Laminar flow cabinets are essential in different laboratories as they provide a clean working space to protect sensitive samples from contamination. However, when working with certain hazardous substances, understanding the risks, safety issues, and best practices associated with using a laboratory laminar flow cabinet becomes crucial for minimizing risk and meeting regulatory obligations.

Understanding Laminar Flow Cabinets and Hazardous Materials

Laminar flow cabinets work by controlling airflow through a high-efficiency particulate (HEPA) filter in order to produce an uniform circulation of clean air across the work area. In accordance with the direction of airflow the cabinets are classified as:

- Horizontal Laminar Flow Cabinets: The air is directed through the back of the cabinet to the user.

- Vertical Laminate Flow Cabinets: Air flows through the uppermost part of the cabinet to the lower.

While both types protect samples from airborne contamination only vertical flow cabinets provide a limited level of protection for the operator when paired with the right Front shields as well as exhaust system.

Common Hazardous Materials in Laboratories

Here is a chart listing common hazardous materials that may be found in laboratory environments and the associated risks.

| Category | Examples | Associated Risks |

| Biohazards | Human blood samples | Transmission of disease, infection |

| Volatile Chemicals | Actone, chloroform, formaldehyde | Toxic vapor inhalation, flame and explosion |

| Cytotoxic Drugs | Agents for Chemotherapy (e.g. Doxorubicin) | Carcinogenic, mutagenic and teratogenic adverse effects |

| Radioactive Materials | Iodine-131, Tritium | Radiation exposure, contamination |

| Flammable Solvents | Methanol, ether, ethanol | Fire hazard, explosion risk |

| Allergenic Compounds | Dander from laboratory animals and enzymes | Allergy, respiratory sensitization |

| Nanomaterials | Nano-silver, carbon nanotubes | Unknown toxicological effects Lung penetration |

| Corrosive Substances | Strong acids (HCl HNO3) bases (NaOH) | Chemical burns as well as toxic fumes |

Key Safety Features should be Integrated in Laminar Flow Cabinets for Handling Hazardous Materials

- High-Efficiency HEPA or ULPA Filtration Systems: A top-quality cabinet for laminar flow must have HEPA (High-Efficiency Particulate Air) filters as well as in some more high-end applications ULPA (Ultra-Low Particulate Air) filtering. These filters are vital for capturing harmful particulates and keeping them from recirculating back into the laboratory. HEPA filters are typically able to eliminate 99.97 percent of particles >=0.3 millimeters in diameter and ULPA filters provide even greater effectiveness in filtration.

- Negative Pressure Containment Zones: In the case of hazardous handling of materials The integration of positive pressure zones surrounding the work area is crucial. Contrary to standard laminar flow hoods which work with positive pressure, a negative pressure confinement makes sure that in the event of there is a leak, contamination of the air is pulled backwards which reduces the chance of exposure for employees.

- Front Access Shields or Sashes: A transparent and moveable sash, or shield creates physical barriers between the user and dangerous materials contained within the cabinet. This feature shields users from accidental sprays, aerosols or spills whilst providing clear access to the work area.

- Alarm Systems for Airflow Disruption: Alarms that are both audible and visually triggered that alert workers to disruptions in airflow that result in a reduced velocity or blockage of the filter is essential. Alarms like these ensure that immediate corrective action is carried out to ensure safety in the working setting.

- Chemical-Resistant Interior Surfaces: The cabinet’s interior surfaces must be constructed of chemical-resistant, non-porous materials like the stainless steel and coated composites. They are resistant to corrosion and facilitate an efficient decontamination process, avoiding the accumulation of toxic residues as well as cross-contamination between jobs.

- UV-C Germicidal Lamps (with Safety Interlocks): Although not appropriate for all situations However, UV-C lamps can be employed to disinfect the interior work area when the cabinet is not being used. They should be equipped with interlocks that automatically turn off the light source when the sash is lifted to protect the user from UV radiation.

- Exhaust Integration or External Ducting: To handle volatile chemicals or biohazardous substances The cabinet must be constructed to connect to the outside exhaust systems. This stops the recirculation of dangerous gases into the laboratory, and directs the air contaminated with contaminants safely away from the building via HEPA and carbon-filtered exhaust.

- Ergonomic Design for Safe Operation: Safety also entails minimizing stress and fatigue. Cabinets must have adjustable stands, sashes with an angled front and adequate lighting to encourage proper posture, good visibility and comfortable working conditions. These factors can contribute to a safe, long-lasting environment.

- Integrated Waste Disposal Ports: To make it easier for safe and hygienic disposal of waste, certain cabinets are equipped with sealed waste disposal ports, or containers that are contained within the cabinet. These systems enable immediate confinement and isolation of hazardous wastes without disrupting the safe and sterile airflow conditions.

- Digital Monitoring and Data Logging: Advanced laminar flow cabinets could have control panels with digital technology for continuous monitoring of airflow levels as well as filter performance as well as operational and operating parameters. Data logging allows labs to monitor usage, maintenance and performance trends. This is useful for audits and ensuring safety compliance.

Key Safety Practices in Laminar Flow Cabinets for Handling Hazardous Materials

- Know the Purpose and Limitations of Laminar Flow Cabinets

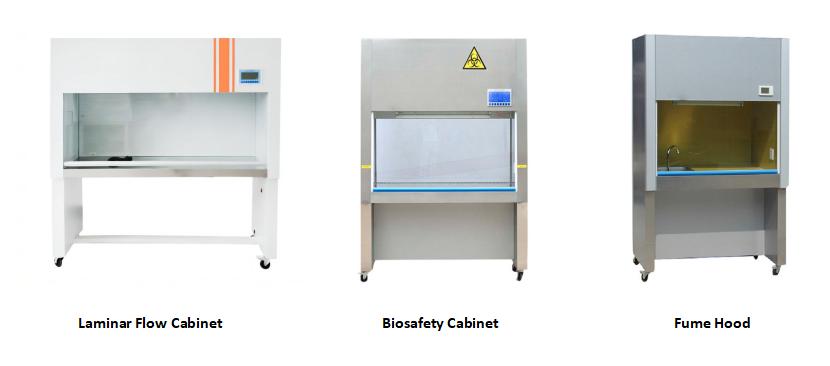

The most important and first security practice is to understand what laminar flow cabinets are and they are not made to accomplish. These cabinets shield the contents of the workplace from contamination but they do not offer protection to users or the surrounding environment from exposure to harmful substances. Therefore, any work involving hazardous chemical or infectious agents might require other containment methods such as chemical fume Hoods.

- Conduct a Thorough Risk Assessment

Before beginning any work an in-depth risk assessment should be carried out. This involves determining the kind of material that is hazardous and the risk of exposure, as well as the potential routes for contamination. Based on this analysis consider whether a laminate flow cabinet is a suitable and secure choice for the process.

- Use Appropriate Personal Protective Equipment (PPE)

Even in an air-filtered environment, PPE remains a frontline protection. Personnel working in laboratories are required to wear lab coats, gloves with safety goggles, and in certain instances wearing face shields or respirators. PPE should be selected according to the type of hazardous substances and the degree of risk.

- Prevent Airflow Disruption

A proper usage of the cabinet is to ensure an unobstructed, smooth airflow. Do not place large objects close to areas of air infiltration or exit zones. Make slow and deliberate moves to reduce the amount of turbulence. Do not block the airflow pattern in order to cause a problem with the sterility of the process and your safety as an worker.

- Limit Items Inside the Cabinet

Only the essential equipment and materials must be stored in the cabinet. The overcrowding of the cabinet not only hinders airflow but also increases chance of cross-contamination and accidents. Utilize clean and sterile equipment and keep the workspace clean and tidy at all times.

- Ensure Effective Waste Disposal

The handling of hazardous materials will always result in garbage, which needs to be handled with diligence. Use leak-proof, clearly labeled containers for chemical or biological waste. Don’t let waste get accumulated in the cabinet. Be sure to follow the rules of the institution or regulatory agency to ensure proper separation and disposal.

- Clean and Decontaminate Regularly

Cleaning regularly is essential in maintaining a secure and clean work surroundings. The work area must be cleaned with the appropriate chemicals prior to and after every use. If necessary the UV-C sterilization method can be utilized even in the event that the cabinet isn’t operating, but it shouldn’t be used to replace manual cleaning methods.

- Maintain the Cabinet Through Regular Servicing

Regular maintenance and the certification of the laminar flow cabinet are essential. HEPA filters must be inspected and replaced if needed and airflow should be tested to make sure it is in compliance with performance standards. A recertification each year by a trained technician can ensure that the unit is suitable for use.

- Follow Standard Operating Procedures (SOPs)

Laboratories should establish and implement specific SOPs to work with hazardous substances inside laminar flow units. They should include the preparation, operation decontamination, waste disposal and emergency response. SOPs should be reviewed frequently and revised based on the latest safety standards.

- Ensure Proper Training for Personnel

Safety protocols are not effective without proper education. Everyone must be educated in the correct way to operate laminar flow cabinet and how to handle dangerous materials in a safe manner. Training should cover practical knowledge as well as theoretical exercises, as well as regular refreshers to reinforce the best methods. The compliance with international standards like NSF/ANSI49, EN ISO 12469 and ISO 14644 ensures that safety and performance standards are achieved.

When to Use Alternatives for Laminar Flow Cabinets in Handling Hazardous Materials

If you are working with hazardous materials, Laminar flow cabinets might not provide adequate protection for the worker or the environment. In such instances it is crucial to look at alternative methods of containment. Knowing when to choose the alternatives is crucial to ensure safety in the laboratory and conformity with biosafety and chemical handling requirements.

When Personnel Protection Is Required

Laminar flow cabinets that are standard in design are designed to safeguard the item only. They are not able to provide protection for the user against harmful aerosols, vapors, as well as infectious substances. If the activity or project is involving substances that could pose health risks by inhalation or exposure, for example pathogens, cytotoxic substances, or volatile chemicals, a cabinet that provides protection for the user like the biosafety cabinets (BSC) as well as a chemical fume hoods, should be utilized.

When Environmental Protection Is Necessary

The handling of materials that be harmful towards the ecosystem, like genetically altered organisms, radioactive substances or biohazards, require an enclosure that blocks the escape of pollutants. Laminar flow cabinets usually employ recirculated air, and don’t filter exhaust properly for these substances, the use of a class II biosafety cabinet or one with a ducted fumehood equipped with appropriate filtering of exhaust is the better option.

When working with volatile toxic Chemicals

Laminar flow cabinets do not work for work involving toxic and volatile chemical or solvents. The airflow of these cabinets may create vapors in the room, creating the risk of inhalation. In these instances an hood for chemical fumes constructed using negative pressure, and direct exhaust is essential to take out dangerous vapors from the work area.

When Using Biohazardous Agents

If you are working with infectious microorganisms such as bacteria, viruses or human-derived substances that fall within Biosafety Level 2 or 3–a biosafety cabinet must be in place. BSCs are specially designed to protect the product the user, as well as the environment by using HEPA-filtered exhaust systems and supply systems, as well as containment features like negative airflow as well as physical barriers.

When HEPA-Filtered Exhaust Is Not Enough

Certain processes produce hazardous gases or particles that can’t be safely contained or neutralized using HEPA filtration on its own (e.g. solvents, acids or anesthetic gasses). In these cases the cabinet needs to be outfitted with carbon filters or external ducting or the process needs to be moved to a fumehood that has adequate filtration and capture capabilities.

When Cross-Contamination Must be Prevented

In situations where several dangerous samples are handled at the same time and the possibility of cross-contamination is very high (e.g. the PCR setup using infectious agents) Laminar flow cabinets may inadvertently release contaminants because of their airflow patterns which are not closed. A biosafety cabinet that has vertical laminar flow and upward airflow, or isolated containment systems can provide better alternatives.

When Working in High-Risk Laboratory Settings

Facilities that operate in accordance with Good Laboratory Practice (GLP) or Biosafety Level 3/4 or handling extremely potent substances could be subject to regulatory requirements that restrict making use of front-facing flow cabinets to perform hazardous tasks. These include glove boxes and Class III BSCs or closed-system isolaters could be required to ensure the greatest amount of protection.

Final Thoughts

Although laminar flow cabinets are vital to creating sterile work environments but their use with potentially hazardous materials requires careful adaptation and stringent safety protocols. Laboratories should critically evaluate the compatibility of these cabinets with particular applications and put aside the appropriate security features and training and operating discipline.

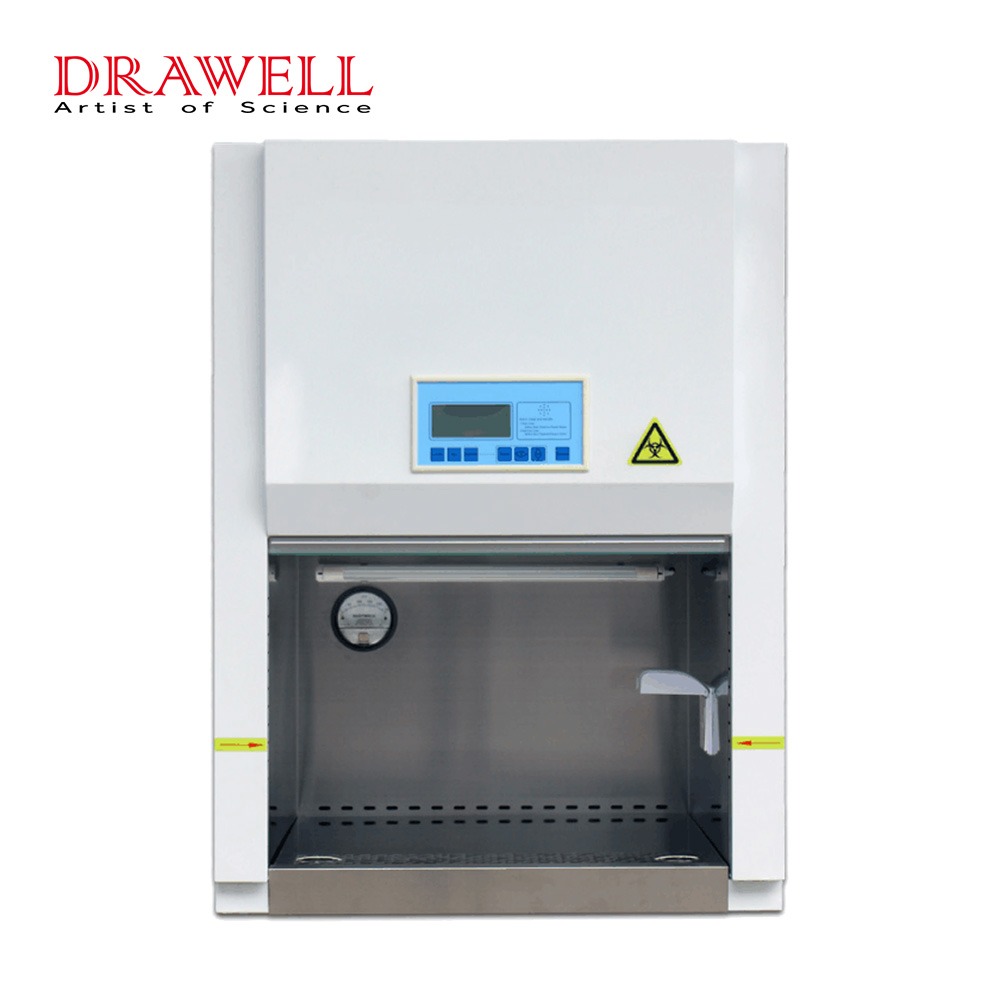

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.