In laboratory environments where contamination control is critical, laminar flow cabinets are vital in protecting samples, equipment, and personnel. Depending on the direction of airflow, laminar flow cabinets are categorized into two main types: vertical and horizontal. Each has its own advantages and limitations, making them suitable for different applications. This article delves into the differences between vertical vs. horizontal laminar flow cabinets and the factors to consider for choosing the right type.

Understanding Laminar Flow Cabinets

Laminar flow cabinets are specialized equipment designed to provide a clean, particle-free environment by directing filtered air over the workspace in a unidirectional flow. This ensures that contaminants are continuously removed from the working area, protecting sensitive samples, processes, and instruments.

What is Vertical Laminar Flow Cabinets

Vertical laminar flow cabinets are critical tools in laboratory environments where a clean, particle-free workspace is essential. These cabinets provide a sterile zone by directing filtered air in a vertical, downward motion across the work surface, preventing contamination of sensitive samples, instruments, and procedures. Commonly found in pharmaceutical labs, cleanrooms, electronics manufacturing, and microbiology settings, vertical laminar flow cabinets play a key role in maintaining product integrity.

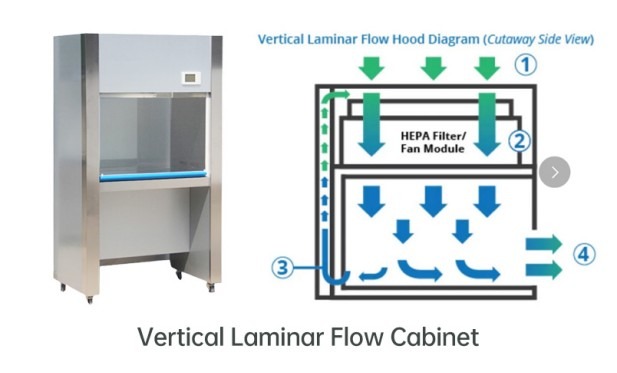

How Do They Work

The operation of a vertical laminar flow cabinet centers on the principle of unidirectional airflow. Ambient air is drawn into the cabinet, passed through a pre-filter and then through a high-efficiency particulate air (HEPA) filter located at the top. This filter removes at least 99.99% of airborne particles as small as 0.3 microns. The filtered air is then blown downward in a laminar (uniform and parallel) flow over the work surface and out through front or bottom openings, thereby sweeping contaminants away from the workspace.

Advantages

- Enhanced Product Protection:The top-to-bottom airflow ensures that contaminants are continuously flushed away from the work surface, providing a highly sterile environment for procedures involving sterile media preparation, tissue culture, or assembly of sensitive components.

- Improved User Safety (Compared to Horizontal Flow): In vertical cabinets, air is directed downward and away from the user’s face, reducing the likelihood of particles being blown directly at the operator. While they do not offer the same level of user protection as biosafety cabinets, this design is a safer alternative to horizontal flow when there is a minimal risk of aerosol exposure.

- Space Efficiency and Tall Equipment Accommodation: Vertical flow cabinets typically have a compact footprint and taller interior clearance, making them suitable for laboratories with limited space. The design also allows easier accommodation of tall glassware or instruments without interfering with airflow.

- Reduced Cross-Contamination Risk:The vertical flow pattern minimizes the lateral spread of contaminants across the workspace, which is beneficial when handling multiple samples or tasks within the same cabinet.

Limitations

- Potential for Airflow Obstruction: Large or improperly placed equipment can obstruct the vertical airflow and create turbulent zones. These disruptions may lead to recirculation of particles or compromised sterility in certain areas of the cabinet.

- Not Suitable for Hazardous Materials: Despite offering improved protection over horizontal flow units, vertical laminar flow cabinets do not provide any containment. They should not be used for handling infectious agents, toxic chemicals, or biological hazards. For such applications, a certified biological safety cabinet is required.

- Limited Operator Protection: While vertical flow helps direct air away from the user, it does not guarantee protection from aerosols or spills. Any procedure involving volatile substances or infectious material poses a risk and falls outside the intended use of these cabinets.

- Maintenance Requirements: To ensure consistent performance, regular maintenance is essential. This includes replacing filters, checking airflow velocity, and inspecting for physical damage. Improper maintenance can compromise the sterile barrier the cabinet is designed to uphold.

What is Horizontal Laminar Flow Cabinets

Horizontal laminar flow cabinets are widely used in laboratories where a clean, sterile working environment is essential to ensure product integrity. These cabinets provide a contamination-free workspace by directing a continuous, unidirectional stream of filtered air horizontally across the work surface, thereby protecting samples and processes from airborne particles. They are commonly used in pharmaceutical, electronic, and optical component handling, as well as microbiological applications where operator protection is not required.

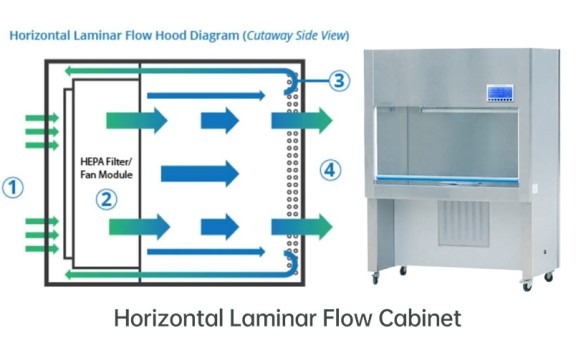

How Do They Work

The defining characteristic of a horizontal laminar flow cabinet is its airflow pattern. Air from the surrounding room is drawn into the cabinet, passes through a pre-filter, and then through a HEPA (High-Efficiency Particulate Air) filter mounted at the rear of the cabinet. Once purified, the air flows forward in a smooth, parallel stream from the rear of the unit directly toward the operator. This steady flow pushes airborne contaminants out of the cabinet and away from the critical working area.

Because the air moves in a horizontal line across the workspace, it creates a consistent, particle-free zone ideal for tasks that require strict control of environmental cleanliness.

Advantages

- Uniform Airflow Over Work Surface: The horizontal airflow provides a consistent and even flow across the entire workbench, which is particularly beneficial when working with multiple small instruments or samples that require uniform protection.

- Minimal Airflow Obstruction: Since the air moves directly from the back to the front, the chances of airflow being disrupted by equipment placed on the work surface are lower than in vertical systems. This helps maintain laminar conditions even during complex tasks.

- Enhanced Visibility and Operator Comfort: Horizontal cabinets offer excellent visibility and easier hand access during precise or delicate procedures. Without overhead airflow, there’s more vertical space, and the lighting is typically more effective.

- Ideal for Sensitive Operations: These cabinets are well-suited for applications like assembling electronic devices, preparing media, or working with non-pathogenic cultures, where contamination control is critical, but personal protection is not necessary.

Limitations

- No Operator Protection: Because filtered air is directed toward the user, horizontal flow cabinets do not provide protection against potentially harmful fumes, aerosols, or infectious agents. This limits their use strictly to non-hazardous materials.

2. Risk of Contamination to the Environment and User: In case of spillage, splashing, or aerosol generation, contaminants can be blown directly out of the cabinet and toward the operator, creating a risk if the materials being handled are not strictly safe.

3. Spatial Requirements: These cabinets usually have a larger footprint than vertical flow units due to the rear-mounted HEPA filter and internal blower. This might be a limitation in labs with restricted space.

4. Positioning Constraints: To maintain laminar flow, items must be carefully placed within the cabinet. Obstructing the rear filter or placing objects too close together can disrupt the airflow and compromise sterility.

Comparison of Vertical vs. Horizontal Laminar Flow Cabinets

Here’s a clear comparison chart highlighting the key differences between Vertical and Horizontal Laminar Flow Cabinets:

| Feature | Vertical Laminar Flow Cabinet | Horizontal Laminar Flow Cabinet |

| Airflow Direction | Top to bottom (vertical, downward) | Back to front (horizontal, toward the operator) |

| HEPA Filter Location | Mounted at the top of the cabinet | Mounted at the rear of the cabinet |

| Workspace Clearance | More vertical space, better for tall equipment | Better horizontal clearance, may limit height for taller items |

| Risk of Airflow Obstruction | Higher — tall items may disrupt airflow | Lower — air flows evenly around most objects on the work surface |

| Operator Protection | Somewhat better — air flows away from face | Minimal — air flows directly toward operator |

| Product Protection | Excellent, depending on airflow integrity | Excellent, uniform airflow over surface |

| Typical Applications | Sterile media prep, tissue culture, non-hazardous aseptic tasks | Electronic assembly, plate pouring, optical equipment handling |

| Footprint and Size | More compact, suitable for smaller labs | Typically requires more depth due to rear-mounted filter |

| Noise Level | Often quieter due to vertical airflow path | Can be slightly louder due to air traveling a longer horizontal path |

| Ease of Access and Visibility | May have slightly reduced visibility due to top airflow | Better visibility and access to workspace |

Choosing Between Vertical vs. Horizontal Laminar Flow Cabinet for Your Laboratory

Selecting between vertical and horizontal laminar flow cabinets requires thoughtful evaluation of various operational and spatial factors. Each design has unique advantages and understanding your lab’s specific needs will help in making the right choice.

- Nature of the Work Being Performed

The type of laboratory work you perform is one of the most critical considerations. If your tasks involve handling non-hazardous materials that require an ultra-clean environment—such as media preparation, plating, or assembling optical components—either cabinet type may suffice. However, if your procedures involve working with large or tall items, vertical laminar flow cabinets may be more appropriate due to their vertical clearance.

On the other hand, if your processes require frequent hand movement, component assembly, or detailed visual tasks, a horizontal cabinet provides better accessibility and visibility across the entire work surface.

- Safety Requirements for Operators and Samples

Neither type of laminar flow cabinet is intended to handle hazardous or infectious materials. However, when it comes to user exposure to airflow, vertical cabinets offer slightly more protection. Since the filtered air moves downward and away from the user, vertical flow cabinets reduce the chance of particles blowing directly toward the face. In contrast, horizontal cabinets push air toward the user, which is less ideal in situations where powders or splashes could become airborne.

If any form of hazardous material handling is involved, neither cabinet is suitable. Instead, a certified biosafety cabinet should be used.

- Workspace Size and Laboratory Layout

The size of your lab space can significantly influence your decision. Vertical laminar flow cabinets typically have a smaller footprint and fit better into tight spaces, making them more convenient in compact lab setups. Their upright design also accommodates taller equipment within the work zone.

Horizontal cabinets, while offering greater visibility and ergonomic access, generally take up more depth due to the rear-mounted filter and airflow components. It’s important to assess your lab’s available bench space and ceiling height before making a decision.

- Equipment Placement and Airflow Dynamics

Airflow uniformity and obstruction are central to the effectiveness of any laminar flow cabinet. In vertical units, large equipment may disrupt the downward airflow and cause turbulence or contamination zones on the work surface. Therefore, it is crucial to minimize objects directly beneath the HEPA filter.

Horizontal cabinets are more forgiving in this regard, as airflow moves smoothly over the work surface from back to front, around most equipment. This makes horizontal models preferable when working with multiple tools or samples simultaneously, where consistent laminar flow across the surface is essential.

- Maintenance and Operational Considerations

Both laminar flow cabinet types require regular maintenance, including filter replacement and airflow validation. However, horizontal cabinets may be slightly more accessible in terms of filter changes due to their rear filter placement. On the other hand, vertical units often have a quieter operation due to the direction of airflow and internal blower configuration.

It’s also important to consider ease of cleaning. Vertical flow surfaces are typically less prone to dust buildup, as the air is directed downward and exits at the base or front. This can simplify routine maintenance in some lab environments.

- Cost and Long-Term Value

While the initial cost difference between the two types may be marginal, operational costs can vary based on space utilization, maintenance frequency, and filter replacement needs. Vertical cabinets may offer better value in space-limited laboratories, while horizontal cabinets could be more cost-effective in environments where ergonomic access and multitasking on the work surface are prioritized.

Final Thoughts

Both vertical and horizontal laminar flow cabinets are effective tools for maintaining cleanliness and product integrity in lab environments. The key lies in aligning the airflow design with your specific laboratory application needs. Vertical laminar flow cabinets offer greater safety and compact design, while horizontal laminar flow cabinets provide consistent airflow and ease of maintenance. Choosing the right type ensures both operational efficiency and a contamination-free workspace.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.