In the bustling world of chemical analysis, time is often a precious commodity, and the reliability of results is paramount. For decades, the determination of a substance’s melting point has been a fundamental technique for assessing purity and identifying compounds. However, traditional methods, often relying on visual observation through heated oil baths or simple block heaters, can be both time-consuming and prone to subjective interpretation. This article delves into the transformative impact of precision melting point apparatuses, showcasing how their advanced technology not only accelerates the analysis process but also significantly enhances the accuracy and reproducibility of melting point determinations, ultimately revolutionizing laboratory workflows.

The Challenges of Traditional Melting Point Determination

Traditional methods for determining melting points, while historically significant, present a number of inherent challenges that can impact both the efficiency and accuracy of the analysis. These methods typically involve placing a small amount of sample in a capillary tube and observing its behavior as it is gradually heated. Whether using a Thiele tube filled with oil or a basic heating block, the process often relies heavily on the analyst’s visual acuity and timing skills.

One of the primary limitations of traditional methods is the subjectivity of visual observation. Different analysts may interpret the onset and completion of melting at slightly different points, leading to variability in reported melting point ranges. This subjectivity is further compounded by factors such as the rate of heating, the lighting conditions, and the observer’s experience. Moreover, maintaining a consistent and controlled heating rate with manual methods can be difficult, potentially leading to inaccurate results. The process can also be time-consuming, especially when dealing with substances that melt over a broad temperature range, requiring slow and careful heating. Furthermore, recording and documenting the melting point often involves manual transcription, increasing the risk of errors. Consider a scenario where multiple samples need to be analyzed daily; the cumulative time spent on these manual determinations can become a significant bottleneck in laboratory productivity. For instance, analyzing just ten samples using a traditional method might easily consume an hour or more, with the potential for inter-operator variability of ±1−2∘C. These limitations underscore the need for more precise and automated techniques.

How a Precision Melting Point Apparatus Works

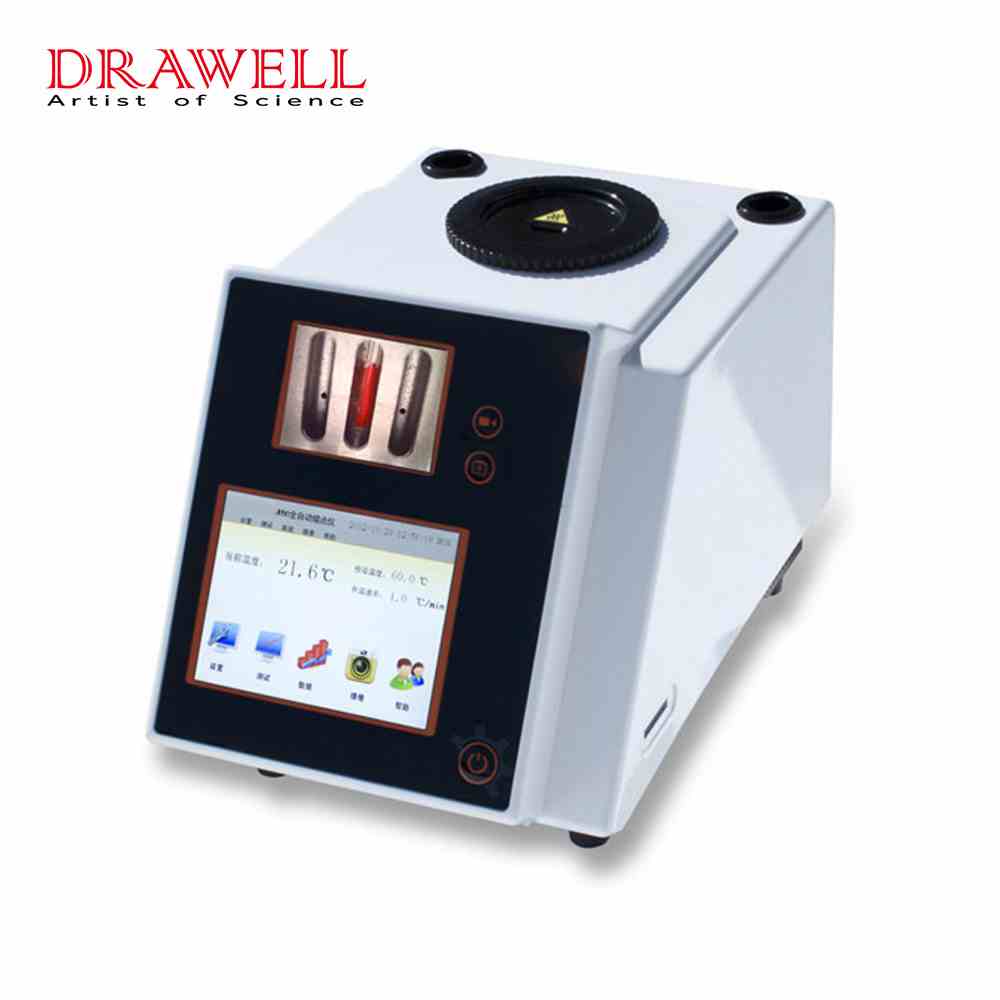

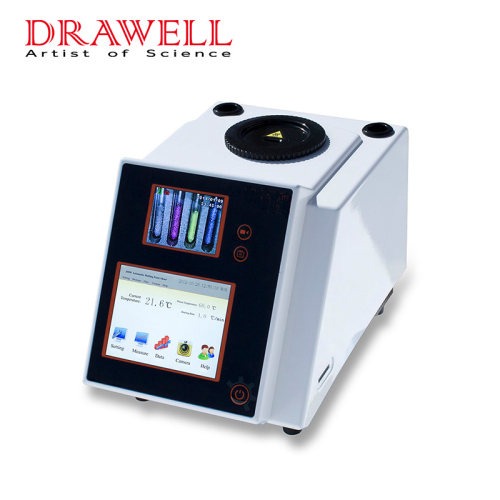

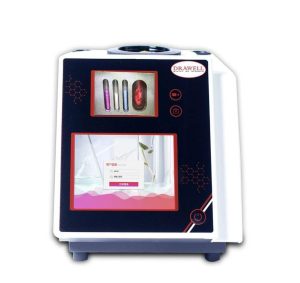

Precision melting point apparatuses overcome the limitations of traditional methods by employing advanced technology to automate and standardize the melting point determination process. These instruments typically consist of a precisely controlled heating block or furnace, a sophisticated optical detection system, and an integrated control unit with a digital display and often software connectivity.

Working Principle

The fundamental principle behind a precision melting point apparatus remains the observation of a substance transitioning from a solid to a liquid state upon heating. However, instead of relying on the human eye, these instruments utilize photodiodes or other optical sensors to detect changes in the sample’s transparency or reflectivity as it melts. The sample, contained in a capillary tube, is placed in the heating block, and a programmed temperature gradient is applied. As the temperature increases, the optical sensor continuously monitors the light passing through or reflected by the sample. When the sample starts to melt, the change in its optical properties (e.g., becoming more translucent) is detected by the sensor, and the corresponding temperature is recorded. Similarly, the point at which the entire sample has melted is also precisely identified and recorded. The instrument’s microprocessor controls the heating rate with high accuracy, ensuring reproducibility between analyses. Many modern instruments also incorporate digital imaging capabilities, allowing for real-time visualization of the melting process on a display and even recording videos for later review.

How Precision Melting Point Apparatus Saves Time

Precision melting point apparatuses are engineered to streamline and automate the melting point determination process, leading to significant time savings in laboratory workflows. Below are detailed explanations of how these devices achieve efficiency:

Automated Processes

- Hands-Free Operation: Precision melting point apparatuses automate sample heating, monitoring, and result calculation. Operators simply load the sample, set parameters, and start the process, freeing time for other tasks.

- Elimination of Manual Observation: Traditional methods require operators to watch samples closely during heating. Automation removes this requirement, saving hours in multi-sample testing scenarios.

Faster Sample Throughput

- Simultaneous Multi-Sample Analysis: Many modern devices allow batch analysis, where multiple samples can be tested in parallel. This capability is especially beneficial in high-throughput laboratories.

- Rapid Heating and Cooling Cycles: Advanced systems feature precise temperature control, enabling faster transitions between test cycles without sacrificing accuracy.

Digital Data Management

- Instant Results: Digital readouts provide real-time results, eliminating delays associated with manual calculations.

- Integrated Documentation: Results are automatically stored in digital formats, reducing the time needed for data logging and analysis.

Compared with traditional method, here are it’s features:

| Feature | Traditional Method | Precision Melting Point Apparatus |

| Sample Handling | One sample at a time | Multiple samples simultaneously |

| Heating Process | Manual control | Automated, precise control |

| Operator Involvement | Constant observation | Minimal, only initial setup |

In a pharmaceutical lab testing the purity of raw materials, switching to a precision melting point apparatus reduced the time spent per sample from 15 minutes to 5 minutes. Over a week, this saved nearly 20 hours of operator time, allowing the lab to test 40% more samples.

How It Improves Results

Precision melting point apparatuses deliver highly reliable and reproducible results, addressing the limitations of traditional methods. The improvements stem from advancements in accuracy, consistency, and data management.

Enhanced Accuracy

- High-Resolution Sensors: These devices feature advanced temperature sensors that detect phase transitions with pinpoint accuracy, often to within 0.1°C.

- Uniform Heating: Precision heating systems ensure consistent temperature distribution, minimizing deviations caused by hot or cold spots.

Reproducibility

- Automated Measurements: Automated detection eliminates human variability in observing melting points, ensuring consistent results across different operators and runs.

- Standardized Procedures: Built-in programs allow labs to follow uniform testing protocols, further enhancing reproducibility.

Comprehensive Data Analysis

- Visual Documentation: Some devices include high-resolution cameras to capture the melting process, providing visual evidence alongside numeric results.

- Digital Records: Data storage and software integration allow for detailed analysis and easier sharing for regulatory compliance.

Improved Quality Assurance

- Error Reduction: Automation eliminates errors caused by subjective observation or miscalculations.

- Reliable Quality Control: High precision and reproducibility ensure that batches meet strict quality standards, critical in industries like pharmaceuticals and chemicals.

Compared with traditional method, here are it’s advantages:

| Parameter | Traditional Method | Precision Apparatus Advantage |

| Temperature Accuracy | ±1°C | ±0.1°C |

| Result Variability | High (operator-dependent) | Low (automation ensures consistency) |

| Repeatability Across Tests | Difficult to achieve | Consistently reproducible |

A chemical manufacturer using a precision melting point apparatus achieved a 30% reduction in rejected batches due to inconsistent purity tests. By ensuring more accurate and reproducible results, the company saved significant costs on reprocessing and improved its overall product quality.

Choose the Right Melting Point Apparatus

Selecting the right precision melting point apparatus is a critical decision that depends on your laboratory’s specific needs and operational requirements. With a variety of models available, understanding the key features to prioritize can help you make an informed choice.

Key Features to Look For in a Precision Melting Point Apparatus

- Temperature Range and Accuracy: Ensure the device supports the temperature range required for your applications. Look for accuracy specifications, typically within ±0.1°C, to guarantee reliable results.

- Automation and Ease of Use: Devices with intuitive interfaces and automated processes reduce operator involvement and training time. Features like automatic detection of phase transitions save time and minimize human error.

- Sample Throughput Capacity: For high-volume labs, a model that accommodates multiple samples simultaneously can significantly boost efficiency. Single-sample units may suffice for research-focused or low-volume settings.

- Data Management and Integration: Choose an apparatus with built-in data storage or the ability to connect to Laboratory Information Management Systems (LIMS). Digital recordkeeping is essential for regulatory compliance and streamlined data sharing.

- Durability and Maintenance: Invest in a robust device with minimal maintenance requirements. Consider models with warranties or technical support to ensure uninterrupted operations.

Additional Features

- Visual Documentation: Cameras that capture the melting process can provide supplementary data.

- Customizable Programs: Pre-set or user-defined protocols for specific testing needs.

- Compact Design: Space-saving designs are beneficial for labs with limited workspace.

Making the Right Choice

When evaluating models, consider creating a checklist based on the features mentioned above. Match these with your lab’s workflow demands, budget constraints, and future scalability requirements. For example, a pharmaceutical lab conducting routine quality control might prioritize high throughput and regulatory compliance, while a research lab might value customization and precision over speed.

By investing in a high-quality precision melting point apparatus tailored to your needs, you can significantly enhance the efficiency and reliability of your analyses. This ensures that your lab remains at the forefront of scientific innovation while meeting stringent quality standards. For any needs of melting point apparatus, please feel free to contact Drawell.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.