In various industries, from food processing to pharmaceuticals, oils play a crucial role. Understanding the chemical composition, purity, and stability of oils is crucial for ensuring product quality, performance, and safety. Among the array of analytical tools available, melting point meters stand out as indispensable instruments for precise and reliable oil analysis. In this article, we delve into the significance of melting point meters in the context of oil analysis, exploring their applications, advantages, and choosing considerations.

Understanding Melting Point Meter in Oil Analysis

The melting point refers to the temperature at which a solid oil transitions into a liquid state. This seemingly simple parameter holds significant meaning for understanding an oil’s characteristics. For instance, in edible oils, a high melting point indicates a higher content of saturated fats, impacting their cooking behavior and shelf life. Similarly, in lubricants, the melting point influences flow properties at different temperatures, affecting their effectiveness in various applications. Deviations from the expected melting point can signal potential issues like contamination, incorrect composition, or storage-related changes, highlighting the importance of accurate measurement.

What is Oil Analysis?

Oil analysis involves the systematic examination of oil samples to determine their physical and chemical properties. This process provides valuable insights into the composition, quality, and condition of oils, enabling informed decision-making in various industrial processes. Key parameters analyzed in oil analysis include viscosity, acidity, moisture content, and most notably, melting point.

What are the Melting Point Meters?

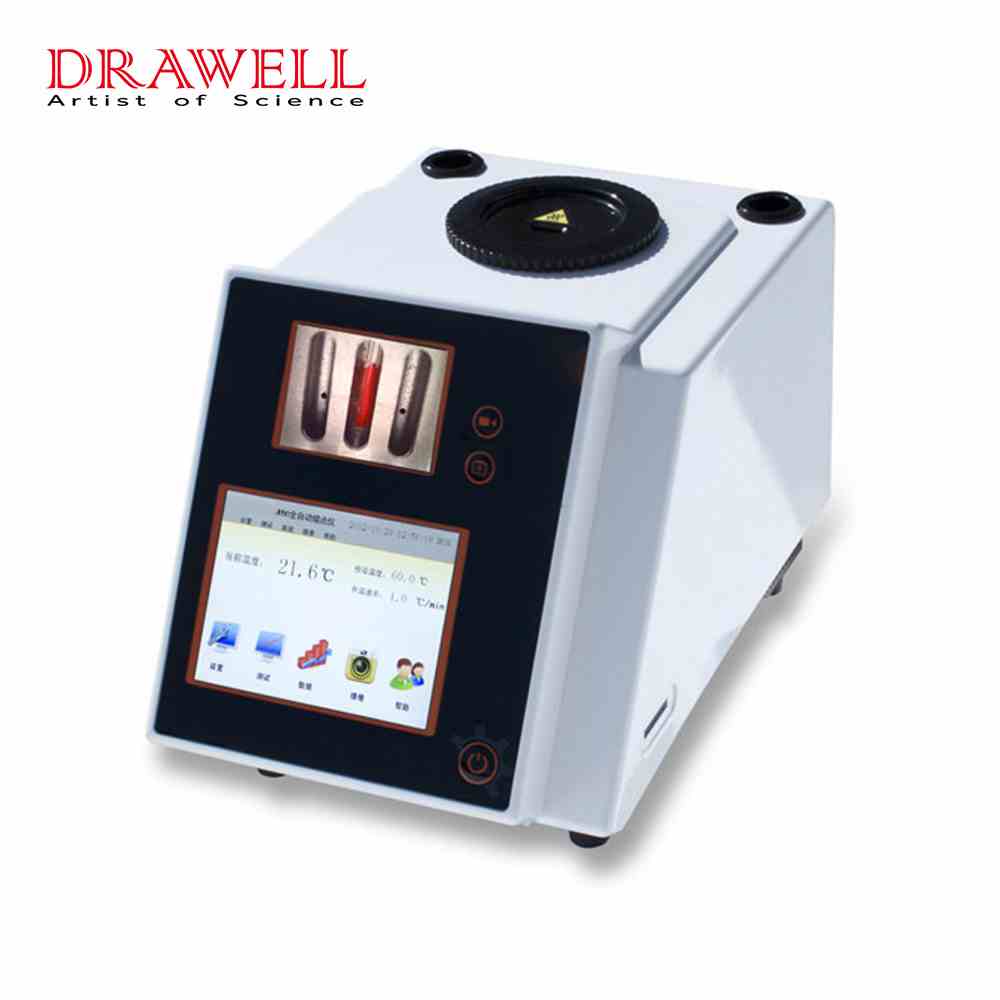

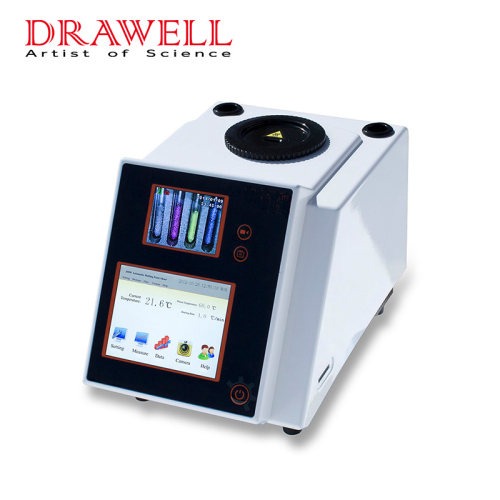

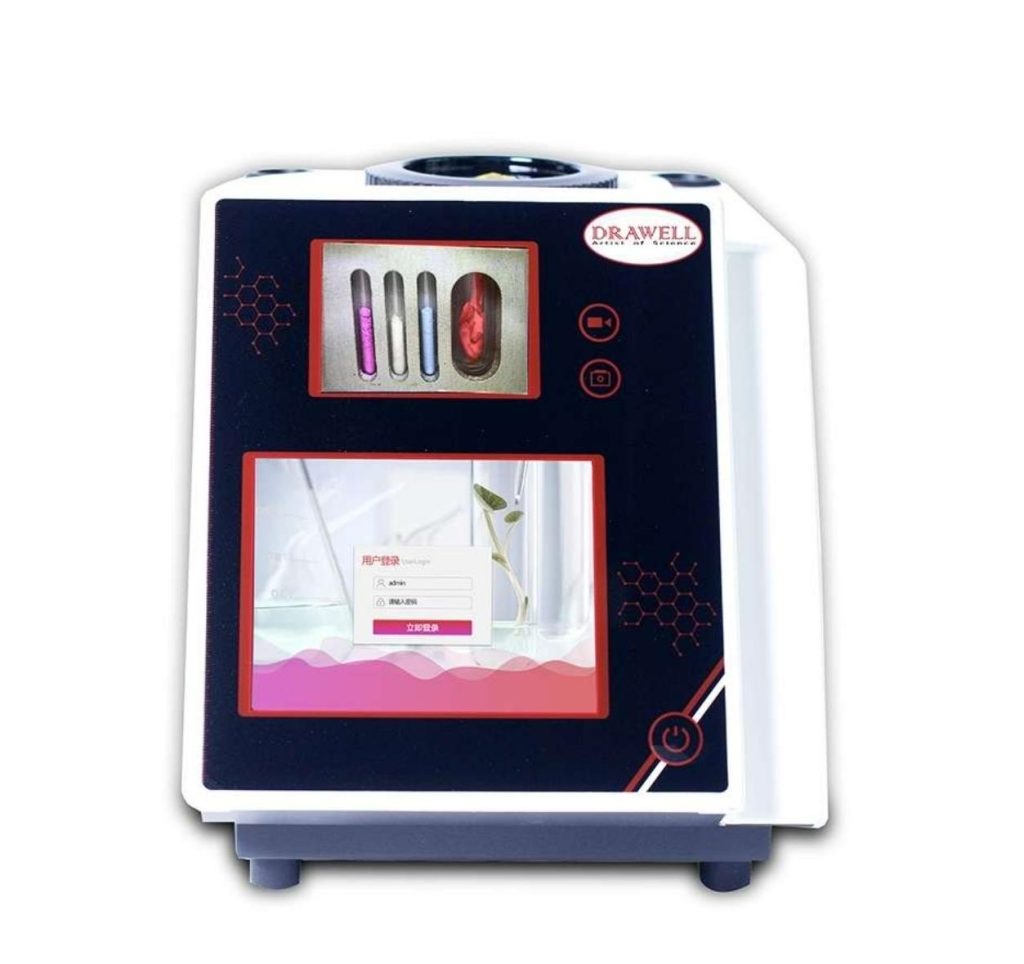

Melting point meters are specialized instruments designed to measure the temperature at which a solid substance transitions into a liquid state. In the realm of oil analysis, melting point meters are utilized to determine the melting point of substances such as fats, waxes, and polymers present in oils. This data offers critical information about the purity, composition, and crystalline structure of oil samples, aiding in quality control and product development efforts.

What are the Types of Melting Point Meters Used in Oil Analysis?

Melting point meters used in oil analysis typically fall into two main categories: traditional melting point apparatus and modern automated melting point instruments. Here’s a brief overview of each type:

Traditional Melting Point Apparatus:

- Capillary Tube Method: This method involves filling a capillary tube with the oil sample and then gradually heating it until the substance melts. The temperature at which melting occurs is recorded manually.

- Hot Stage Microscopy: In this method, a small amount of the oil sample is placed on a hot stage microscope equipped with a heating element. The sample is observed under a microscope while being heated, and the temperature at which melting begins is noted.

Modern Automated Melting Point Instruments:

- Differential Scanning Calorimetry (DSC): DSC instruments measure the heat flow into or out of a sample as it is heated or cooled, providing information about phase transitions, including melting points. These instruments offer high precision and accuracy.

- Automated Melting Point Apparatus: These instruments automate the process of heating and cooling oil samples and recording melting point data. They often feature digital displays, programmable settings, and data storage capabilities for enhanced efficiency and reproducibility.

- Infrared (IR) Spectroscopy: While primarily used for chemical analysis, IR spectroscopy can also be employed to determine melting points indirectly by observing changes in the infrared spectrum of a sample as it undergoes phase transitions.

The choice of melting point meter depends on factors such as the type of oil being analyzed, the required precision and accuracy of measurements, the throughput of samples, and the available budget.

Importance of Melting Point Meters in Oil Analysis

The importance of melting point meters in oil analysis cannot be overstated. These instruments play a multifaceted role in the industry, contributing to various aspects of oil characterization and assessment:

- Quality Assessment: Melting point meters provide precise measurements of the temperature at which solid components within oils transition to a liquid state. This data helps assess the purity and quality of oils, ensuring they meet industry standards and regulatory requirements.

- Identification of Impurities: By analyzing the melting points of various components within oils, melting point meters can identify impurities or contaminants present in the samples. This capability enables technicians to detect any deviations from expected compositions, facilitating early intervention and corrective measures.

- Monitoring Stability: Changes in the melting points of oil components can indicate alterations in the chemical composition or stability of the oil. Melting point meters allow for the continuous monitoring of these properties, helping to prevent degradation and ensure product stability over time.

- Formulation Optimization: In the development of new oil formulations or the improvement of existing ones, melting point meters play a crucial role. They aid researchers and engineers in optimizing the composition and characteristics of oils to meet specific performance requirements, such as viscosity, consistency, and thermal stability.

- Process Control: Melting point meters contribute to process control by providing real-time data on the melting behavior of oils during production and refining processes. This information enables operators to adjust parameters and maintain consistent product quality throughout manufacturing operations.

- Research and Development: Melting point meters are valuable tools for research and development activities within the oil industry. They allow scientists to investigate the effects of different additives, processing methods, and environmental conditions on the melting properties of oils, leading to the development of innovative products and processes.

- Compliance with Standards: Many regulatory bodies and industry organizations establish standards and guidelines for the quality and composition of oils. Melting point meters assist in ensuring compliance with these standards by providing accurate measurements of critical parameters related to oil composition and purity.

- Cost Savings: By enabling early detection of quality issues and process deviations, melting point meters help prevent costly product recalls, rejections, and production delays. Investing in quality control measures, such as melting point analysis, ultimately leads to cost savings and improved profitability for oil manufacturers and suppliers.

In conclusion, the use of melting point meters in oil analysis offers numerous advantages, including quality assessment, impurity identification, stability monitoring, formulation optimization, process control, research and development support, compliance with standards, and cost savings. These benefits make melting point meters indispensable tools for ensuring the quality, integrity, and performance of oils in various applications across the oil industry.

Applications of Melting Point Meters in Oil Analysis

The versatility of melting point meters makes them applicable across a wide range of industries that rely on oils:

- Food processing: Analyzing fats and oils for desired consistency and melting behavior in baking, confectionery, and frying applications.

- Lubricant manufacturing: Ensuring proper viscosity of lubricants at various operating temperatures for optimal engine and machinery performance.

- Pharmaceutical industry: Maintaining the quality of raw materials like waxes and fats used in various formulations.

- Biofuel production: Monitoring the wax content in biofuels to prevent clogging and ensure smooth operation of engines.

- Other industrial applications: Analyzing oils used in the production of cosmetics, paints, resins, and other products where specific melting properties are crucial.

In summary, melting point meters play diverse and critical roles in oil analysis, contributing to quality control, research and development, and regulatory compliance across various industries reliant on oils and petroleum products. Their ability to provide precise and reliable data makes them indispensable tools for assessing oil purity, composition, stability, and overall quality.

Choosing the Right Melting Point Meter

Selecting the right melting point meter hinges on several factors:

- Desired level of accuracy and precision: The level of detail required in the analysis will determine the required precision of the meter.

- Sample type and volume requirements: Consider the specific types of oils you will be analyzing and the volume of each sample.

- Additional features: Decide if features like data storage, export capabilities, or specific sample handling methods are necessary for your application.

- Budget and cost considerations: Choose a meter that fits your budget while meeting your essential requirements and offering a good return on investment.

Conclusion

Melting point meters are rapidly becoming a staple in the oil analysis toolbox. Their ability to deliver accurate, efficient, and user-friendly measurements makes them invaluable for ensuring oil quality, optimizing performance, and maintaining consistent standards across diverse industries. As technology continues to evolve, we can expect even more advanced features and functionalities in future melting point meters, further solidifying their place as essential tools in the world of oil analysis.