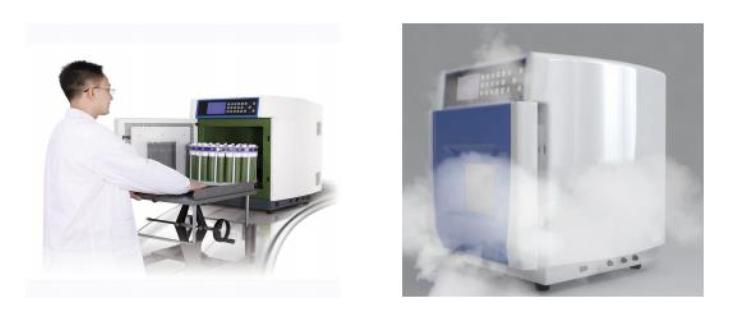

In modern analytical labs, the requirement for high-throughput exact and reproducible analysis of elements has led to the wide adoption for microwave digestionsystems. These systems aid when it comes to preparing samples for later analysis by breaking up complex matrices into digestible formats. Its seamless integration with analytical instruments like ICP-MS (Inductively Coupled Plasma Mass Spectrometry), AAS (Atomic Absorption Spectroscopy) and ICP-OES (Inductively Coupled Plasma Optical Spectrometry) has revolutionized the process in analysis of elements by enhancing efficiency, precision and security.

Why Integrate Microwave Digestion Systems with Analytical Instruments

- A Foundation for Reliable Sample Preparation

Microwave digestion offers a regulated process for reproducible decomposition of samples by using concentrated acids and microwave energy. In contrast to traditional open-vessel acid digestion microwave digestion takes place in closed systems that are subject to high temperatures and pressures which significantly accelerates the breakdown of organic as well as organic substances. This leads to clear and consistent digests that are perfect in ultra-trace or trace analysis of elements.

But, despite these benefits, if the process of converting from digestion to analysis isn’t smooth, labs could face issues, delays, as well as contamination. Integration is not only advantageous, but vital.

- Reducing Errors and Enhancing Traceability

Handling samples manually between analysis and preparation can create significant variations. Through using digesting microwave systems into the analytical workflow, labs are able to minimize human error while ensuring more traceability. For instance digestion systems with scanners for barcodes as well as LIMS connectivity permit the automatic tracking of samples through every step of. From digestion parameters through analytical outcomes, each step can be tracked and verified, assuring the integrity of data.

Furthermore, digestion protocols that are standard can be customized to meet the specific requirements of particular analytical instruments. This will ensure that the samples are made in a manner which maximizes the detection limits and reduces matrix interferences, which results in more precise and reliable results.

- Accelerating Turnaround and Improving Efficiency

Integration speeds up the sample preparation-to-analysis pipeline. In high-throughput laboratories, such as those in environmental testing, food safety, and pharmaceuticals–every minute saved per sample translates into a substantial boost in productivity. Digestion vessels that are compatible with autosamplers and direct-to-instrument transfer design can further reduce bottlenecks. Laboratories are able to process larger amounts of samples with less time and without sacrificing quality or accuracy.

- Supporting Regulatory Compliance and Quality Standards

The integration of systems makes it easier for labs to adhere to industry standards and regulations. It doesn’t matter if it’s ISO 17025, EPA Method 3052 or USP guidelines traceable and standardised workflows aid in ensuring that data analysis is auditable and defensible. Integration provides full documentation of digesting and analysis processes, that are crucial to pass audits and keep certifications.

- Enabling Smart Laboratory Operations

The modern microwave digestion systems come with intelligent software that is capable of communication directly between analytical instrument and central laboratories systems. These systems can suggest optimized digestion parameters based on the sample type and the intended analysis and simultaneously record every operating condition. Certain systems can even allow remote diagnostics and operation which will allow for fully automated and digitally connected labs.

How to Integrate Microwave Digestion System with Different Analytical Instruments

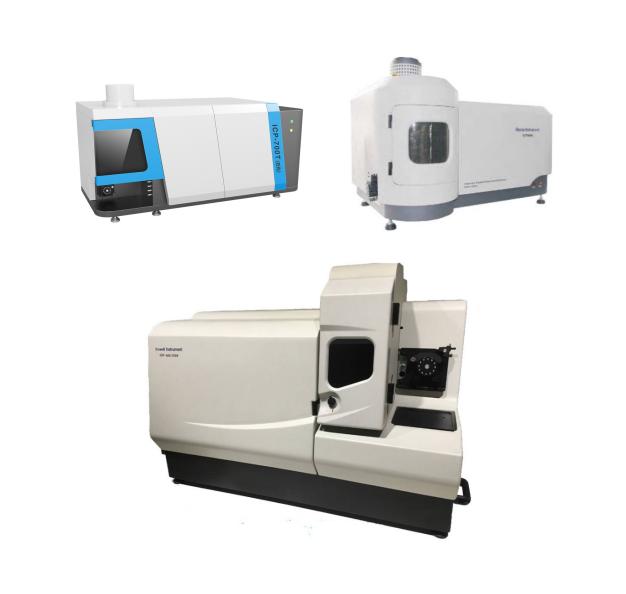

1. Integration with ICP -MS and ICP -OES

Why Integrate

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Optical Emission Spectroscopy (ICP-OES) are extremely sensitive methods for analyzing elements. Combining them with microwave digestion guarantees:

- Minimized contamination (closed-system transfer).

- Improved accuracy (reduced manual handling errors).

- Increased capacity (automated sampling introduction).

How It Works

- Automated systems for sample transfer (e.g. automaticsamplers) direct inject digested samples directly into the ICP.

- Inline dilution/filtration is compatible with ICP detection limitations.

- Software synchronization enables method matching between digest and analysis.

Key Benefits

- Rapider analysis and fewer manual steps.

- Lower risk of loss of samples or contamination.

- Improved reproducibility of the analysis of trace elements.

2. Integration with Atomic Absorption Spectroscopy (AAS)

For laboratories that focus on specific metals, the integration of microwave digestion in conjunction with the AAS (flame or graphite furnace) guarantees optimal samples preparation. Inline filtering and automated dilution could be added to improve accuracy.

How It Works

- Automated liquid handling transfer digested samples to the AAS.

- Pre-digestion spike/recovery checks ensure method accuracy.

- Temperature-controlled transfer prevents analyte degradation.

Key Benefits

- Reduction of interferences caused by organics that have not been digested.

- More precise quantitative analysis.

- The workflow is streamlined for routine testing.

3. Integration with Ion Chromatography (IC)

For analysis of speciation (e.g. for determining the different arsenic forms or the chromium) microwave digestion could be integrated to ion chromatography systems. The proper integration makes sure that the digested samples are promptly examined to avoid degradation of species.

How It Works

- Low-temperature digestion preserves analyte species.

- Immediate post-digestion cooling prevents redox reactions.

- Direct injection interfaces minimize sample handling.

Key Benefits

- A precise analysis of speciation.

- Lower risk of species transformation.

- High-throughput tests for food safety and environmental testing.

4. Robotic & Automated Sample Handling Systems

Why Use Robotics

- Eliminates human error from transfer of samples.

- Allows 24/7 operation for large-volume labs.

- It ensures traceability by using barcode tracking.

Key Technologies

- Liquid handling robots to ensure precise transfer.

- Automated filtration and dilution stations.

- Integration of lab informatics (LIMS compatible).

Challenges and Solutions in Integrating Microwave Digestion Systems with Analytical Instruments

| Challenge | Description | Solution |

| Cross-contamination risk | Manual transfer can cause contamination of tools, vessels or even hands. | Utilize closed-vessel systems, acid-washed containers and automatic transfer systems. |

| Incompatibility between sample containers | The digestion vessels may not fit into autosamplers in analytical instruments. | Use digesters that are compatible with your system or use racks that are standard which match the instrument’s designs. |

| Loss of sample during transfer | The effects of spillage, evaporation or adsorption may affect the accuracy of samples. | Integrate sealed dilution system and direct injection mechanisms whenever possible. |

| Insufficient software/data synchronization | The sample metadata and the conditions for digestion might not be compatible with analysis systems. | Integrate Laboratory Information Management Systems (LIMS) or other compatible software platforms. |

| The overload of the instrument or bottlenecks | The high throughput of digestion can overpower analytical instruments. | Use scheduling or queuing programs and optimize batch methods. |

| Variable digestion efficiency | Different sample types require different digestion protocols. | Make use of digestibility profiles programmable and method libraries that can be tailored to the sample matrixes. |

| The gaps in traceability and compliance | Inconsistent data trails may compromise audits by regulators. | Implement barcode tracking as well as digital records from digestion through the final analysis. |

| System compatibility and maintenance | Different vendors could have different integration standards. | Choose open architecture systems, or choose vendors that allow multi-vendor integration. |

| Sample stability after digestion | Digested solutions can degrade prior to an analysis. | Utilize refrigeration or time-controlled analysis workflows to ensure integrity of the sample. |

| Complexity of workflow and training | Staff members may have difficulty maintaining and operating integrated systems. | Offer cross-training, SOPs, and user-friendly interfaces to ensure smooth operation. |

Future Trends in Integrating Microwave Digestion Systems with Analytical Instruments

In laboratories that strive to increase efficiency, precision and regulatory compliance, that integration of microwave digestion systems with analytical instruments is advancing beyond traditional workflows. Technology advancements, digital connectivity and sustainability targets have changed the way samples are prepared and analyzed. The future will bring more efficient, faster and more automated integration models that are set to revolutionize the field of analytical chemistry.

- Fully Automated Sample-to-Result Pipelines

One of the biggest trending areas is the development completely automated processes in which samples go through digestion, to analysis without any human involvement. The systems will be incorporating robots for sample handling, automatic diluting, and synchronized injecting into instruments like ICP-MS or ICP-OES. This technology not only speeds up throughput, but also decreases human error and risk of contamination and is perfect for labs with high volumes and GMP-regulated labs.

- AI-Driven Method Optimization

Artificial Intelligence (AI) is starting to play an important role in the optimization of digestion parameters as well as analytical techniques. Future systems will employ AI algorithms to modify digestion programs based on the composition of samples as well as historical data and feedback from the instrument. Self-optimizing integration can improve precision and reproducibility, particularly when multi-matrix systems are used, which require manual tuning.

- Real-Time Data Synchronization and LIMS Integration

The integration and integration with Laboratory Information Management Systems (LIMS) will become more efficient and in real-time. Analytical instruments and digestion units will continuously exchange data which will allow laboratories to keep track of the status of their samples, verify results on their own, and also flag abnormalities immediately. Cloud-based platforms also allow remote monitoring and the ability to make decisions.

- Compact, Bench-Top Integration Platforms

Space-saving design is emerging as a need for labs that are small and mobile. In the future, integration configurations are expected to feature smaller, modular systems which combine analysis and digestion with a single benchtop footprint. The systems will be beneficial to laboratories that are located in the field or research institutes as well as facilities for quality assurance that have small lab spaces.

- Enhanced Vessel and Consumable Compatibility

Manufacturers are anticipated to adopt universal standards for digesting vessels, caps and racks in order to guarantee an immediate compatibility with auto samplers for analytical instruments. RFID and magnetic-tagged vessels could facilitate the automatic identification of digesting parameters, increasing the traceability of the vessel and decreasing workload for operators.

- Green Chemistry and Sustainable Practices

Sustainability is increasingly impacting the process of designing digestion-analytical workflows. The next phase of integration will focus on reducing the amount of reagents required and recycling acid waste and enhancing efficiency in energy use. Labs will also search for solutions that permit low-temperature digestion of volatile compounds which will reduce environmental impacts.

- Multi-Functional Platforms for Diverse Analyses

A new generation of integrated systems will enable cross-platform use, meaning that the same digested sample may be sent to several instruments to perform simultaneous analysis of multiple analytes such as ICP-MS, IC, UV-Vis, etc. This is not just a way to conserve the volume of samples but also increases the data quality for complete study of the samples.

Summary

The integration of microwave digestion systems with analytical instruments increases efficiency, precision and automation in modern laboratories. The most effective strategies include direct coupling with ICP-MS and ICP-OES. AAS, ion chromatography, robotic automation, etc. As technology advances, more intelligent and more sustainable integration will further revolutionize the workflows for analysis.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.