Sterilization is the most fundamental method to ensure the safety and effectiveness of a lab environment. By making sure that all surfaces including equipment and equipment are free of contaminants, sterilization can reduce the chance of errors in experiments as well as cross-contamination and spreading of infectious agents. We will explore a variety of sterilization techniques as well as equipment that are commonly employed in laboratories, and offer an extensive guide for selecting the best option for your the specific requirements.

Purpose of Sterilization in Laboratories

The main goal of laboratory sterilization is to kill or eliminate the microbial life in all its forms which includes viruses, bacteria and spores, as well as fungi. This is crucial for many reasons:

Safety Protection of lab workers from exposure to pathogens that cause harm.

Accuracy Assuring that experiment results are not affected by contaminants from outside.

Compliance Conforming to regulations and standards of institutions for biosafety and cleanliness.

In clinical, research, as well as industrial labs Effective sterilization procedures are crucial to ensure the highest quality of results as well as maintaining a healthy working conditions. Failure to properly sterilize could lead to the failure of experiments as well as wasted resources and serious health risks.

Common Sterilization Methods

Laboratories use a variety of sterilization methods that are classified into chemical, physical mechanical, and physical approaches. Each method targets microorganisms with various mechanisms. The decision to use the method will depend on the type of substance being sterilized, the varieties of microorganisms in the material and other practical factors like time and cost.

Physical Methods

Physical methods of sterilization depend on physical substances like heating, filtration and radiation to kill microorganisms. These techniques are commonly utilized due to their effectiveness and usually leave no chemical residuals.

Heat Sterilization

Heating sterilization is one of the most trusted and oldest methods to eliminate microorganisms. Temperatures that are high denature important microbial proteins as well as nucleic acids, resulting in the death of cells. Two major kinds of heat sterilization typically used:

Dry Sterilization of Heat: This process generally involves using a high air oven with temperatures that range from 160degC up to 180degC over prolonged time periods (e.g. 1 to 2 hours). Dry heat is efficient for the sterilization of glassware and metal instruments, as well as thermally stable powders that could be damaged by moisture. The extended exposure time and the high temperatures are required since dry heat penetrates the material less effectively than humid heat. For example sterilizing glassware in an oven with a dry temperature of 170°C for an hour will ensure that the total inactivation of extremely resistant bacterial spores.

Moist heat sterilization (Autoclaving): Autoclaving makes use of steam under pressure to attain an effective sterilization. The combination of high temperatures (typically 121°C or 134°C) along with the pressure (usually 15-20 psi over atmospheric pressure) permits greater efficiency in heat transfer and the denaturation of microbial components within less period of time (e.g. fifteen to thirty minutes). Moist heat is efficient against a broader range of microorganisms including spores. It is widely used to sterilize media for culture as well as surgical instruments, liquids as well as some heat-stable plastics. The effectiveness of autoclaving is typically determined by using biological indicators like Geobacillus stearothermophilus, spores which are extremely resistant to heat that is moist. A successful autoclave process can result in deactivation of these spores, which will confirm the proper sterilization.

It is important to note that heat sterilization, wet or dry, has been an essential component of sterilization protocols in laboratories because of its effectiveness and low cost for a variety of applications. The decision between these two options is based on the type of objects being sterilized as well as their sensitivity to heat.

Filtration

Filtration is a technique used to physically eliminate microorganisms from gases and liquids. This method involves running substances through filters having pores small enough to catch bacteria, fungi as well as certain viruses. Membrane filters that have defined pore dimensions, which typically range between 0.1 to 0.22 millimeters, are used to sterilize heat-sensitive substances such as protein solutions antibiotics, and other tissue culture media which could be destroyed by the heat.

The process of filtration does not eliminate microorganisms but instead removes the microorganisms, which results in an sterile filter. The effectiveness of filtration is contingent on the size of the pores in this filter, as well as on the viscosity the liquid, and also the pressure that is applied. For instance, sterile filtration is essential in the production of pharmaceuticals to ensure that injectable medications are safe from contamination by microbes without exposing them to high temperatures. Although filtration can be a successful method of sterilization for specific applications but it’s not suited to sterilize solid materials or viscous fluids that are unable to easily traverse the filter.

Radiation

The use of electromagnetic energy to destroy the DNA of microbial organisms and other vital cells, resulting in the inactivation of cellular components. Two kinds of radiation are utilized in labs for sterilization:

Ultraviolet (UV) Radiation Light from UV specifically at wavelengths between 220 nm, has germicidal properties. It is typically used to sterilize surfaces of laminar flowhoods, biosafety cabinets, as well as the surfaces of laboratories. UV radiation is efficient against viruses and bacteria but it is not as effective at penetrating and is not as efficient against the spores. The effectiveness of UV radiation is also diminished due to the presence of organic matter or dust that could shield microorganisms. For example UV lamps are commonly used to create a sterile working conditions within the biosafety cupboards in between uses.

Ionizing radiation (Gamma as well as Electron beam): Ionizing radiation such as gamma radiation or electron beams possess more energy and permeating force in comparison to UV radiation. It is able to effectively sterilize the most heat-sensitive materials like pharmaceuticals, plastics, and medical equipment. This method is typically used to sterilize disposable laboratory equipment like pipettes, petri dishes and syringes, by industrial sterilization units. The process involves exposing items to a predetermined amount of radiation that destroys the microbial DNA and renders them unusable. Although highly effective, using Ionizing radiation is a process that requires special equipment and safety measures because of the risk that are associated with high-energy radiation.

Radiation sterilization is a great method of making materials more resistant to chemical or thermal treatments. The decision of UV and ionizing radiations is based on the specific needs of the application as well as the level of penetration required and efficiency.

Chemical Methods

Chemical sterilization is the process of using of chemical agents, also known as sterilants, in order to eradicate microorganisms. The chemicals disrupt the essential processes of cells, and damaging cell membranes or reducing the nucleic acid and proteins. Chemical sterilization is commonly used to sterilize heat-sensitive surfaces and instruments that aren’t sterilized using physical methods. The most common chemical sterilizers are:

Ethylene Oxide (EtO): EtO is a gaseous sterilant which is extremely efficient against a variety of microorganisms, such as spores. It is used extensively to sterilize medical devices sensitive to heat surgical instruments, surgical instruments, as well as certain lab equipment. Sterilization using EtO requires specially designed chambers that control the concentration of gas and temperature, humidity, and time for exposure. Following sterilization, an extended time of aeration is required to eliminate the toxic EtO residues. Although effective, EtO is flammable and possibly carcinogenic, and requires care in handling and monitoring.

Liquid Chemical Sterilants A variety of liquid chemicals, including formaldehyde (formaldehyde), glutaraldehyde acid as well as hydrogen peroxide (at very high levels) are able to achieve sterilization when used for prolonged contact time. These sterilants are typically used to sterilize medical and dental instruments that are heat-sensitive which are not autoclavable. The efficacy of liquid chemical sterilizants is contingent on variables like concentration and timing of the contact and temperature in addition to the existence of organic matter. For instance an 2% glutaraldehyde solution is able to be sterilized after a few hours of exposure. It is essential to thoroughly wash items that have been cleaned with liquid chemicals to eliminate any toxic residues prior to using.

Chemical sterilization can be a beneficial alternative for the materials that are unable to be sterilized with radiation or heat. It is important to choose the correct chemical sterilizant, abide by suggested concentrations and contact time and ensure adequate ventilation and safety measures due to the potential toxic nature of these chemicals.

Mechanical Methods

Although the phrase “mechanical sterilization” is less frequent, it usually refers methods that mechanically eliminate microorganisms instead of killing or inhibiting them. Filtration, as discussed previously is one of the methods that is mechanical. Other methods of mechanical engineering include:

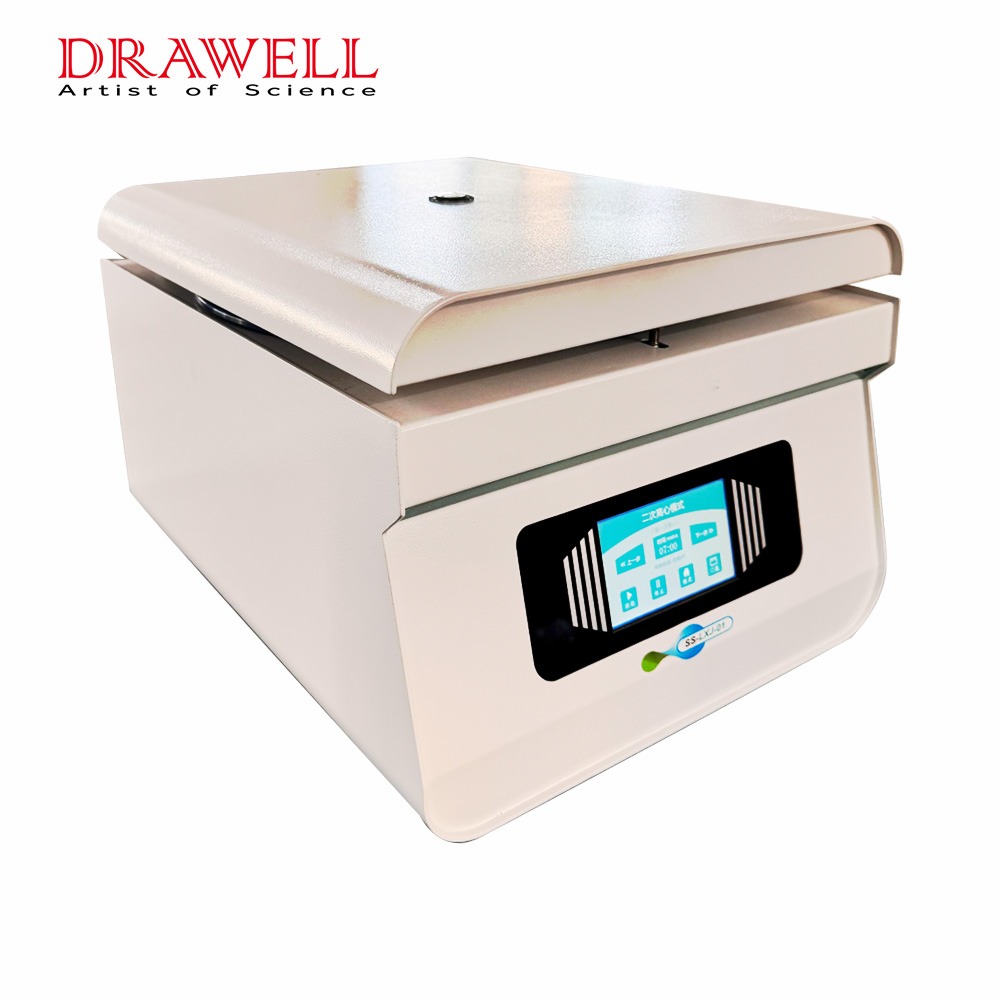

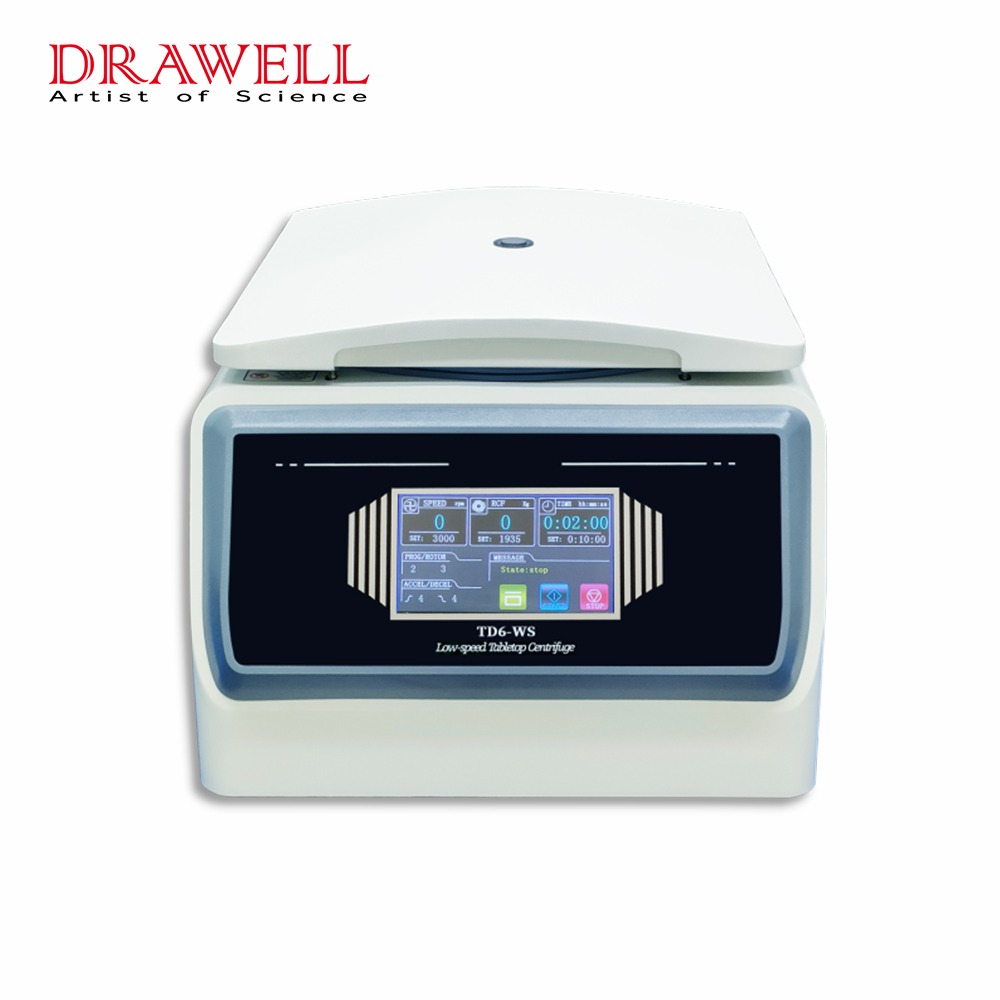

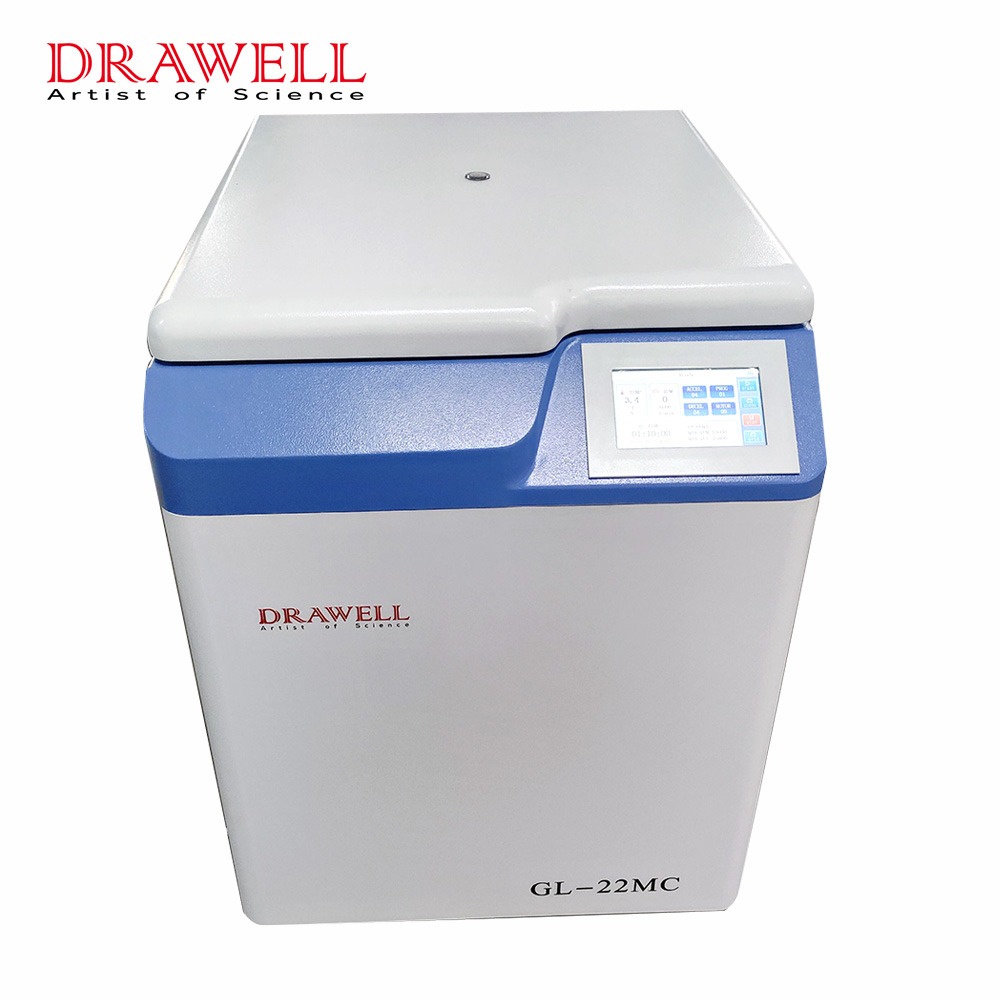

centrifugation: High-speed centrifugation can be utilized to distinguish microorganisms from liquids by their dimensions and densities. Although it’s not a real sterilization technique since it doesn’t have to kill microorganisms in all cases it can greatly reduce the amount of microbial matter in an experiment. For instance, centrifugation is employed in a variety of methods of water purification to remove larger microorganisms and particles.

Ultrasonication Ultrasonication: High-frequency sound waves may disrupt microbes, causing their destruction. Ultrasonication can be typically employed to clean and disinfect instruments however it is not able to provide complete sterilization by itself, particularly against spores that are resistant.

Applications-of-Ultrasonic-Cleaner

The mechanical techniques focus primarily on the physical elimination or disintegration of microorganisms. They are typically utilized together with other disinfection or sterilization techniques to reach the desired level of microbiological control. Although they are not usually classified as the primary sterilization method but they are a crucial element in reducing the risk of contamination by microbial organisms in different lab applications.

Common Equipments for Lab Sterilization

The efficient execution of sterilization techniques relies on specially designed equipment to provide the sterilization agent of choice within controlled circumstances. Here are some of the equipments commonly used:

| Equipment Category | Equipment Name | Key Features | Suitable Tools & Materials | Notes |

| Heat Sterilization | Dry Heat Oven | Temperatures that are high (160-180degC) controlled heating, timer, usually using forced air circulation to ensure uniform heat distribution. | Glassware (e.g. flasks, beakers, pipettes) Metal instruments oil, heat-stable powders. | It requires longer time to sterilize in comparison to humid heat. Not recommended for materials that are sensitive to heat or liquids. |

| Autoclave (Steam Sterilizer) | High-pressure steam (typically between 121 and 134 degrees Celsius at 15 to 20 psi) controlled cycles, temperature and pressure gauges and safety valves. | Culture media Glassware, liquids Certain heat-stable plastics surgical instruments biological waste. | Highly effective against a broad spectrum of microorganisms including spores. It requires steam penetration, therefore it is vital to load the right way. Effectiveness is often measured using biological indicators. | |

| Filtration | Filter Systems (Membrane) | Membrane filters with defined pores dimensions (0.1-0.22 um) in different sizes and types of materials (e.g. such as PVDF, cellulose acetate) and syringes, or vacuum-driven. | Liquids that are heat-sensitive (e.g. proteins solution, antibiotics and some tissues media for culture). | Physically removes microorganisms but is not a way to cause death. The choice of size of the pores is vital. Not suitable for sterilizing gases or viscous fluids. |

| HEPA Filter Units | The High-Efficency Particulate Air (HEPA) filters which remove airborne particles greater than= 0.3 um, with 99.97 percent effectiveness. Integrated into workplaces. | Air in laminar flow hoods and biosafety cabinets, resulting in the perfect work environment. | Mainly for maintaining the quality of air and to prevent contamination of processes and samples. This method does not sterilize equipment, or the materials within them the container unless used in conjunction by other techniques (e.g. the UV light). | |

| Radiation | UV Lamps & Cabinets | emit ultraviolet light that is germicidal (around the wavelength of 260 nanometers) which is often included in biosafety cabinets, or in sterilization cabinets. | Surfaces of work areas as well as equipment inside the cabinet. Limited penetration. | Effective in surface decontamination of both viruses and bacteria. It is less effective against spores and shielded microorganisms. Requires direct exposure. Security precautions are required to prevent contact with eyes and skin. |

| Gamma Irradiators | Make use of high-energy gamma radiations emanating from radioactive elements (e.g. Cobalt-60, for instance). The penetrating power is high. | Sterilization of bulk-sized heat-sensitive materials and medical supplies that are disposable lab consumables (e.g. petri dishes pipettes, syringes). | Typically, commercial facilities perform this because of safety and the requirements of regulatory agencies. This provides high levels of sterility. It can cause material degrading. | |

| Electron Beam Accelerators | Generate high-energy electron beams. Excellent penetration, but less than the gamma radiation. | The same applications are used for gamma radiation is often used in medical equipment and packaging. | Most often, commercial facilities. It has a faster processing time as compared to gamma radiation. Penetration depth is material-dependent. | |

| Chemical Sterilization | Ethylene Oxide (EtO) Sterilizers | Controlled environment, with specific temperatures, humidity, EtO gas concentration, and exposure duration. It also includes aeration cycle. | The medical devices are sensitive to heat and moisture surgical instruments, a few electronic equipment. | Very effective in combating a wide variety of microorganisms including spores. It requires careful monitoring and long air aeration in order to eliminate the toxic residues. It is carcinogenic and flammable. needs strict safety guidelines. |

| Soaking Trays/Containers (for Liquid Sterilants) | Non-reactive containers to immerse instruments in chemical sterilants that are liquid (e.g. glutaraldehyde, peracetic acid). | Instruments for dental and medical use that are sensitive to heat which cannot be autoclaved. | The duration of sterilization is determined by the chemical in question and the concentration. The instruments must be thoroughly rinsed after sterilization to eliminate harmful residues. A good ventilation system and personal protective equipment are vital. |

Disinfection-And-Sterilization-Equipment

Tips for Choosing the Right Method and Equipment

The selection of the most suitable sterilization technique along with the appropriate apparatus to use in a particular laboratory use involves careful consideration of a variety of aspects:

The Nature of the Material The substance being sterilized is the main element. Materials that are sensitive to heat require techniques like chemical sterilization or filtration, while those that can withstand heat can be efficiently sterilized using the autoclave and dry heating.

The type of microorganism The microorganisms have various levels of resistance sterilization techniques. For instance the spores of bacterial species are resistant to heat as well as chemical sterilizants, which requires stricter conditions.

required Sterility Assurance Level (SAL): The SAL is the likelihood of a non-sterile item following sterilization. In the case of critical applications, like the surgical instrument, a large SAL (e.g. 10-6, which is 1 in a million chance of an item that is not sterile) is necessary.

Cost and throughput Cost and Throughput: The price of equipment, consumables and the time needed to sterilize can differ significantly between different methods. The quantity of the materials that need being sterilized (throughput) can also affect the selection of the equipment.

Safety Beware of Certain sterilization techniques including chemical sterilization using EtO as well as high-dose radiation could pose a risk to workers as well as the environment, and require specific safety procedures and equipment.

Compatibility Check that the method chosen and the equipment used are compatible with the material that will be sterilized in order to prevent the possibility of damage or degrading.

When carefully analyzing these aspects, laboratories can choose the sterilization techniques and equipment that will best suit the requirements of their particular lab in order to ensure efficient control of microbial growth and ensuring the quality in their activities.

The variety of chemical, physical and mechanical techniques each with their particular principles and application offer laboratories an extensive toolkit to eliminate microbes that cause contamination. Selecting the right sterilization equipment and methods, supported by a thorough knowledge of the substances microorganisms, the level of sterility, as well as security considerations. As research and development continues to develop the significance of efficient and safe sterilization methods will only grow, ensuring the accuracy and safety of laboratory work in all disciplines.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.