Metal analysis of heavy metals is essential in monitoring the environment and food security as well as pharmaceutical quality control as well as industrial hygiene. One of the most crucial steps to ensure precise measurement of trace metals is preparation. These systems of digestion have become the preferred method for making samples ready for analysis. They offer increased efficiency, safety and accuracy when compared with conventional digestion techniques. This article examines the ways that microwave digestion systems function in their favor, as well as their use in the analysis of heavy metals.

Challenges in Heavy Metal Analysis

| Challenge | Description | Impact on Results |

| Matrix Complexity | There is a presence of organic and organic interferences in sample matrices. | It can suppress or boost signals which can lead to mistakes. |

| Sample Preparation Errors | Incomplete digestion or contamination during handling. | Causes inaccurate or unproven results. |

| Volatile Element Loss | The loss of elements such as arsenic or mercury during an open digestion. | Overestimation of the concentrations of heavy metals. |

| Detection Limit Requirements | It is essential to measure metals at trace and ultra-trace levels. | Needs extremely sensitive and accurate systems that are extremely sensitive and calibrated. |

| Cross-Contamination | Contaminants in labware, reagents or the environmental factors. | Causes false positives or data that is inconsistent. |

| Calibration and Standardization | Variability in accuracy of calibration curves and the standards employed. | It affects the reliability and comparison of results. |

| Instrument Drift and Interference | The signal drift and noise are common in instruments for detection such as ICP MS or AAS. | Reduces accuracy and reduces confidence in analytical analysis. |

| Regulatory Compliance | Conformity to various internationally recognized standard (e.g., EPA, FDA, ICH). | Needs to be consistent in documentation and has to be accurate. |

| Sample Throughput Demands | Fast turnaround is required for labs with high volumes of testing. | It slows down workflows when |

How Microwave Digestion Systems Work for Heavy Metal Analysis

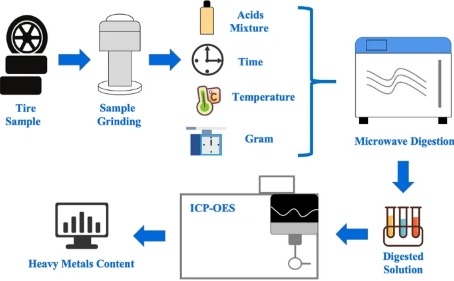

Detecting trace metals like lead, mercury, arsenic, and cadmium requires more than just advanced instrumentation–effective sample preparation is critical. The most efficient and extensively used methods for preparing samples involves microwave digestion. This technique has changed the way labs handle difficult and complex matrices. It guarantees reliable results even at the trace level.

The Need for Effective Sample Preparation

Before a sample is examined using methods like ICP-MS (Inductively Coupled Plasma Mass Spectrometry), ICP-OES, ICP or AAS It has to be disintegrated into a clean homogenous liquid. The process removes organic matter and disintegrates metals into a solution that is suitable for accurate quantification. Traditional digestion methods, such as open-vessel acid digestion are slow and risk contamination, and can cause losing volatile components. Microwave digestion systems address these problems by providing an easier, more efficient and safer method for the preparation of a broad range of samples.

How Does Microwave Digestion Work?

Microwave digestion relies on the application of microwave energy to heat acid mixtures inside sealed, high-pressure-resistant vessels. These vessels are usually made of chemically inert materials such as PTFE (Teflon)–hold your sample as well as acids in a sealed space. When microwaves enter into the vessel, they trigger the molecules of acid and water and cause rapid even heating.

The sealed environment permits temperatures that exceed 200 degrees Celsius and pressures to exceed the limits of atmospheric pressure, greatly increasing the efficiency of breaking down even the most tough samples matrixes. High-pressure control and high temperature conditions boost the chemical reactions between acids and the material, resulting in total digestion.

Key Working Steps

- Sample and the Addition of Reagents: A small portion from the specimen is put into a digester vessel which is then and then adding concentrated acids like hydrochloric acid, nitric acids or hydrogen peroxide based on the type of sample.

- Sealing the Vessel: The vessel is sealed to protect against the building up of pressure and heat in the process of digestion.

- The Microwave Heating Cycle: The sealed vessel is put within the microwave digestion unit. The system then executes an controlled microwave program heating the samples and acids to a certain temperature and pressure that is based on the digestion method chosen.

- The Cooling Phase after the Digestion Process: The system is then permitted to cool. The pressure is then let go and the digested solution is now ready to be analysed.

- Post-digestion Handling: The resultant clear liquid is then diluted as necessary and transferred to instruments for the determination of heavy metals.

Advantages of Microwave Digestion Systems for Heavy Metal Analysis

- Enhanced Digestion Efficiency

One of the biggest benefits that microwave digestion has is the capacity to completely break down complicated samples matrices. By using sealed, pressure-resistant vessels as well as monitored microwave power, the method creates high pressures and temperatures that allow full digestion of the samples, including soil plants, plant material, biomaterials and plastics. This guarantees that the metallic heavy elements are released into the solution which improves the accuracy of the subsequent analysis.

- Retention of Volatile Elements

The open-vessel digestion process can result in the removal of heavy metals that are volatile such as arsenic and mercury because of evaporate. Microwave digestion on the contrary, takes place in closed systems which block the evaporation of volatile substances. This leads to higher rates of recovery and more precise quantification of analytes that are sensitive.

- Time-Saving and High Throughput

Microwave digestion dramatically cuts down on the time needed to prepare samples. Traditional hotplate digestion may take hours to complete, whereas microwave digestion usually can be completed within 20 to 60 minutes. Furthermore, modern technology allows simultaneous digestion of several samples, which increases the speed of lab operation and efficiency.

- Improved Reproducibility and Consistency

The automated control of temperature and pressure in microwave digestion assures consistent conditions throughout every vessel. This ensures high-quality results that are crucial in highly controlled areas like manufacturing pharmaceuticals as well as tests for environmental compliance.

- Reduced Contamination Risk

The closed-vessel design reduces the risk of contamination from outside, which is one of the most common problems in the analysis of trace metals. Since the samples are kept in a sealed container during the digestion process, there is no chance of interference from the environment that can lead to clean blanks as well as more reliable data.

- Lower Acid Consumption and Waste Generation

Microwave digestion uses smaller amounts of concentrated acids than traditional methods. This reduces the costs of reagents but also lowers harmful waste generation, contributing to safer working environments and increased sustainability of the environment.

- Versatility Across Sample Types

Microwave digestion systems can be adapted to a broad range of different types of samples, ranging including solid samples of environmental, to high-fat foods and pharmaceutical formulations. This flexibility is a great advantage for labs that perform a variety of analytical tasks.

Applications Across Industries of Microwave Digestion Systems for Heavy Metal Analysis

| Industry | Application | Purpose of Heavy Metal Analysis |

| Environmental | The soil and water as well as air particulate samples digestion | Monitoring pollution and ensuring compliance with the environmental regulations |

| Food & Agriculture | Testing of crop animals feed, processed food products, and beverages | Food safety, and testing the food for contaminants (e.g. lead and Cadmium) |

| Pharmaceutical | Analyzing intermediates, raw materials, and final drug products | Meeting pharmacopeial standards (e.g., USP <232>, ICH Q3D) |

| Mining & Metallurgy | Digestion of concentrates, ores and tailings | Calculating the metal content of the material for value and processing effectiveness |

| Cosmetics | Dissolution of creams, powders and products for personal care | Ensure that products are free of toxic metals such as lead and mercury |

| Petrochemical | Tests of crude oils, lubricants and other residues | Recognizing trace metals that could impact refining processes |

| Clinical/Medical | Analyzing biological samples (blood tissue, urine, and so on) | The monitoring of exposure by patients to toxic metals |

| Electronics | Testing of circuit boards, semiconductor materials and batteries | Assuring the quality of products and safety in compliance |

| Waste Management | Digestion of E-waste and hazardous samples | The determination of toxic metal concentrations is essential for the proper recycling or disposal |

| Construction Materials | Cement, fly ash as well as concrete samples digestion | Evaluation of contamination and material selection |

Key Considerations for Effective Use of Microwave Digestion Systems in Heavy Metal Analysis

Microwave digestion systems are now indispensable instruments in laboratories carrying out analyses of heavy metals. To maximize their full potential, researchers must be attentive to various operational and methodological aspects. The proper application of the method ensures a full digestion, uniform result, and also the reliability of quantification of trace metals at the trace level.

- Selection of Appropriate Reagents

The right acid mix is vital. Nitric acid is used extensively because of its oxidizing capabilities and capability to dissolve many metals. For samples that have a high organic levels, hydrogen peroxide could be added to increase the oxidation process. In silicate-rich samples or those with refractory properties hydrofluoric acid may be required, however it should be handled with extreme care. The amount and type of acids need to be adjusted according to the specific matrix of the sample in order to ensure complete digestion, without compromising the integrity of the vessel.

- Understanding Sample Characteristics

Different types of samples, such as biological tissue, soil food, polymers, or soil–require different digestion strategies. The organic weight, matrix complexity, and possible metal content can impact digestion time temperatures, digestion settings, and acid mixtures. It is crucial to know the physical and chemical characteristics of the sample in order to optimize the digestion process.

- Vessel Selection and Maintenance

The microwave digestion vessel is generally constructed from materials such as quartz or PTFE, which are able to withstand extreme temperature and chemically impervious. The user should make sure that the vessels are in good condition, unharmed and properly sealed prior to using. Regular inspections and maintenance are crucial to prevent cross-contamination and leaks from pressure and both can compromise the analytical results.

- Temperature and Pressure Control

Effective digestion requires accurate temperature and pressure controls. Microwave systems equipped with time-based sensors and feedback loops provide constant and repeatable conditions. Overheating may cause damage to vessels or samples, while under-heating can cause incomplete digestion. Following manufacturer-recommended protocols or validated methods is essential to avoid variability.

Master Ultra High Throughput Closed Microwave Digestion-Extration Workstation

- Avoiding Contamination

Because heavy metal analysis typically concentrates on ultra-trace or trace levels, ensuring that contamination is controlled is essential. All reagents must be analytical grade or better. Utilizing cleanroom techniques such as ultrapure water, ultrapure water, or acid-washed containers is suggested. Even minor environmental contaminants can create significant errors when using sensitive detection methods like ICP-MS.

- Sample Amount and Digestion Load

The ratio between acid and sample should be in line with the requirements for effective digestion and security. The vessel’s load can result in a slow digestion process or an excessive internal pressure. Follow the manufacturer’s guidelines regarding maximum weights for samples helps to ensure that the vessel is operating in a safe manner and helps ensure an efficient break down in the samples.

- Method Validation and Reproducibility

Each laboratory should test their digestion techniques to ensure that they’re suitable for the specific sample and analytes. This includes confirming the recovery rate of standardized methods, examining the blanks, and checking for the consistency of batches. The reproducibility of digestion directly impacts the quality of quantification of heavy metals.

- Post-Digestion Handling

After digestion is completed After that, careful treatment of digest mixture is required. Transferring the digest to clean containers and then diluting it prior to analysis will help keep it from being lost and secondary contamination. It is also essential to allow adequate cooling time to relieve the build-up pressure prior to vessel opening.

Final Thoughts

The development of microwave digestion systems has revolutionized the process of preparing samples for analysis of heavy metals and offer unbeatable speed, precision and security. Their capability to handle diverse matrixes makes them suitable for laboratories that require exact measurements of trace metals.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.