Centrifugation is a fundamental process used in various industries and scientific fields to separate particles from a suspension based on their density, size, or shape. Centrifuges come in a variety of types, each suited for different applications. One crucial component of centrifuges is the rotor, which plays a significant role in the efficiency and effectiveness of the separation process. In this article, we will explore the different types of centrifuges and their rotors, as well as factors to consider when choosing the right centrifuge for specific applications.

Fundamentals of Centrifugation

Centrifugation relies on the concept of relative centrifugal force (RCF), which is the effective force a particle experiences during rotation. When a mixture is subjected to high-speed rotation, denser particles migrate outward faster than lighter ones, leading to separation based on density. The speed of rotation and the design of the centrifuge determine the force exerted on the particles, affecting the separation efficiency. Higher speeds and larger rotor diameters generate greater RCF, causing denser particles to migrate outward and settle at the bottom of the tube.

This process allows for the separation of various components in a mixture, such as cells, organelles, proteins, and DNA.

Types of Centrifuges

Centrifuges can be classified based on various criteria such as their design, application, rotational speed, and the principle of separation. Here are some common classifications:

1. From Design:

- Fixed-Angle Centrifuges: In these centrifuges, tubes are held at a fixed angle relative to the rotor axis. They are commonly used for pelleting particles.

- Swinging-Bucket Centrifuges: Tubes swing outwards as the rotor spins, allowing for better separation of components. They are often used for larger volumes and higher capacities.

- Continuous Flow Centrifuges: These centrifuges allow continuous separation of particles from a continuous flow of liquid. They are commonly used in industrial applications.

2. From Application:

- Clinical Centrifuges: Designed for medical and clinical applications such as separating blood components or other bodily fluids.

- Laboratory Centrifuges: Used in research laboratories for various applications including DNA separation, protein purification, and cell isolation.

- Industrial Centrifuges: Larger and more robust centrifuges used in industrial settings for processes like oil separation, wastewater treatment, and chemical processing.

3. From Rotational Speed:

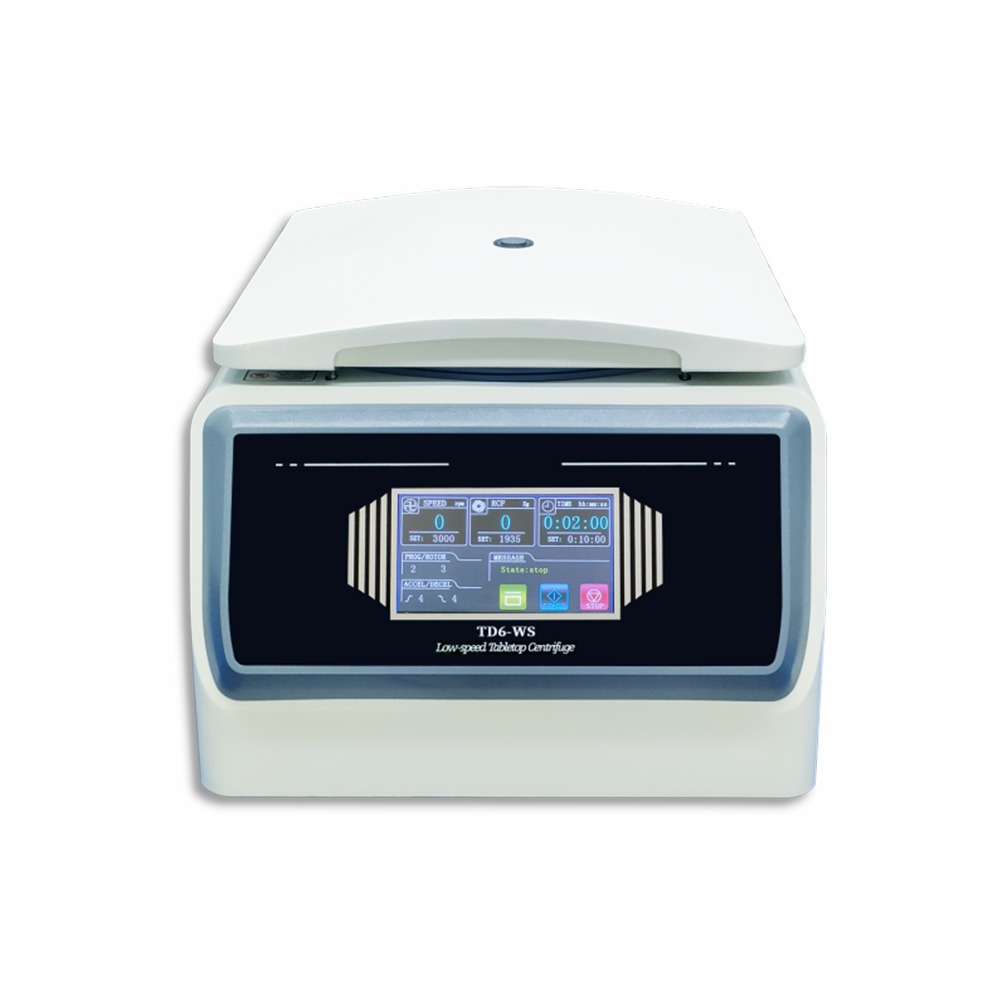

- Low-Speed Centrifuges: Typically operate at speeds up to 5,000 rpm and are used for gentle separation of particles.

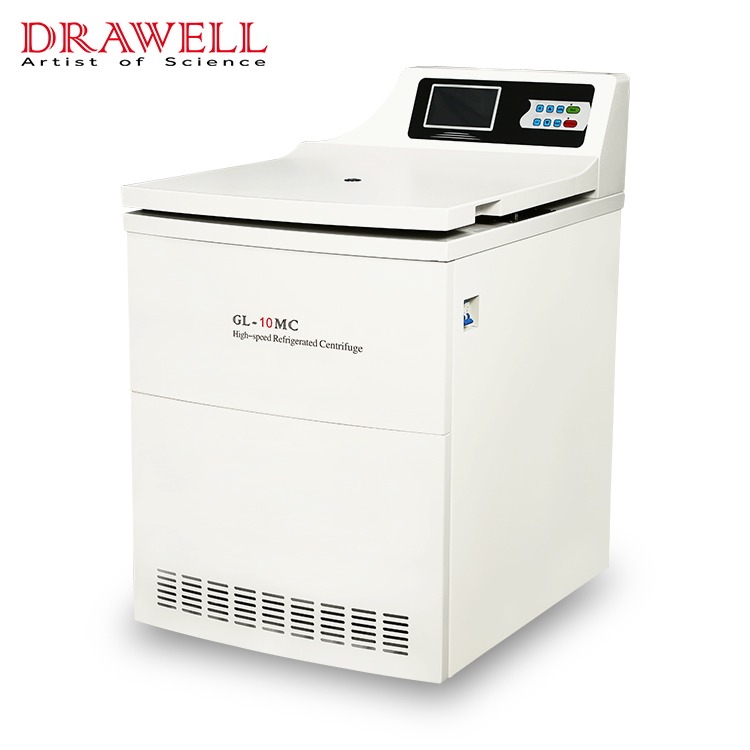

- High-Speed Centrifuges: Operate at speeds ranging from 10,000 to over 100,000 rpm and are used for rapid and efficient separation.

4. From Principle of Separation:

- Differential Centrifugation: Relies on the different sedimentation rates of particles based on their size, shape, and density.

- Density Gradient Centrifugation: Utilizes a density gradient medium to separate particles based on their buoyant density.

- Isopycnic Centrifugation: Particles migrate to their position in the centrifuge tube where their density equals the density of the surrounding medium.

5. From Size and Capacity:

- Microcentrifuges: Small benchtop centrifuges used for small volumes, commonly found in molecular biology and biochemistry labs.

- Benchtop Centrifuges: Larger than microcentrifuges, used for moderate volumes and capacities, commonly found in clinical and research laboratories.

- Floor-Standing Centrifuges: Larger capacity centrifuges often used in industrial and large-scale research applications.

These classifications provide a framework for understanding the different types of centrifuges and their respective uses across various fields and industries. Drawell can provide you laboratory centrifuges from different rotational speed, size and capacity. Please feel free to contact us for your needs.

Types and Applications of Rotors used in Centrifugation

The rotor is the heart of a centrifuge, housing the tubes or containers holding the samples. Centrifuge rotors can be classified based on various factors such as their design, capacity, speed, and intended applications. Different designs to accommodate various sample types, volumes, and separation requirements. Here are some common classifications along with their applications:

| Rotor Type | Features | Applications |

| Fixed Angle Rotors | Tubes held at a fixed angle | Separation of particles or cells from suspension (e.g., molecular biology, biochemistry, clinical diagnostics) |

| Swinging Bucket Rotors | Tubes swing outwards during centrifugation | Density gradient centrifugation |

| Vertical Rotors | Tubes loaded vertically, spins around a vertical axis | Sedimentation of larger particles, high-capacity sample processing (e.g., industrial, research settings) |

| Horizontal Rotors | Spins around a horizontal axis, tubes loaded parallel to axis of rotation | High-speed separations, preparative ultracentrifugation, isolation of subcellular components |

| Fixed Speed Rotors | Operates at fixed speed, typically high speeds | Isolation of macromolecules, subcellular particles, viruses, cellular organelles |

| Variable Speed Rotors | Speed can be adjusted | Versatile use across various fields (e.g., molecular biology, biochemistry, microbiology, clinical diagnostics) |

| Microcentrifuge Rotors | Designed for microcentrifuges, higher speeds | DNA/RNA extraction, protein purification, PCR, other molecular biology applications |

| Large Capacity Rotors | Accommodates larger volumes | Large-scale cell culture harvesting, purification of biomolecules, bioprocessing |

| Zonal Rotors | Separates based on sedimentation coefficients | Fractionation of complex mixtures (e.g., isolation of lipoproteins, viruses) |

| Preparative Rotors | Large-scale purification and isolation | Isolation of proteins, nucleic acids, viruses, other biomolecules for research or industrial purposes |

This table provides a clear breakdown of the different types of centrifuge rotors, their features, and their respective applications. There may be variations or combinations of rotor types to suit specific centrifugation requirements in various scientific and industrial fields.

Conclusion

In conclusion, understanding the various types of centrifuges and their rotors is essential for researchers, clinicians, and industrial professionals alike. Whether performing molecular biology experiments, clinical diagnostics, or large-scale bioprocessing, selecting the right centrifuge and rotor configuration is crucial for achieving optimal results. Laboratory centrifuge suppliers play a pivotal role in providing a wide range of centrifuge systems tailored to specific applications, ensuring researchers have access to the latest advancements in centrifugation technology. By staying informed about the classifications and features of centrifuge rotors, scientists can make informed decisions to meet their centrifugation needs efficiently and effectively, ultimately advancing research, diagnostics, and industrial processes.