XRD test is one of the commonly used tests, but there are still many students who don’t know much about it. In this article, Drawell will introduce the problem of the XRD test to you.

1. What is the use of XRD, can you see its purity? Or can you see that it contains some kind of functional group?

When X-rays hit the material, scattering occurs. The coherent scattering of X-rays by crystalline substances is a diffraction phenomenon, that is, the incident beam does not diverge but its direction is changed and its wavelength remains unchanged when the incident beam exits. This is a phenomenon unique to crystalline substances.

The vast majority of solid-state substances are crystalline or microcrystalline or quasi-crystalline and can produce X-ray diffraction. The crystal microstructure is characterized by a periodic long-range ordered structure. The X-ray diffraction pattern of a crystal is a physical transformation of the three-dimensional scene of the crystal microstructure, which contains all the information about the crystal structure. Its X-ray diffraction pattern can be obtained with a small amount of solid powder or a small sample.

XRD (X-ray diffraction) is currently the most powerful method to study the crystal structure (such as the type and position distribution of atoms or ions and their groups, the shape, and size of the unit cell, etc.).

XRD is especially suitable for phase analysis of crystalline substances. If the constituent elements or groups of crystalline substances are different or their structures are different, their diffraction patterns show differences in the number of diffraction peaks, angular positions, relative intensity order, and even the shape of diffraction peaks.

Therefore, the qualitative identification of the phase composition and structure of the sample can be completed through the comparative analysis of the X-ray diffraction pattern of the sample and the X-ray diffraction pattern of the known crystalline substances; the analysis and calculation of the diffraction intensity data of the sample can be completed. Quantitative analysis of the phase composition of samples.

2. How to determine from the XRD pattern that the sample is quasi-crystalline? How to strictly distinguish amorphous, quasi-crystalline, and crystalline structures in XRD patterns?

There is no strict and clear demarcation between the three. On a diffractometer-obtained XRD pattern, if the sample is a better “crystalline” material, the pattern is characterized by several or more narrow “spikes” (2Θ widths at half-height) that are generally independent of each other. 0.1°~0.2°, this width can be regarded as the “minimum width” of the crystal diffraction peak determined by the experimental conditions).

If these “peaks” are significantly broadened, it can be judged that the crystals in the sample will have a particle size of less than 300 nm and can be called “microcrystals”. There is a Scherrer formula in the X-ray diffraction theory of crystals: the thickness of the crystal grains in the diffraction direction can be estimated from the amount of spectral line broadening.

The characteristic of the amorphous diffraction pattern is that only a gentle change in the intensity of scattered X-rays is observed over the entire scanning angle range (from 2θ 1°~2° to several tens of degrees), during which there may be one to several maximum values; at the beginning because the intensity of the direct beam is relatively large, the intensity decreases rapidly with the increase of the angle, and the intensity gradually tends to the background value of the instrument at a high angle.

From the point of view of the Scherrer formula, this phenomenon can be regarded as the result that the diffraction peaks of the crystal being greatly broadened, overlapped, and blurred due to the extremely fine grain size. The limit of grain refinement is that only the “short-range order” between particles such as atoms or ions is left, which is the scene of the “amorphous” microstructure we envision. A maximum on an amorphous diffraction pattern corresponds to a frequently occurring interparticle distance in the amorphous.

The transition between these two types and some “amorphous” is the “quasicrystalline” state.

3. When doing X-ray diffraction, if a different target is used, such as a copper target or a Cr target, will the spectra of the two be the same?

Different targets have different characteristic wavelengths. The diffraction angle (also commonly referred to as the Bragg angle or the 2θ angle) is determined by the wavelength used in the experiment (Bragg equation).

The use of different targets means that the wavelengths of X-rays used are different. According to the Bragg equation, the diffraction angle of a crystal face family with a certain spacing d will be different, and the diffraction angle of the crystal face family with each spacing value will show regular changes. . Therefore, the positions of the diffraction peaks on the diffractograms obtained by X-ray tubes using different targets are not the same, and the changes of the positions of the diffraction peaks are regular.

And a crystal’s own set of d values is inherent in its structure and can be used as a marker parameter for the crystal substance. Therefore, regardless of the target X-ray tube used, a set of d values for a sample obtained from the obtained diffractogram is independent of the target material.

The relative intensities between the diffraction peaks on the diffraction pattern are mainly determined by the crystal structure, but the absorption properties of the sample are also related to the wavelength of the incident rays. Therefore, the relative intensities of the diffraction peaks on the spectra obtained by different targets for the same sample will be slightly different, which is related to the target material.

4. I want to know the crystal planes corresponding to different diffraction angles, what should I do?

If your graph can find the corresponding powder diffraction data card, then the problem is simple. Most powder diffraction data cards give the diffraction index of each diffraction line so that the corresponding crystal plane can be known.

If it is a picture of an unknown crystal structure, it is necessary to solve the diffraction index of each diffraction line. This step is called “indexing the diffraction pattern”. If you solve it yourself, you need to have basic knowledge of crystallography, and then learn one or two indexed tool software (such as treaor90) to try.

5. How to know the atomic coordinates in the crystal?

Do single-crystal X-ray diffraction to get the coordinates of the atoms. In addition to four circles, the CCD can also perform single-crystal X-ray diffraction.

6. How to calculate grain size lattice constant and distortion from X-ray diffraction data, what theory and formula are used?

The grain size lattice constant and distortion can be calculated from the peak shape data of the diffraction peaks. In the case that the broadening of the diffraction peak is only caused by the fineness of the crystal grains, the thickness of the crystal grains in the diffraction direction can be estimated by the Scherrer formula according to the broadening of the diffraction peak.

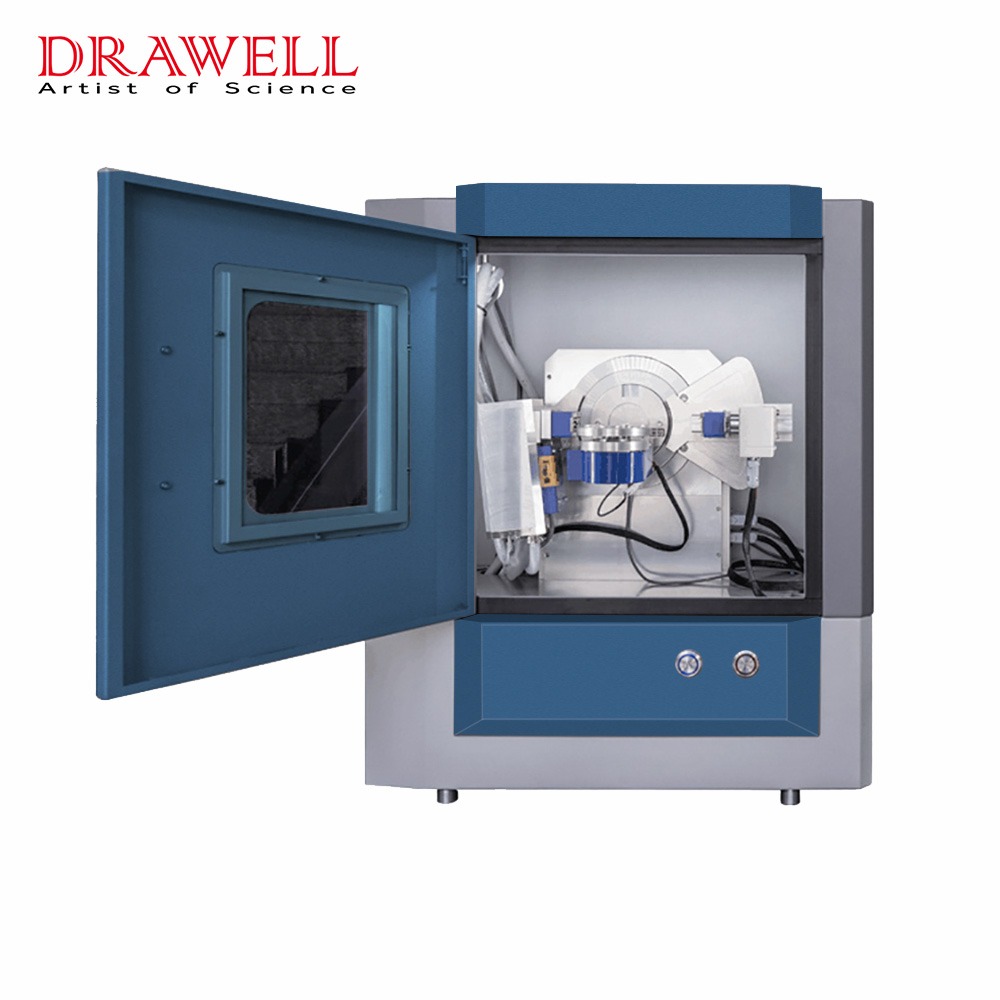

The above is the arrangement of the common problems of XRD. If you need an XRD test or the XRD instrument, you can contact Drawell XRD manufacturer.