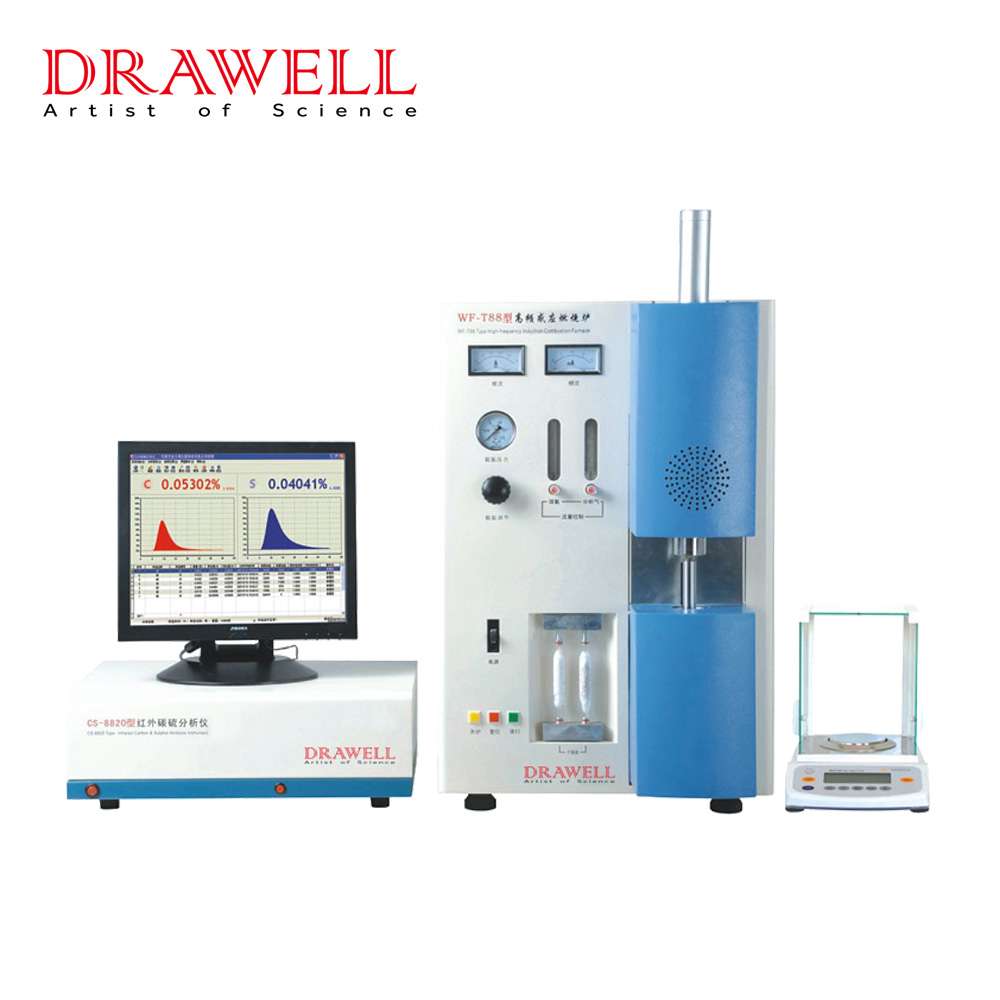

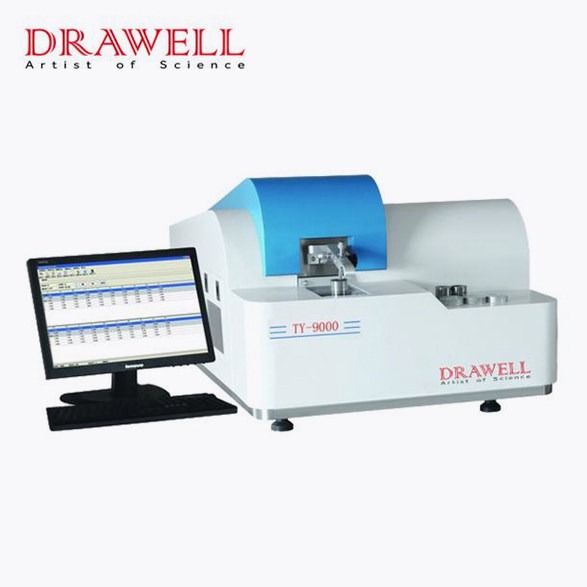

Carbon and Sulfur Analyzer

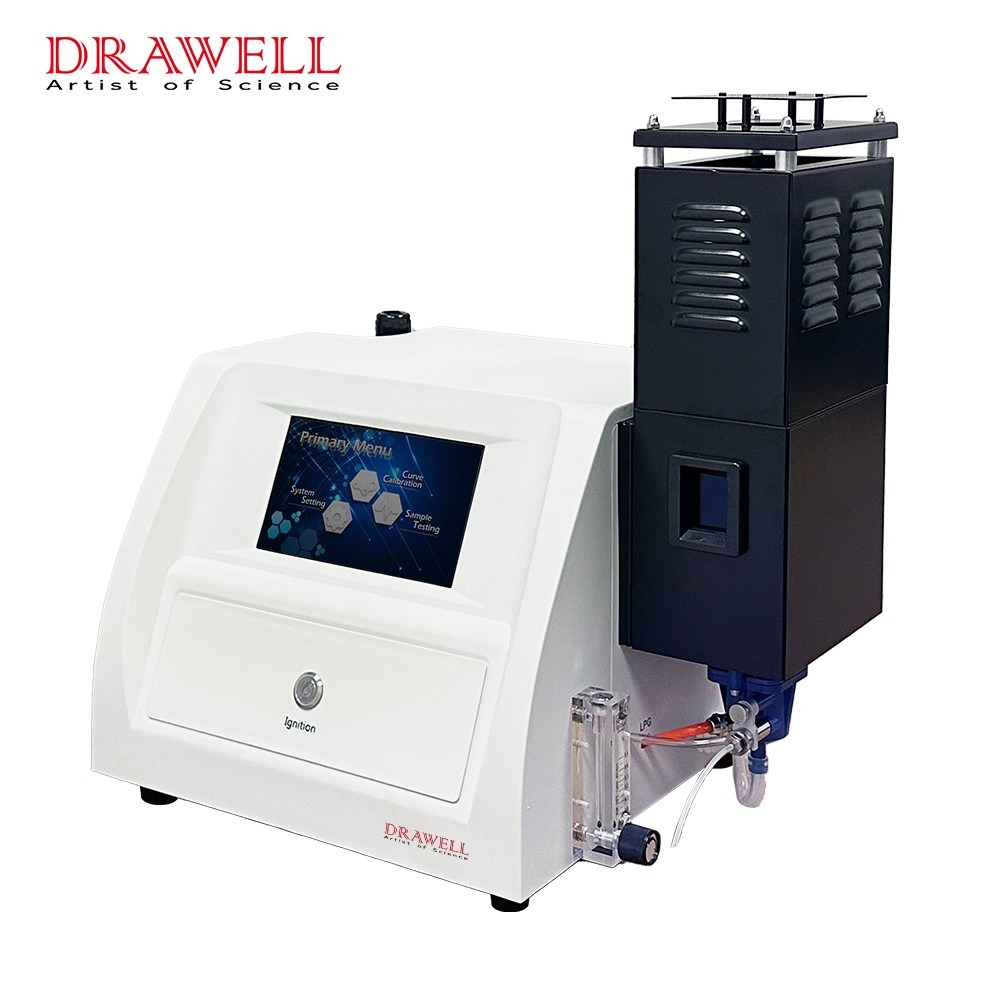

Carbon and Sulfur Analyzer is an instrument that can be used to detect the content of carbon or sulfur in steel, iron, alloys, non-ferrous metals, cement, ores, glass, and other materials. It is a high-tech product integrating light, machine, electricity, computer, and analysis technology, with a wide measurement range, accurate and reliable analysis results, etc.

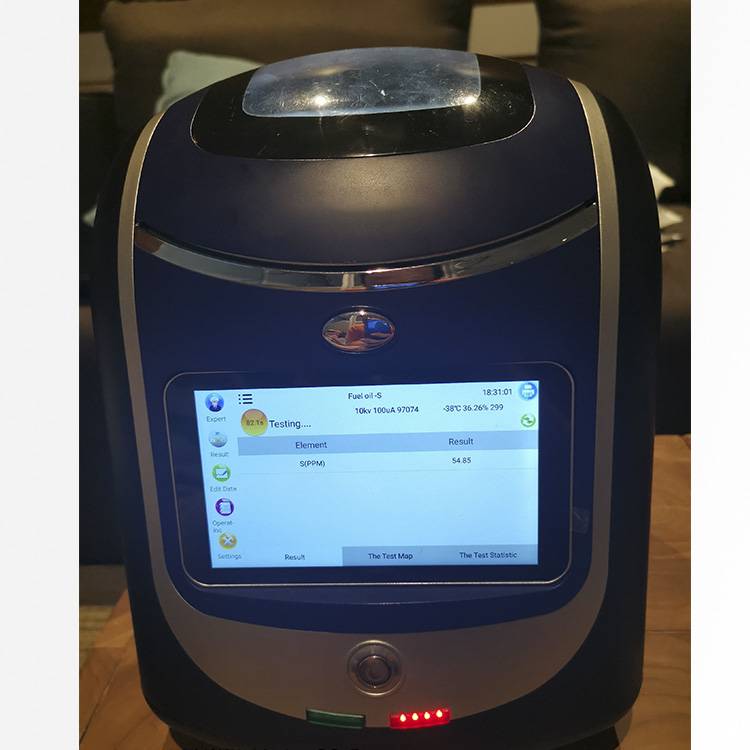

The sulfur element analyzer is a special X-ray fluorescence analyzer used to test the sulfur content in petrochemical products, especially oil products. It adopts the principle of energy dispersion and mechanical and electrical integration microcomputer design. It can quickly and accurately detect the sulfur content in crude oil or petrochemical production processes.

Features of Carbon and Sulfur Analyzer

- Infrared detection system, fast and accurate;

- Beautiful and elegant table structure, easy to operate;

- Independent set of high-frequency infrared analysis software ;

- Powerful data processing and statistical functions;

- Double CPU design, high electronic circuit integration degree, steady and reliable

- High power and quick frequency circuit design to reduce the high-frequency combustion system load and to increase the use time;

- Furnace head automatic cleaning to reduce the effects of dust on test results.

DW-CS-8820T Carbon & Sulfur Analyzer

• S: 0.0001%-95.0000%

• Low C: 1ppm~0.2%, High C: 0.2%~99.99999%

• Low S: 1ppm~0.2%, High S: 0.2%~99.99999%

• Analysis Time: Adjustable within 25-60s

DW-CS-8800S Carbon & Sulfur Analyzer

• S: 0.000001%~99.999999%

• Low C:1ppm~0.2%, High C:0.2%~99.99999%

• Low S:1ppm~0.3%, High S:0.3%~99.99999%

• Analysis Time:30~40S

DW-CS-8820S Carbon & Sulfur Analyzer

• S: 0.0001%-10.0000%

• Sensitivity: 0.1ppm

• Analysis Time: Adjustable within 25-60s

DW-CS-8820 Type High-frequency Infrared Carbon&Sulfur Analyzer

• S: 0.0001%-3.5000%

• Analysis Time: Adjustable within 25-60s

Applications of Carbon and Sulfur Analyzer

Mainly used in unknown samples, cement, ore, coke, catalyst, magnetic materials, ceramics, alloys, aluminum, ashes, carbides, cast iron, inorganic matter, graphite, refractory materials, battery materials, plants, and other materials.

And mainly used in new energy, metallurgy, mechanical, mine, inspection, nuclear industry, coal, automobile, shipping, aviation, food, aerospace, building materials, university, geology, petrochemical and so on.

How to Choose the Carbon and Sulfur Analyzer?

1) What sample do you want to test?

For our model, it’s mainly suitable for testing ferrous metal materials, such as alloy steel, stainless steel, cast iron, etc.

2) What is the Oxygen control method?

It takes sample comparison of standard samples to Ensure the supply of oxygen to the sample during combustion so that the carbon and sulfur content of the sample can be fully converted into CO2 and SO2 gas.

What is the Difference Between Infrared and Thermal Conductivity Detection?

Infrared Detection (NDIR):

- Principle: Measures the absorption of infrared light by CO₂ and SO₂ gases at specific wavelengths.

- Advantages: High sensitivity and specificity for CO₂ and SO₂.

- Usage: Widely used in modern Carbon Sulfur Analyzers for accurate quantification.

Thermal Conductivity Detection (TCD):

- Principle: Measures changes in thermal conductivity of the gas mixture compared to a reference gas.

- Advantages: Universal detector, can detect a wide range of gases.

- Limitations: Lower sensitivity compared to NDIR; less commonly used for C and S analysis.

How Accurate is Carbon and Sulfur Analyzer?

Single/Double Carbon Sulfur Analyzers offer high accuracy and precision:

- Detection Limits: As low as 0.6 ppm for carbon and sulfur.

- Repeatability: Relative Standard Deviation (RSD) typically ≤ 0.5% for carbon and ≤ 1.0% for sulfur.

- Compliance: C: lSO9556; S: lS04935, JJG395-97 standard.

How to Calibrate Carbon and Sulfur Analyzer?

Calibration steps:

- Prepare Standards: Use certified reference materials with known carbon and sulfur content.

- Run Calibration Samples: Analyze the standards to establish a calibration curve.

- Adjust Instrument Settings: Modify detector sensitivity and baseline as needed.

- Validation: Test with quality control samples to confirm accuracy.

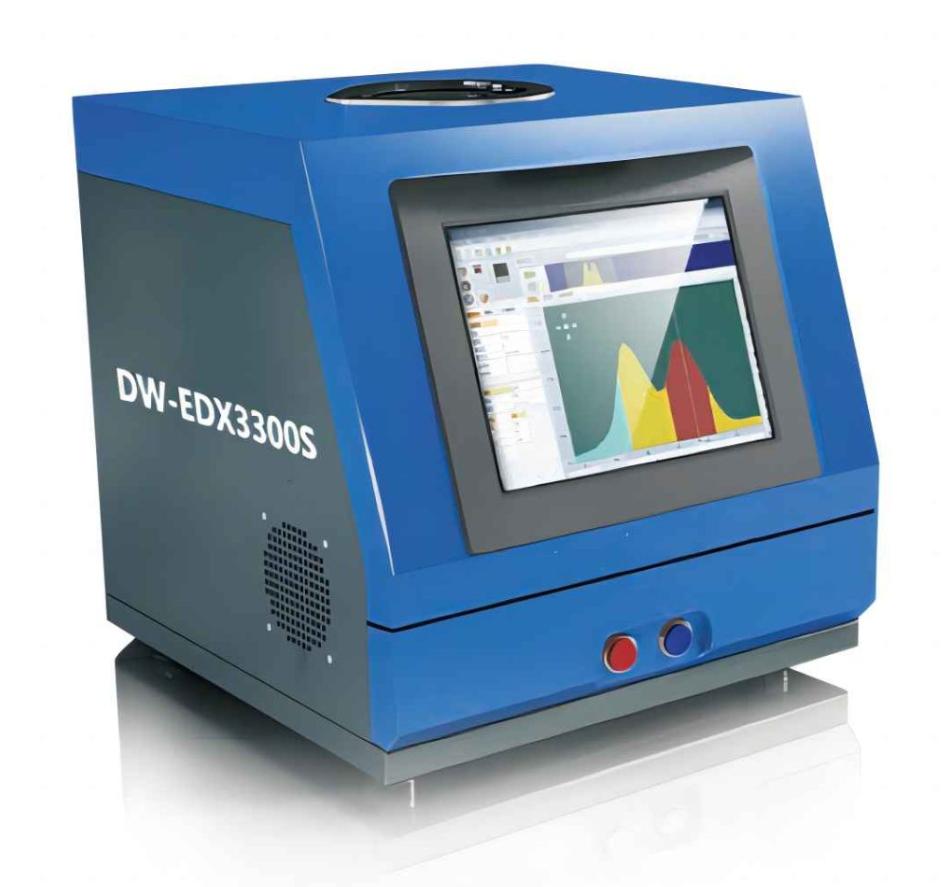

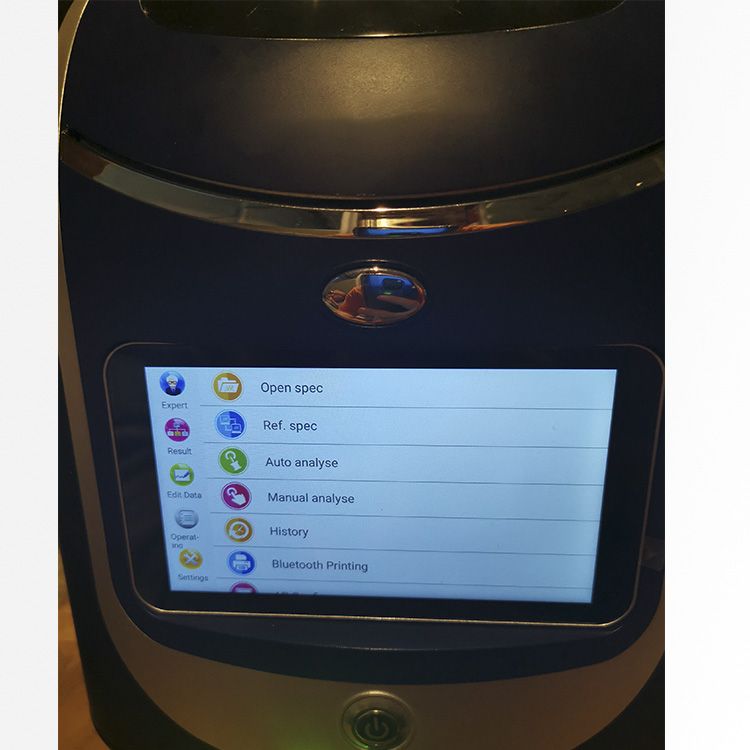

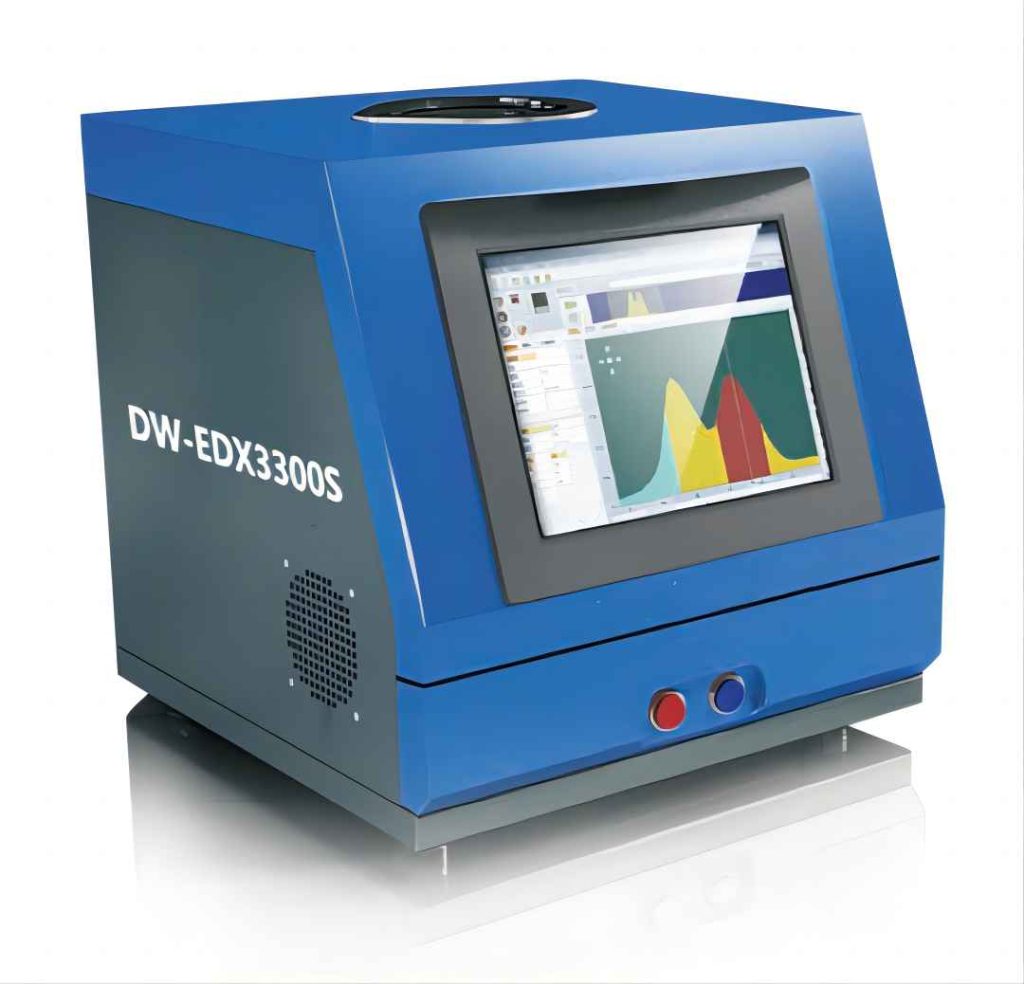

Features of Sulfur Analyzer

- Small and exquisite appearance, simple and integrated design equipped with integrated computer, can be used in both vehicles and laboratories;

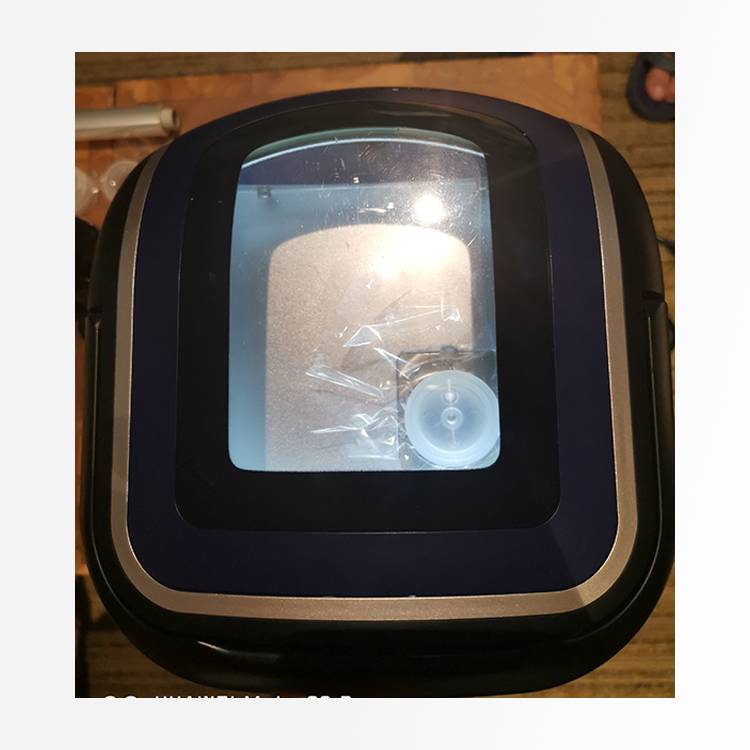

- Vacuum system with no need to fill with helium, reducing test costs;

- Ultra-short test distance, improving the precision of tested samples;

- Down-lighting design, avoiding light tube and beryllium window being contaminated by sample volatilization; capable of measuring light oil such as gasoline and diesel, and improving measurement precision;

- High excitation efficiency side-window, high-power X-ray tube, most advanced SDD detector, and good heat dissipation ensure the high efficiency and stability of the test

- Automatic calibration after power on, ensuring consistent test precision;

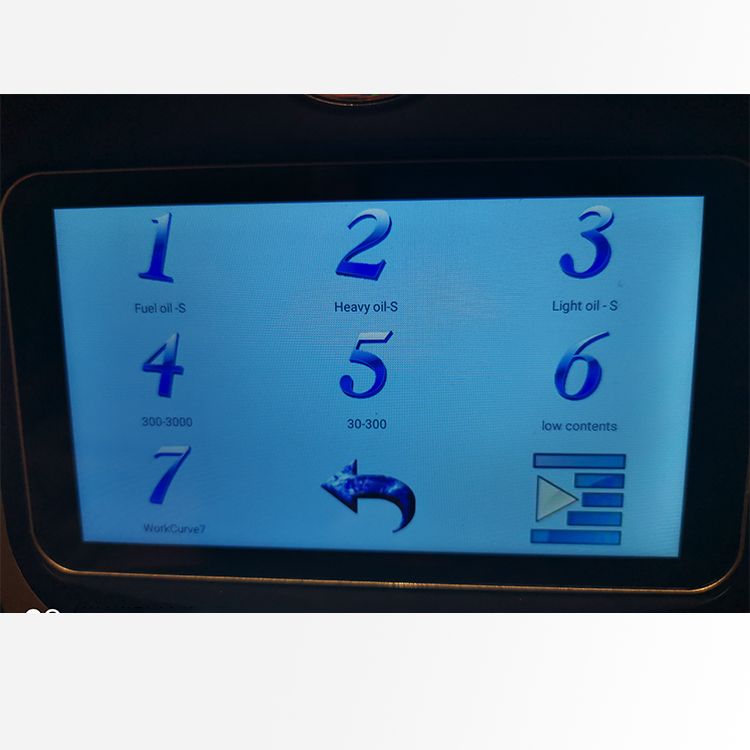

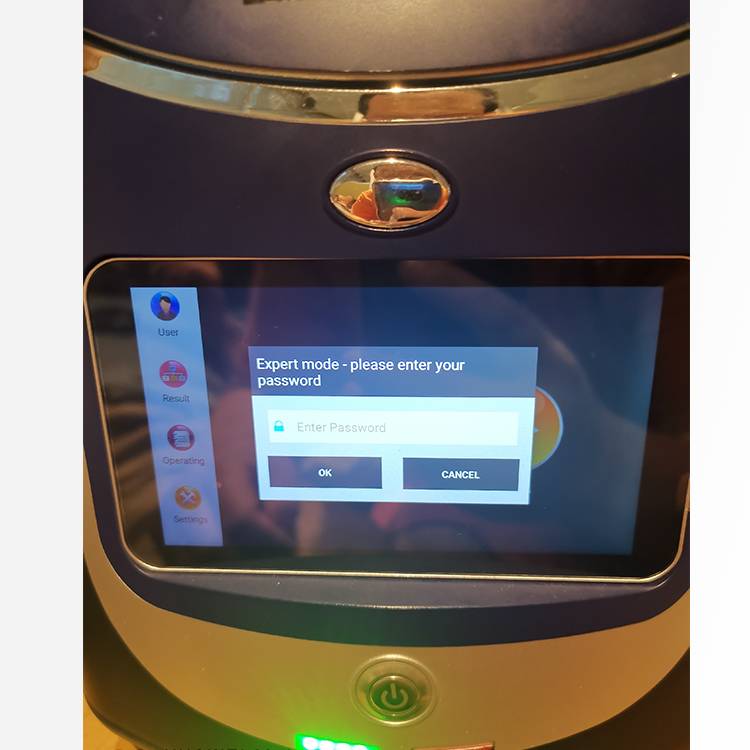

- Intelligent sulfur measuring and analyzing software, one-click operation, intelligent algorithm equipped for detecting low-content sulfur, high-content sulfur, and different oil, no need to manually select curves, reducing test error resulting from manual curve selection;

- X-ray shielded design for safe operation.

Applications of Sulfur Analyzer

The sulfur analyzer is mainly for detecting sulfur in oil products. It is used in various areas including Petrochemical engineering, crude oil exploration, and refining, liquid element analysis, refined oil, and refinery product line monitoring.

How to Choose the Sulfur Analyzer?

1) What’s the approximate content of the sulfur?

We have two models: DW-EDX3300S and DW-Cube-100S. You need to confirm the approximate content of the sulphur. If it’s below 100ppm: you’d better choose DW-EDX3300S; 30-50ppm; if it’s over 100ppm, you can choose DW-Cube-100S.

2) Do you also need to test chlorine?

If you also need to test chlorine elements, you must choose DW-EDX3300S.

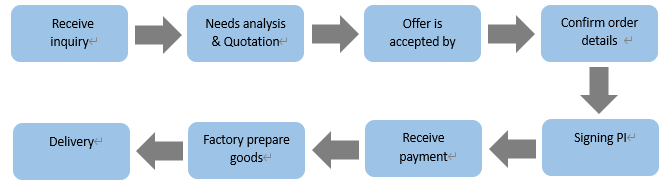

Order Process of Infrared Carbon and Sulfur Analyzer

Why Choose Us for Infrared Carbon and Sulfur Analyzer?

“Multiple suppliers” have always been an issue in the procurement process. Drawell as a one-stop laboratory equipment and scientific instruments supplier, can perfectly solve this problem. In addition to manufacturing our own equipment, we also represent other laboratory equipment. Our product lines are rich and diverse at competitive prices. Provide one-stop service to customers.

User Training – Training by Drawell skilled engineers about installation, debug tests, technical services, etc. It can happen in our factory in China, or at the site in the customers’ country. Cost depends on where and when the training happens.

To discuss the problem and get it resolved, online chats, real-time video calls, and remote guidance. For the after-sales stage, our online technical guidance is free and ready forever.

1 year free official warranty, including repairing quality-damaged parts, and offering replacements of selected parts (shipping cost is extra). 5% of the product price is charged for extending the warranty before the end of the official warranty.