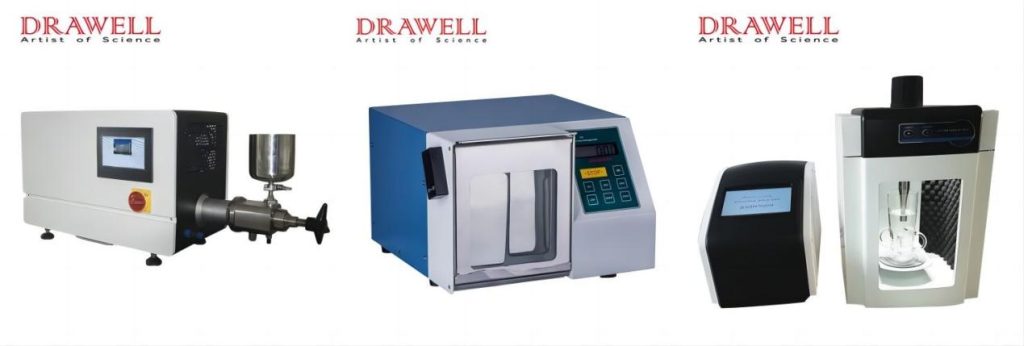

Homogenizers are essential laboratory equipment used to mix and break down various substances. Homogenizers can be used for a wide range of applications, including cell disruption, nanoparticle synthesis, emulsion formation, and microbial culture. Three commonly used homogenizers are Ultrasonic Homogenizers, High-Pressure Homogenizers, and Sterile Slap Homogenizers. While they all serve the same purpose, they differ in their operating principles, sample preparation requirements, sample sizes, applications, and sterility.

1. Operating Principle Difference Among Ultrasonic, High-Pressure, and Sterile Slap Homogenizers

Ultrasonic Homogenizers use high-frequency sound waves to create cavitation bubbles in the sample. The bubbles then collapse, generating intense shear forces that break down and mix the sample. Ultrasonic Homogenizers are suitable for processing small sample sizes and are used in applications such as nanoparticle synthesis and cell disruption.

High-Pressure Homogenizers use mechanical force to homogenize the sample. The sample is forced through a narrow orifice or valve at high pressure, typically between 10,000-30,000 psi. The mechanical force generates intense shear forces that break down and mix the sample. High-Pressure Homogenizers are ideal for processing larger sample sizes and are commonly used for particle size reduction, cell disruption, and emulsion formation.

Sterile Slap Homogenizers use mechanical force with beads or balls. The sample is placed in a tube with small beads or balls, and the tube is agitated or “slapped” at high speed. The mechanical force generated by the beads or balls disrupts and mixes the sample. Sterile Slap Homogenizers are commonly used for DNA extraction, protein extraction, and microbial culture.

2. Sample Preparation Difference Among Ultrasonic, High-Pressure, and Sterile Slap Homogenizers

Ultrasonic Homogenizers require minimal sample preparation. The sample is simply placed in a container with a small amount of liquid. The sample can be in solid or liquid form, and it doesn’t need to be pre-disrupted or ground to small particle size.

High-Pressure Homogenizers and Sterile Slap Homogenizers, on the other hand, require more extensive sample preparation. The sample must be pre-disrupted or ground to a small particle size before being homogenized. This is because these homogenizers apply more mechanical force to the sample and can cause damage to the equipment if the sample is not properly prepared. High-Pressure Homogenizers require the sample to be in liquid form, while Sterile Slap Homogenizers can also work with solid samples.

3. Sample Size Difference Among Ultrasonic, High-Pressure, and Sterile Slap Homogenizers

Ultrasonic Homogenizers are effective at processing small sample sizes, typically less than 1 mL. They are commonly used for applications such as nanoparticle synthesis, cell disruption, and emulsion formation.

High-Pressure Homogenizers are better suited for larger sample sizes, typically ranging from 1 mL to 20 L. They are commonly used for particle size reduction, cell disruption, and emulsion formation. High-Pressure Homogenizers can also be used for food processing applications, such as dairy and meat homogenization.

Sterile Slap Homogenizers are suitable for processing larger sample sizes, typically ranging from 0.5 mL to 50 mL. They are commonly used for DNA extraction, protein extraction, microbial culture, and sample preparation for PCR.

4. Application Difference Among Ultrasonic, High-Pressure, and Sterile Slap Homogenizers

Ultrasonic Homogenizers are suitable for applications such as cell disruption, nanoparticle synthesis, and emulsion formation. Ultrasonic Homogenizers are widely used in the pharmaceutical and biotech industries for drug delivery and formulation development.

High-Pressure Homogenizers are ideal for applications such as cell disruption, particle size reduction, and emulsion formation. High-Pressure Homogenizers are commonly used in the food industry for dairy and meat homogenization, as well as in the chemical industry for particle size reduction and dispersion.

Sterile Slap Homogenizers are commonly used for DNA extraction, protein extraction, and microbial culture. Sterile Slap Homogenizers are widely used in the microbiology industry for sterile sample preparation.

5. Sterility Difference Among Ultrasonic, High-Pressure, and Sterile Slap Homogenizers

Sterile Slap Homogenizers can be used for sterile sample preparation, which is critical for certain applications such as microbiology. Sterile Slap Homogenizers are designed to prevent contamination and can be sterilized before use.

Ultrasonic Homogenizers and High-Pressure Homogenizers are typically not used for sterile sample preparation. However, they can be used with pre-sterilized samples or in a sterile environment.

In conclusion, the choice of homogenizer depends on the specific requirements of the sample and the intended application. Ultrasonic Homogenizers, High-Pressure Homogenizers, and Sterile Slap Homogenizers all have unique advantages and are suitable for different applications. Understanding the operating principles, sample preparation requirements, sample sizes, applications, and sterility of each type of homogenizer is essential in selecting the appropriate homogenizer for a specific application.