When deciding on a muffle furnace for laboratory or industrial use certain critical aspects are to be considered to ensure that the furnace can meet the requirements of your business. The muffle furnaces are crucial for high-temperature applications like sintering, analysis of ash content as well as calcination, materials testing, etc. With the wide range of muffle furnaces on the market knowing how to select the best one is essential to ensure the efficiency, accuracy as well as safety for your operation.

What is a Muffle Furnace

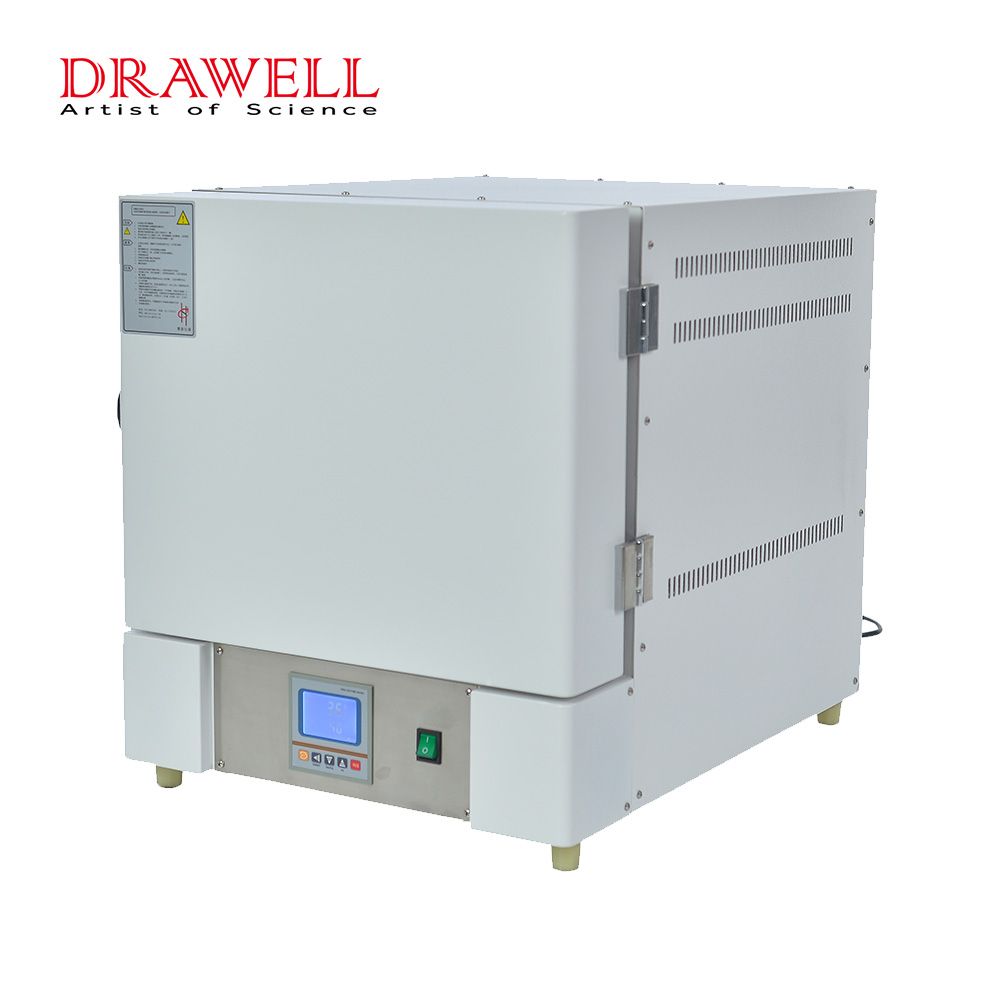

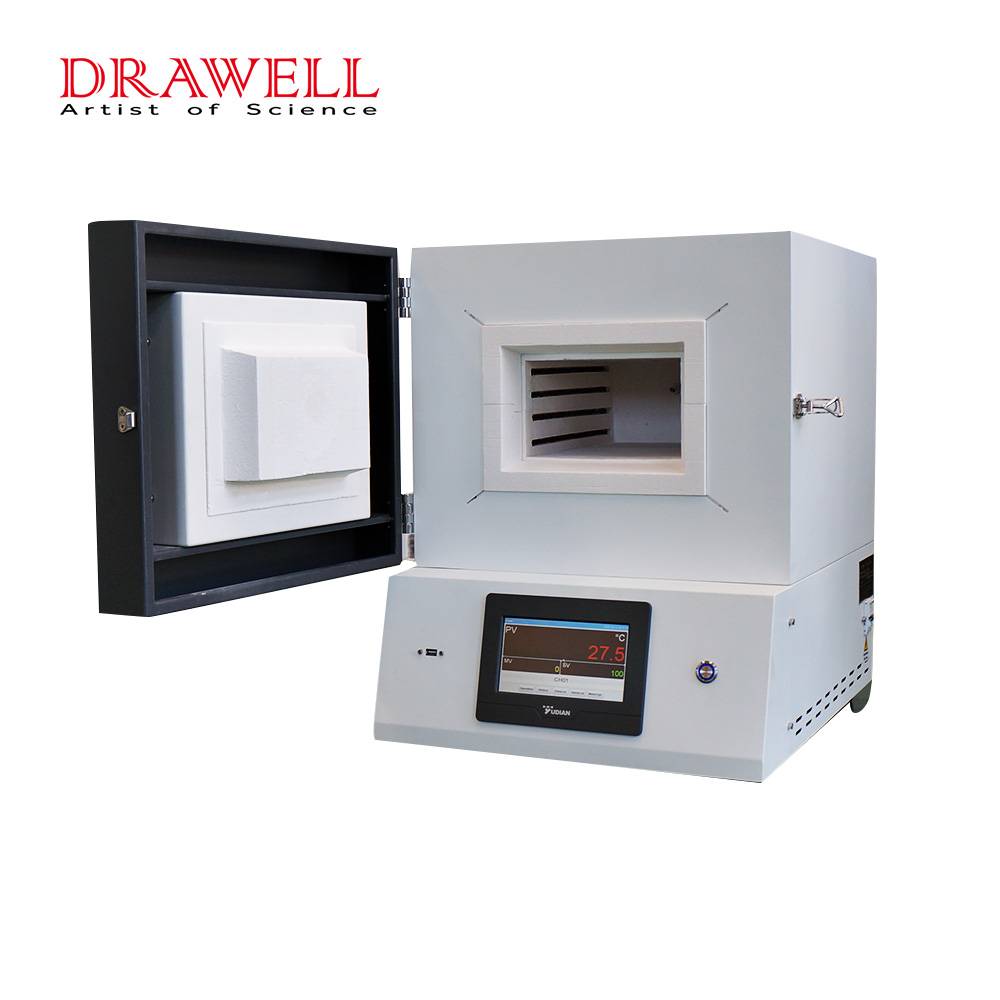

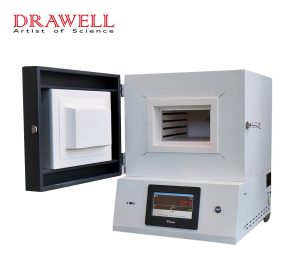

Muffle furnaces are a high temperature heat source that is commonly utilized in industrial and lab settings.It has an enclosed chamber that shields the specimens of direct interaction with heating elements, which ensures an even heat distribution, and also preventing contamination. Muffle furnaces can be used to reach temperatures up to 1800°C according to the model and they are fitted with the latest control systems that can precisely control temperature. They are vital devices for applications that require consistent and controlled heating for a range of industrial and scientific processes.

Common Types of Muffle Furnaces

This chart offers a quick outline of the different kinds of muffle furnaces as well as their common uses, as well as their special features.

| Type of Muffle Furnace | Temperature Range | Heating Element | Insulation Material | Common Applications | Key Features |

| Standard Muffle Furnace | 600°C to 1200°C | Kanthal (FeCrAl alloy) | Ceramic, fiberglass | Testing of general materials, Ashing the calcination | The most economical, widely utilized and suitable for a wide range of applications |

| High-Temperature Muffle Furnace | 1300°C to 1800°C | MoSi2 (Molybdenum Disilicide), Graphite | High-density Ceramic, Insulation Boards | Sintering, advanced testing of materials and refractory material processing | Ideal for applications that require high temperatures. robust insulation |

| Laboratory Muffle Furnace | 500°C to 1100°C | Kanthal or Silicon Carbide | Ceramic Bricks, which are insulating | Laboratories, research, education and research | Compact, precise and easy to use for testing on a small scale |

| Programmable Muffle Furnace | 600°C to 1200°C | Kanthal or MoSi2 | Ceramic High-temperature insulation | Applications and research that require specific heating profiles | Programmable temperature control, ramp/soak capabilities |

| Vacuum Muffle Furnace | 500°C to 1300°C | Kanthal or MoSi2 | Vacuum-tight ceramic liner | Applications that require an inert or vacuum atmosphere, e.g., sintering or an annealing | Reduced oxygenation, protective atmosphere high heat uniformity |

| Rotary Muffle Furnace | 600°C to 1200°C | Kanthal (FeCrAl alloy) | High-temperature insulation | Industrial applications of large scale Continuous processing | Rotating chamber for uniform heating, ideal for bulk materials |

A Step-by-step Guide to Choosing the Right Muffle Furnace for Your Specific Applications

1. Define Your Temperature Requirements

- Maximum Temperature: Muffle furnaces usually vary in temperature ranges from 600°C up to 1800°C or higher. It is the first thing to figure out what temperature that your process requires. When working on common material, then a furnace offering an operating temperature 1000°C could suffice. However, for more extreme applications (e.g. Sintering, sintering or special tests on materials) You may require an oven that can handle temperatures that exceed 1400°C.

- The Accuracy and Precision of the Temperature Control: Be sure that the muffle furnace has precise control over temperature settings. This is done with digital controllers as well as programmable options for soaking and ramping at certain temperatures. A precise control will ensure consistency and repeatability.

2. Consider the Furnace Size and Capacity

- Internal Chamber Dimensions: The chamber’s size will be able to accommodate the material you intend to heat without overburdening the furnace. A larger chamber is ideal the handling of larger or heavier samples, whereas smaller chambers are perfect for smaller, less-intensive testing.

- Capacity for Load: Make sure that the furnace’s capacity for load corresponds to the weight and dimensions of the typical samples. Overloading could compromise performance and shorten the life of the furnace.

3. Choose the Right Heating Elements

- Materials that is used in Heating Elements: Heating elements are made available in various types of materials such as Kanthal (FeCrAl alloy), Molybdenum Disilicide (MoSi2) and graphite. Kanthal is used for general-purpose uses, however MoSi2 and graphite can be used for higher temperatures or areas where a reduced atmospheric condition is there.

- Durability Durability: The endurance of the heating element is essential for their long-term performance. Examine the specifications of the manufacturer for the expected life expectancy of heating elements, since it will affect maintenance costs as well as the downtime of furnaces.

4. Evaluate Temperature Uniformity

- Uniform Heating: The efficiency of a muffle heater is based on its capacity to ensure an uniform temperature distribution throughout the chamber. Uneven temperature distribution could result in uneven results, particularly for applications like material testing or the ashing.

- Features to Improve Uniformity Find: features like forced air circulation or several heating elements that are able to work together to ensure an even distribution of heat. Also, make sure the furnace comes with sophisticated controllers that allow you to fine tune the temperature profiles.

5. Look for Advanced Control and Monitoring Features

- Digital Temperature Control: Pick the muffle furnace with an electronic controller that provides simple to read settings, which allow for precise control over temperature as well as time. Digital controllers should have the programmability of settings to streamline processes and increase repeatability.

- Over-temperature Safety: Overheating can cause irreparable damage both to the furnace as well as the materials within. Check that your furnace has built-in protection against temperature overheating as well as an auto shut off function to stop accidents from happening.

6. Assess Insulation and Energy Efficiency

- Qualitative Insulation: The insulation substance used inside the furnace can be vital to energy efficiency and ensuring temperatures stable. Good insulation is able to reduce heat loss and decreases the energy usage, while also keeping operating costs to a minimum.

- Energy Efficiency: Find features that save energy, such as high-efficiency heating elements as well as thermal insulation that reduces the use of energy. Certain furnaces are built to run in energy-saving modes which could help cut operating costs.

7. Safety Features

- External Casing: Make sure the furnace is adequately protected at the exterior. This is especially important in industrial or laboratory settings in which safety is a important consideration. A well-insulated outer casing will help to prevent burns caused by accidental contact.

- Ventilation and Extraction of Fumes: Certain materials emit fumes when heated. These could pose a risk. Check if the furnace comes with a built-in exhaust system, or the need to join it with an external system for fume extraction to manage toxic gases in a safe manner.

8. Material Compatibility

- Internal Lining: The material that is used to make the furnace’s interior lining must match the material that are being heated. Refractory ceramic, silica and alumina are often employed due to their resistance to temperatures up to 300°C. Some furnaces provide lined for reactive or corrosive materials.

- Resilience to Corrosion: When working with chemicals or other materials that create corrosive by-products make sure that the furnace’s interior is resistant to corrosion or you could consider adding additional lined with a protective coating.

9. Maintenance and Durability

- Easy Maintenance: Select one that is easy to maintain and clean. Regular maintenance prolongs the life of the furnace and guarantees the same performance. Choose units that have easy-to-replace heating elements as well as easily accessible parts.

- Durability: Check the warranty and service support provided by the maker. A longer warranty usually suggests better quality of construction, and having access to top-quality customer support is vital for repairing and troubleshooting.

10. Budget and Long-Term Value

- Initial Cost in comparison vs. Long-term investment: Although it is tempting to select the cheapest muffle furnace, take into account the long-term expenses. A less expensive furnace could incur more energy and maintenance costs in the long run. The best furnaces, though costlier initially, can provide better efficiency, longer-lasting and lower operating expenses in the long term.

- Total Cost of Ownership Review: your total costs of ownership which includes maintenance, energy consumption and any other equipment (such as control systems or ventilation systems). Include these costs in your decision-making procedure.

11. Consider Manufacturer Reputation and Support

- Brand Reputation: Select a furnace from an reputable and trusted manufacturer. Brands with a proven track record typically offer more reliable products as well as better customer service.

- Customer Support and Warranty: Before you make your final decision, be sure to verify the warranty offered by the manufacturer as well as the availability of support for customers. A reliable support system is vital to troubleshooting, maintenance and repair.

Selecting the Right Muffle Furnace with Drawell

Drawell is a reputed manufacturer of top-quality muffle furnaces that provide reliable and effective solutions for a broad range of laboratory and industrial applications. They are known for their robust construction, sophisticated technology for temperature control, as well as efficient designs, muffle furnaces manufactured by Drawell will ensure accurate heating and top performance. In addition to top-quality equipment, Drawell offers excellent client assistance and a comprehensive warranty.

Selecting the best muffle furnace is about understanding the specific requirements of your business, such as the temperature range required chamber size, chamber dimensions and heating elements safety features, materials compatibility, and so on. When you carefully consider these elements to select the right muffle furnace to give you reliable performance, consistent results, and long-term reliability for the applications you have. Be sure to weigh the initial expense against the benefits over time such as energy savings and durability, in order to make a well-informed decision that can improve the efficiency and security of your business operations. If you need help of choosing muffle furnace, feel free to contact Drawell.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.