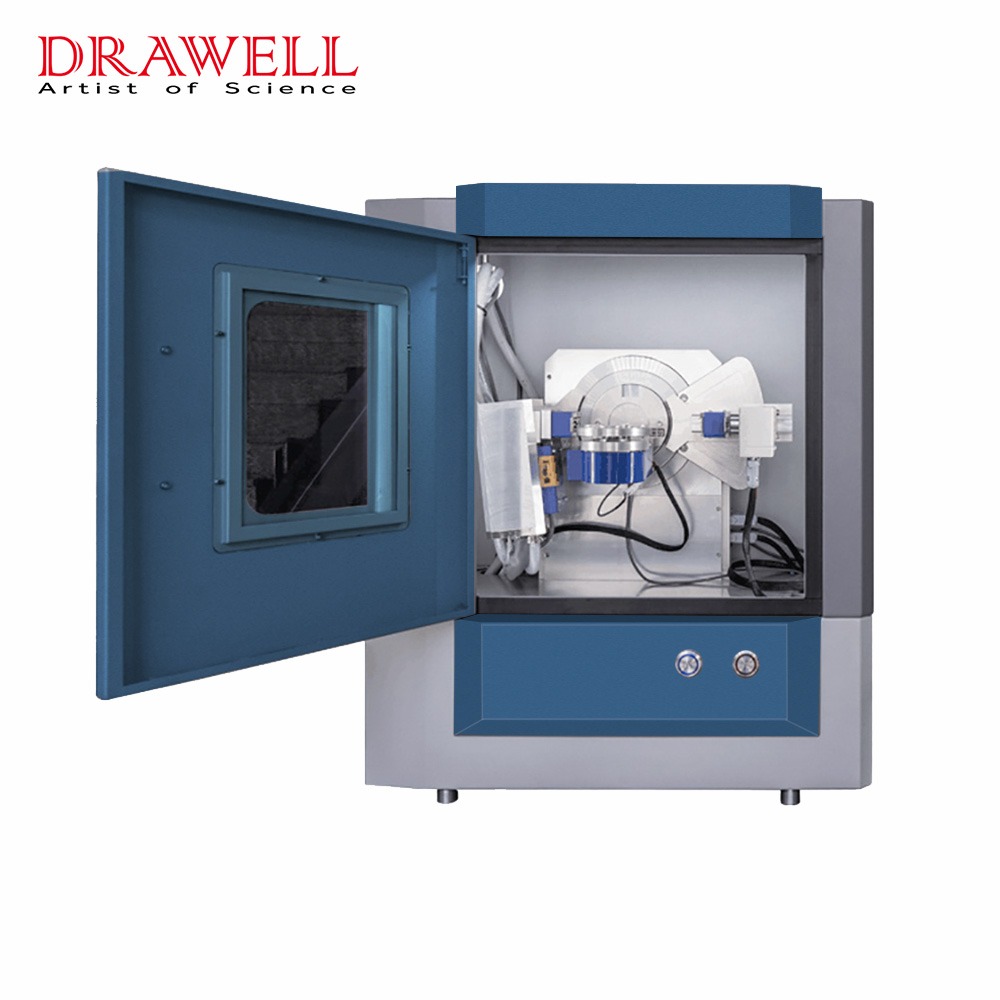

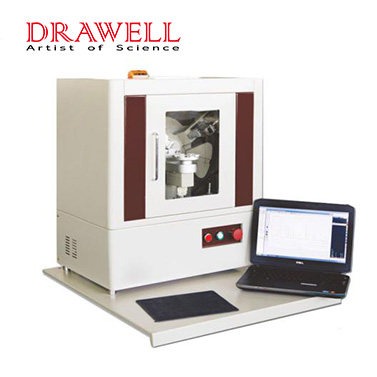

As one of the precision instruments in the laboratory, the X-Ray Diffractometer (XRD) was welcomed by experimenters. Do you need X-Ray Diffractometer (XRD)? Is it an irreplaceable instrument? This article will unravel this mystery for you.

How does an X-ray Diffractometer Work?

The X-ray diffractometer uses the principle of X-ray diffraction to accurately determine the crystal structure, texture, and stress of a substance. X-ray diffractometer can conduct phase analysis, qualitative analysis, and quantitative analysis of substances.

Characteristic X-ray is an electromagnetic wave with a very short wavelength (about 20~0.06nm), which can penetrate a certain thickness of the material and can make fluorescent materials emit light, photographic latex photosensitivity, and gas ionization. The X-ray diffractometer generated by the X instrument bombarding the metal “target” with electron beams includes X-rays with specific wavelengths corresponding to various elements in the target, which are called characteristic (or identifying) X-rays.

Considering that the wavelength of X-rays is similar to the distance between atoms inside crystals, in 1912, German physicist M.von Laue proposed an important scientific theory: crystals can emit diffracted light as X-ray space, that is when A beam X Rays will diffract when they pass through the crystal, and the superposition of diffracted waves will increase the intensity of the rays in some directions while weakening the light in other directions. The structure of the crystal under test can be determined by analyzing the diffraction pattern left on the photographic film. This theory was proved its feasibility in subsequent experiments. In 1913, British physicists WH Bragg and W.L Bragg (WH Bragg, W. .L Bragg), based on Laue’s discovery, not only successfully determined the crystal structure of NaCl, KCl, etc., but also proposed a famous formula as the basis of crystal diffraction─ ─Prague’s Law:

2dsinθ=nλ

In this equation, λ is the wavelength of X-rays, and n is any positive integer. When an X-ray is an incident on a crystal plane with a lattice spacing of d at a grazing angle θ (the complementary angle of the incident angle, also known as the Bragg angle), it will be in the reflection direction under the conditions of the above formula Obtain diffraction lines enhanced by superposition.

What are the Application Areas of X-ray Diffraction?

X-ray diffraction is widely used in metallurgy, petroleum, chemical industry, scientific research, aerospace, teaching, material production, and other fields.

- When the X-ray wavelength λ is known (select characteristic X-rays with a fixed wavelength), you can use fine powder or fine-grained polycrystalline linear samples from a pile of crystals with any orientation from each angle θ to satisfy the Bragg condition The reflecting surface will be reflected. After measuring θ, the Bragg formula can be used to determine the lattice spacing d, unit cell size, and unit cell type;

- X-ray diffraction uses the theoretical basis of the powder method or Debye-Scherrer method in X-ray structure analysis to determine the intensity of the diffraction line to further determine the arrangement of atoms in the unit cell.

- The single-crystal sample used in the Laue method to determine the single crystal orientation needs to keep the measured substance fixed (that is, the θ remains unchanged), and the wavelength λ of the radiation beam is used as a variable to ensure that all the crystal faces meet the conditions of the Bragg formula, so Select a continuous X-ray beam. Then use a crystal with a known structure (called an analytical crystal) for measurement. After obtaining the direction θ of the diffraction line, the wavelength λ of the X-ray can be calculated to determine the element that produces the characteristic X-ray. This is an X-ray spectrometer that can be used to analyze the composition of metals and alloys.

Then use a crystal with a known structure (analysis crystal) for measurement. After the direction θ of the diffraction line is obtained, the X-ray wavelength λ of the crystal can be calculated and analyzed to determine its characteristic X-ray element. This is an X-ray spectrometer that can be used to analyze the composition of metals and alloys.

Application of X-ray Diffractometer in Metallurgy

After the discovery of X-ray diffraction, it was quickly used to study the crystal structure of metals and alloys. It is an effective method to study the microstructure of crystalline materials and certain amorphous materials.

Qualitative analysis and quantitative analysis are the most commonly used methods of X-ray diffraction in the field of mental determination. Qualitative analysis is to compare the measured lattice spacing and diffraction intensity of the material to be tested with the diffraction data of the standard phase to determine the phases present in the material; quantitative analysis is to determine the phases of the material to be tested based on the intensity of the diffraction pattern Proportional content.

The precise determination of lattice parameters is often used to draw the solid-state solubility curve of the phase diagram. The change of solubility often causes the change of the lattice constant; when the solubility reaches the solubility limit, if the solute continues to increase, it will cause the precipitation of new phases, and no longer cause the change of the lattice constant. This turning point is the dissolution limit. In addition, the precise measurement of the lattice constant can obtain the number of atoms per unit cell, which can determine the type of solid solution; it can also calculate useful physical constants such as density and expansion coefficient.

X-rays can be used to determine grain (mosaic) size and microscopic stress. By measuring the shape and intensity of the diffracted light pattern, the size and micro-stress of the crystal grains can be calculated. In the process of metal deformation and heat treatment, both have obvious changes, and these characteristics will directly affect the performance of the material.

In addition, the X-ray diffractometer can also be used to analyze the instantaneous dynamics of metals under high temperature, low temperature, and special conditions.

The above is a basic introduction to X-Ray Diffractometer. Whether you need X-Ray Diffractometer, you need to decide according to your needs. However, X-Ray Diffractometer, as a piece of the indispensable equipment in the laboratory, its functionality and role must be affirmed. In addition, the X-ray diffractometer can also be used to analyze the instantaneous dynamics of metals under high temperature, low temperature, and special conditions. If you need to know more about X-Ray Diffractometer information and purchase requirements, please feel free to contact Drawell International Technology Limited.