In laboratory settings, mixing is a fundamental process required in chemistry, biology, pharmaceuticals, and materials science. Two common stirring devices, magnetic stirrers and overhead stirrers, are often used for blending liquids, suspensions, and viscous substances. While both serve the same basic purpose, their mechanisms, capabilities, and ideal use cases differ significantly. Understanding the strengths and limitations of magnetic stirrers vs. overhead stirrers is crucial for selecting the most suitable tool for your specific application.

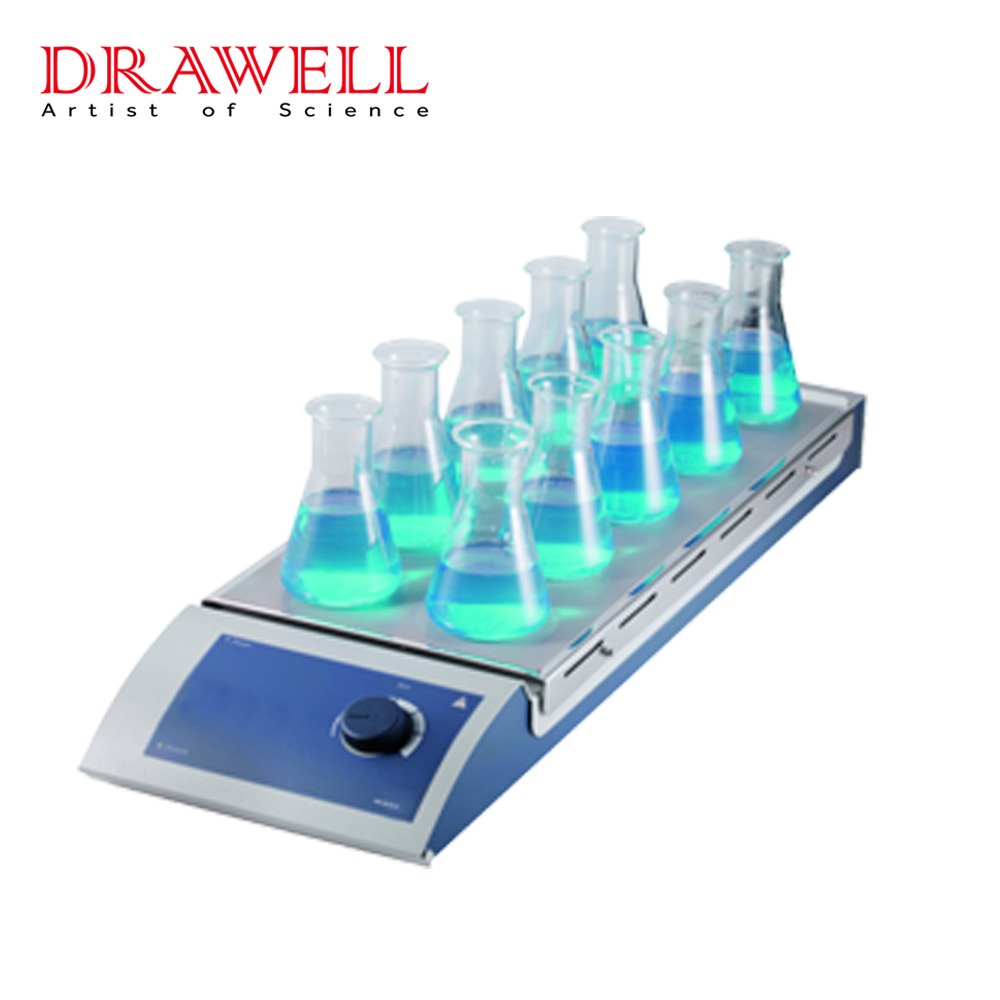

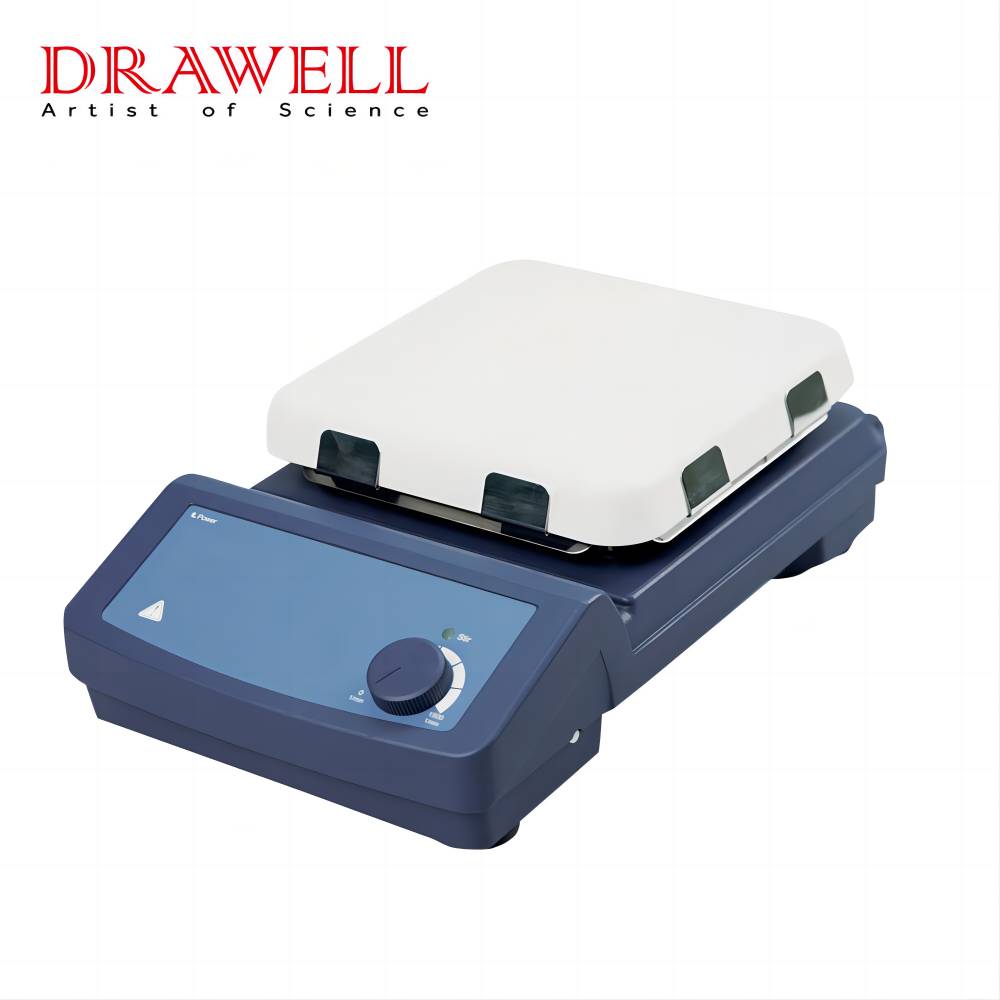

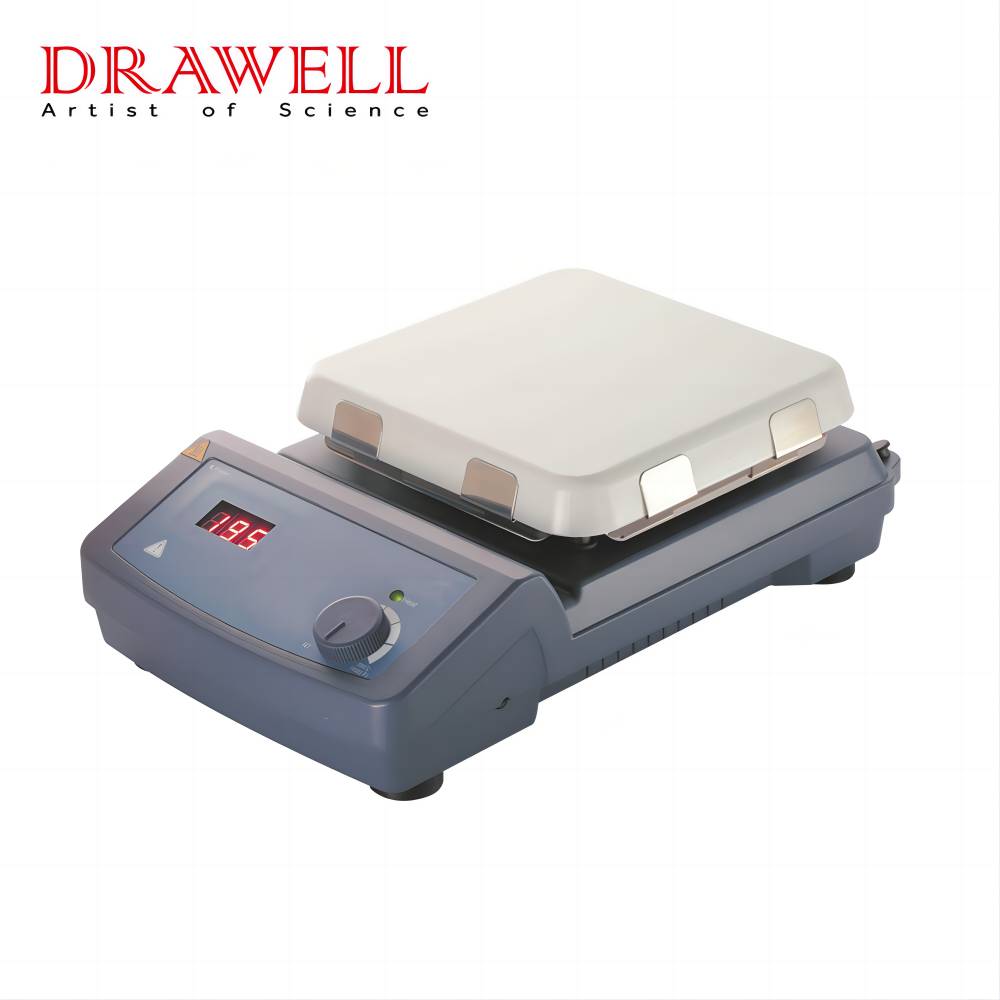

What are Magnetic Stirrers

Magnetic stirrers are laboratory devices that use a rotating magnetic field to mix liquids. They’re particularly common in chemistry, biology, and medical labs for tasks requiring consistent and contamination-free stirring of solutions.

How They Work

A magnetic stirrer operates by placing a magnetic stir bar (also called a stir rod or flea) inside the liquid container. Beneath the container, the stirrer housing contains a rotating magnet or a series of electromagnets connected to a motor. When activated, the rotating magnetic field causes the stir bar to spin rapidly inside the container, thereby stirring the liquid. Advanced digital magnetic hotplate stirrers integrate heating elements to simultaneously stir and heat the solution.

Advantages and Limitations

| Advantages | Limitations |

| Minimal Contamination: With no external part entering the solution (other than the easily sterilizable stir bar), the risk of contamination is significantly reduced. | Limited Mixing Volume: Magnetic stirrers are typically effective only up to around 5 liters of liquid; beyond that, the stir bar may not spin efficiently. |

| Compact and Quiet Operation: They are small, lightweight, and operate quietly, making them suitable for confined laboratory spaces and sensitive environments. | Not Suitable for High Viscosity Solutions: Thick or dense liquids can cause the stir bar to decouple from the magnetic field, halting effective mixing. |

| Easy to Use and Maintain: With minimal moving parts and a simple design, they are user-friendly and require very little maintenance. | Limited Torque and Power: They lack the mechanical strength needed for high-torque stirring, making them unsuitable for emulsions or suspensions. |

| Ideal for Closed or Sterile Systems: Perfect for mixing in sealed containers like culture flasks or reaction vessels where sterile conditions must be preserved. | Stir Bar Wear: Over time, stir bars may lose their magnetic strength or become coated with residues that affect performance. |

| Cost-Effective for Small-Scale Tasks: They are an affordable option for labs working with small volumes or routine sample preparation. |

Applications

Magnetic Stirrers are ideal for:

- Routine lab mixing in small beakers or flasks

- Dissolving salts in water

- Buffer preparation

- Cell culture media mixing

- Applications requiring sterile, closed systems

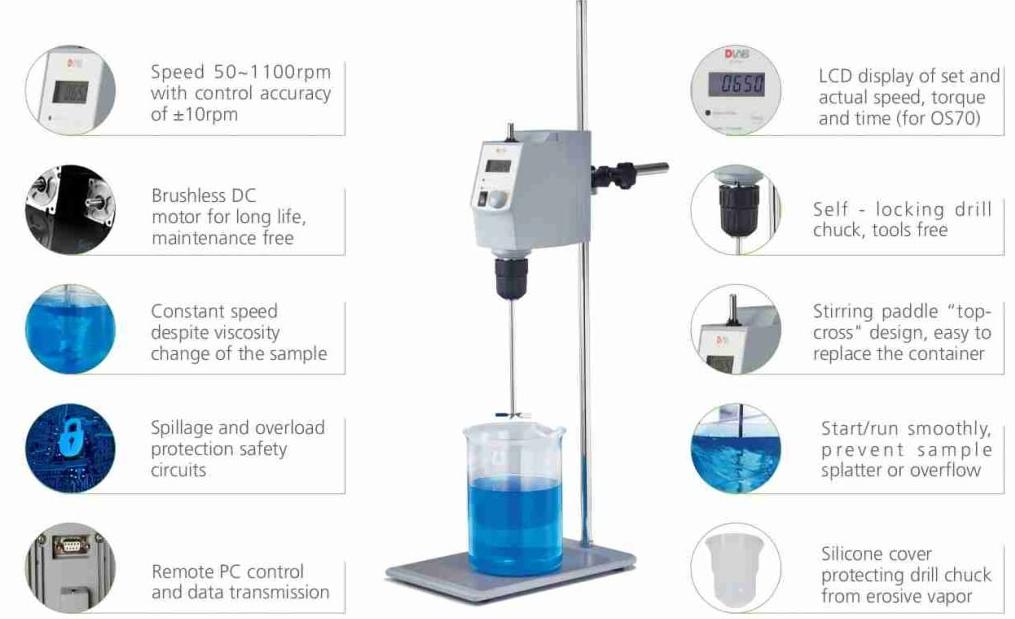

What are Overhead Stirrers

Overhead stirrers are robust laboratory devices designed to mix liquids using a motor-driven shaft and stirring tool (such as paddles, blades, or impellers) that are immersed directly into the solution. Unlike magnetic stirrers, which rely on a magnetic field and stir bar, overhead stirrers provide direct mechanical stirring, making them suitable for larger volumes and high-viscosity substances.

How They Work

An overhead stirrer consists of a motorized drive unit mounted above a container. A shaft extends downward into the liquid, where a stirring tool (often interchangeable) rotates to agitate the mixture. Speed and torque can be precisely controlled to ensure thorough and consistent mixing, even in demanding conditions.

Advantages and Limitations

| Advantages | Limitations |

| Handles High Viscosity: They can stir thick, viscous materials like gels, emulsions, slurries, and polymers that magnetic stirrers cannot. | More Complex Setup: Requires proper alignment and mounting above the vessel, which can take up more space and effort. |

| Suitable for Large Volumes: Effective for stirring liters to tens of liters of solution, even up to industrial-scale batches in pilot labs. | Increased Risk of Contamination: Since the shaft and stirrer enter the solution, careful cleaning and sterilization are necessary, especially in sensitive applications. |

| Customizable Stirring Tools: Users can select from various impellers (propeller, paddle, anchor, etc.) to match specific fluid dynamics or processing needs. | Higher Cost: Typically more expensive than magnetic stirrers due to their powerful motors and versatile design. |

| High Torque and Power: Overhead stirrers provide stronger mixing forces, enabling thorough blending of dense or layered substances. | Maintenance Required: Bearings, shafts, and motor components may require periodic servicing or replacement over time. |

| Precision Control: Advanced models offer digital speed control, timers, and feedback systems to maintain consistent mixing conditions. |

Applications

Overhead Stirrers are suited for:

- Polymer synthesis

- Emulsification and dispersion of solids

- Fermentation processes

- Mixing of viscous materials such as gels, creams, or heavy suspensions

- Scale-up processes in industrial or pilot-scale labs

Key Differences Between Magnetic Stirrers vs. Overhead Stirrers

| Aspect | Magnetic Stirrers | Overhead Stirrers |

| Mixing Method | Magnetic field drives a stir bar inside the container | Motor-driven shaft with impeller or paddle inside the solution |

| Ideal Volume Range | Small to medium (typically ≤ 5 liters) | Medium to large (up to tens of liters or more) |

| Viscosity Suitability | Best for low-viscosity liquids | Suitable for high-viscosity or dense mixtures |

| Contamination Risk | Low (only stir bar contacts liquid) | Higher (shaft and tool immersed in solution) |

| Ease of Use | Very easy; minimal setup | Requires mounting and alignment |

| Power and Torque | Limited | High; capable of handling heavy-duty mixing |

| Speed and Control | Basic speed control | Advanced control (digital speed, torque, and timers) |

| Maintenance | Minimal (mainly cleaning stir bars) | Requires more maintenance (shafts, seals, motor parts) |

| Heating Option | Often includes built-in heating (LCD digital magnetic hotplate stirrer models) | Requires external heating source (e.g., heated vessel) |

| Sterile Applications | Highly suitable due to closed-system compatibility | Less suitable; needs careful cleaning to maintain sterility |

| Size and Footprint | Compact and portable | Larger footprint, needs stand or support |

| Cost | Generally lower cost | Higher initial investment |

Key Factors to Consider for Choosing Between Magnetic Stirrers vs. Overhead Stirrers

When choosing between magnetic stirrers and overhead stirrers, several key factors should be considered to ensure optimal performance, reliability, and suitability for your specific laboratory tasks. Each type of stirrer offers unique benefits, and the decision largely depends on the nature of your application, the properties of the substances involved, and operational preferences.

- Volume of Liquid

The amount of liquid you need to mix is a primary consideration. Magnetic stirrers are ideal for small to medium volumes, typically up to 5 liters. Beyond that, the stir bar may not provide sufficient agitation. Overhead stirrers, on the other hand, are designed to handle larger volumes effectively, even in industrial or pilot-scale processes.

- Viscosity of the Solution

Low-viscosity liquids, such as aqueous solutions or buffers, are well-suited for magnetic stirrers. In contrast, highly viscous samples—like gels, oils, or polymer suspensions—require the torque and power that only overhead stirrers can deliver without loss of stirring efficiency.

- Type of Application

Routine, non-intensive applications such as mixing culture media or titrations typically benefit from the simplicity of magnetic stirrers. More demanding tasks like emulsification, crystallization, or reactions that involve suspensions or sediments are better suited for overhead stirrers due to their superior mechanical action and flexibility in stirrer blade design.

- Contamination Risk and Sterility Requirements

Magnetic stirrers are advantageous in sterile environments because the only component in contact with the liquid is the easily sterilized stir bar. Overhead stirrers involve direct shaft immersion, increasing the risk of contamination and requiring meticulous cleaning, especially in biological or pharmaceutical applications.

- Temperature Control

Some magnetic hotplate stirrers come with integrated heating functions, allowing simultaneous mixing and heating. While overhead stirrers typically don’t include a heating mechanism, they can be used with heated vessels or jackets. If heating is a critical part of your process, ensure your chosen stirrer setup accommodates that requirement.

- Precision and Control

Digital overhead stirrers often provide more precise speed control and consistent torque, which are important for reproducibility in research and scale-up applications. Magnetic stirrers offer basic speed adjustments, sufficient for simple tasks but not ideal when exact control is essential.

- Space and Setup

Magnetic stirrers are compact, portable, and require minimal bench space. Overhead stirrers are bulkier, require mounting support, and may occupy more space due to their vertical configuration. Consider your lab layout and workspace constraints when making a choice.

- Budget Constraints

Magnetic stirrers are generally more cost-effective and require less maintenance. Overhead stirrers represent a higher initial investment but are justified when complex or heavy-duty mixing is needed.

- Safety Considerations

Overhead stirrers, due to their powerful motors and rotating shafts, require more attention to safe operation. Magnetic stirrers pose minimal mechanical risk, making them safer for basic lab use and training environments.

For general laboratory use and sterile environments, magnetic stirrers are a practical and affordable solution.

For demanding applications involving heavy or viscous mixtures, overhead stirrers provide the power and control required.

Final Thoughts

The choice between a magnetic stirrer and an overhead stirrer ultimately depends on your sample volume, viscosity and desired precision. Before investing in a stirrer, consider your specific application requirements and the potential for scaling up in the future. Selecting the right stirring technology can improve experimental reproducibility, process efficiency, and lab productivity.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.