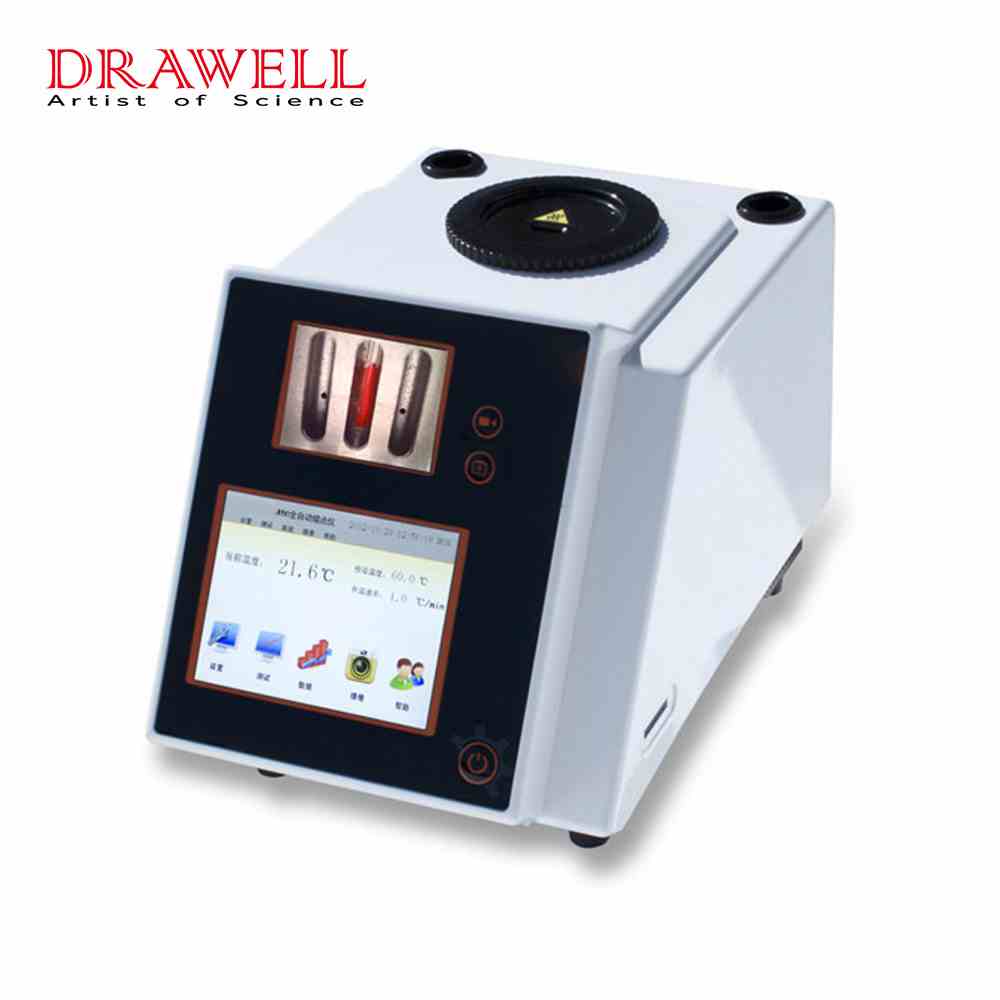

- Digital Density Meters: Digital density meters equipped with sensor probes or measuring cells are commonly used for liquid density measurement. These meters utilize various principles such as oscillation, resonant frequency, or forced oscillation to measure the density of the liquid. They provide accurate and precise density readings and are often used in laboratory and industrial settings.

- Vibrating Element Density Meters: Vibrating element density meters employ the principle that the frequency of vibration of a solid object immersed in a liquid is influenced by the density of the liquid. By measuring the frequency change, the density of the liquid can be determined. These meters are suitable for a wide range of liquid samples and offer high accuracy and reliability.

- Refractometers: While primarily used for measuring refractive index, refractometers can also provide indirect density measurements for liquids. The refractive index of a liquid is influenced by its density. By measuring the refractive index using a refractometer, the density can be estimated. However, it is important to note that this method relies on empirical correlations and may not provide the same level of accuracy as dedicated density meters.

- Microwave Density Meters: Microwave density meters can also be used for measuring the density of liquids. These meters rely on the principle that the speed of microwaves passing through a liquid is affected by its density. By measuring the phase shift or attenuation of the microwave signal, the density of the liquid can be determined.

When selecting a density meter for liquids, factors such as the viscosity of the liquid, temperature range, accuracy requirements, and operational conditions should be considered to choose the most suitable type of density meter for the specific application.

What Factors Affecting Measurement of Density Meters for Liquids?

When using a density meter for liquids, several factors can affect the accuracy and reliability of density measurements. It is important to consider and account for these factors to ensure precise results. Here are some key factors that can influence density measurement when using a density meter for liquids:

- Temperature: Temperature variations can significantly impact the density of liquids. Most density meters have temperature compensation features or require temperature inputs to adjust the density readings accordingly. It is crucial to measure and control the temperature of the liquid being tested to obtain accurate density measurements.

- Viscosity: The viscosity of a liquid can affect the flow and movement of the liquid within the density meter, potentially impacting the measurement. High-viscosity liquids may require special handling or specific density meter designs capable of accommodating their properties.

- Air Bubbles: Air bubbles trapped within the liquid sample can affect the density measurement. These bubbles can alter the effective volume and density of the liquid, leading to erroneous readings. It is essential to degas or remove air bubbles from the liquid before measurement, if possible.

- Sample Homogeneity: The uniformity or homogeneity of the liquid sample can impact density measurements. If the liquid contains suspended particles, emulsions, or other inhomogeneous components, it may lead to inconsistent density readings. Proper sample preparation, including thorough mixing and removal of any settled particles, is necessary for accurate measurements.

- Contamination: Contaminants or impurities in the liquid can introduce errors in density measurements. Foreign substances that have different densities or chemical compositions from the liquid being tested can affect the density readings. It is important to ensure that the liquid sample is clean and free from any contamination.

- Calibration: Regular calibration of the density meter is crucial for accuracy. Calibration involves comparing the density meter readings against known standards or reference liquids with known densities. Proper calibration ensures that the density meter is providing reliable and accurate measurements.

- Instrument Limitations: Each density meter has its own limitations and specifications. It is essential to understand the capabilities, operating range, and limitations of the density meter being used. Adhering to the manufacturer’s guidelines and instructions for proper usage is important to obtain accurate density measurements.

Conclusion:

By recognizing the principles, exploring the types, and considering the factors affecting density measurement for liquids, professionals can optimize their measurement processes, enhance product quality, improve process efficiency, and meet stringent industry standards.

Accurate density measurement serves as a crucial parameter in quality control, process optimization, and research and development. With advancements in technology and continued research, density meters for liquids continue to evolve, offering enhanced precision, ease of use, and expanded measurement capabilities.

Please come to our site to stay informed and up-to-date with the latest advancements about density meters and other analytical instruments.