Sample preparation is a critical step in many analytical procedures, especially when working with complex matrices in industries like environmental science, food safety, pharmaceutical development, etc. Among the many sample preparation techniques available, digestion methods which can be used to break down complex samples into a homogenous solution are commonly adopted. Two primary digestion approaches are used: microwave digestion and traditional digestion methods. Understanding their differences of microwave digestion vs. traditional digestion methods, is crucial for choosing the most suitable technique for specific applications.

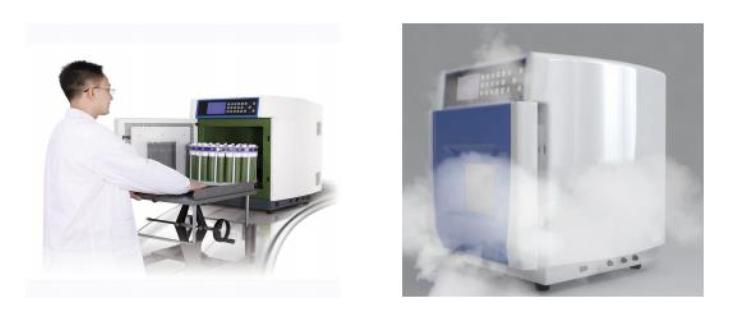

Overview of Microwave Digestion

Microwave digestion is an advanced sample preparation technique used to break down complex matrices into clear solutions for further analysis, often by atomic absorption spectroscopy (AAS), inductively coupled plasma optical emission spectrometry (ICP-OES), or inductively coupled plasma mass spectrometry (ICP-MS). It uses microwave energy to heat acid mixtures inside sealed, high-pressure-resistant vessels, resulting in rapid and efficient digestion.

Microwave digestion systems are often programmable, allowing for precise control over temperature, pressure, and time. This not only improves reproducibility but also enhances safety, as the digestion occurs in specially designed containers that minimize the risk of acid exposure.

| Step | Description |

| 1. Sample and Acid Addition | Place a measured amount of sample into a specialized digestion vessel and add concentrated acids (e.g., HNO₃, HCl, H₂SO₄). |

| 2. Vessel Sealing | Seal the digestion vessel tightly to create a closed, pressure-resistant environment. |

| 3. Microwave Heating | Place vessels in a microwave digestion system; microwave energy rapidly heats the acids and sample under controlled temperature and pressure. |

| 4. Digestion Reaction | Under high temperature and pressure, the acids break down the sample matrix into simple, soluble forms. |

| 5. Cooling Phase | After digestion, the system cools down to reduce internal pressure and allow safe handling. |

| 6. Opening and Dilution | Carefully open the vessels and dilute the digested solution with deionized water or appropriate solvent for analysis. |

Advantages

- Speed: Complete digestion is achieved in minutes to about an hour, compared to several hours needed for traditional methods.

- Enhanced Recovery: Closed-vessel digestion minimizes the loss of volatile elements (e.g., mercury, arsenic).

- High Reproducibility: Automated temperature and pressure control ensure consistent digestion conditions across samples.

- Improved Safety: Enclosed vessels and sophisticated monitoring systems reduce the risk of acid exposure and accidents.

- Low Acid Consumption: Efficient digestion often requires smaller volumes of acid, reducing chemical costs and waste.

- Handling of Difficult Samples: Capable of digesting tough matrices such as soils, biological tissues, polymers, and industrial materials.

Limitations

- High Initial Cost: Equipment and specialized digestion vessels are expensive compared to traditional heating devices.

- Maintenance and Complexity: Systems require regular maintenance, and operators need training to program and troubleshoot the equipment.

- Limited Sample Size: Small sample quantities (typically 0.1–0.5 g) are recommended to avoid excessive pressure buildup.

- Throughput Constraints: Although some systems can process multiple samples at once, they may not meet the needs of very high-throughput labs without multiple units.

- Potential Vessel Wear: Digesting aggressive matrices (e.g., silicates, refractory materials) can degrade vessels over time, leading to additional replacement costs.

Overview of Traditional Digestion Methods

Traditional digestion methods refer to sample preparation techniques where acids and heat are used in open systems (such as on a hot plate, sand bath, or heating block) to break down solid, liquid, or semi-solid samples into a simple, analyzable solution. These techniques have been used for decades across laboratories in environmental analysis, food testing, mining, and chemical research.

Unlike microwave digestion, traditional methods operate under atmospheric pressure, limiting maximum temperatures to the boiling points of the acids used.

How Traditional Digestion Methods Work

| Step | Description |

| 1. Sample Preparation | Place a measured sample into an open container such as a beaker, flask, or digestion tube. |

| 2. Acid Addition | Add concentrated acids (e.g., nitric acid, sulfuric acid, hydrochloric acid) directly to the sample. |

| 3. Heating | Heat the sample-acid mixture on a hot plate, sand bath, or block digester under atmospheric pressure. |

| 4. Digestion Reaction | The acids react with the sample, gradually breaking down the matrix into soluble components. |

| 5. Evaporation (if needed) | Sometimes the solution is heated further to reduce volume and concentrate the digest. |

| 6. Cooling and Dilution | Allow the digest to cool, then dilute with water or another solvent for subsequent analysis. |

Common Types of Traditional Digestion Methods

- Hot Plate Digestion: Open beakers on heated plates; suitable for simple matrices.

- Sand Bath Digestion: Beakers or flasks heated indirectly in hot sand; provides more even heating.

- Block Digestion: Samples placed in a metal block with wells; ensures more uniform heating across multiple samples.

Advantages

- Low Equipment Cost: Requires only basic laboratory equipment, such as hot plates or heating blocks.

- Simple Operation: Easy to perform without needing sophisticated programming or automation.

- Flexibility: Operators can adjust acid volume, temperature, and digestion time in real time based on sample behavior.

- High Throughput Potential: Large batches of samples can be processed simultaneously, depending on available space.

- Minimal Technical Training Needed: Basic laboratory training is sufficient for most traditional digestion methods.

Limitations

- Longer Digestion Time: Complete digestion can take several hours to even overnight.

- Lower Safety: Open acid systems expose users to harmful fumes and splashes, increasing health and safety risks.

- Loss of Volatile Elements: Elements like mercury, selenium, and arsenic may evaporate during open digestion, leading to inaccurate results.

- Lower Temperature Control: Limited ability to control and monitor precise digestion temperatures, which can affect reproducibility.

- Inconsistent Results: Operator skill, attention, and environmental factors (like airflow) can significantly impact digestion quality.

- High Acid Consumption: Often requires large volumes of acids, leading to higher costs for chemicals and increased waste handling.

Key Differences Between Microwave Digestion vs.Traditional Digestion Methods

| Aspect | Microwave Digestion | Traditional Digestion |

| Heating Method | Microwave energy heats sealed vessels internally and rapidly. | External heating (hot plate, sand bath, block) under atmospheric pressure. |

| Pressure and Temperature | High pressure and temperature inside sealed vessels (up to ~300°C and 100 bar). | Limited to boiling point of acids; operates at atmospheric pressure. |

| Digestion Speed | Fast: usually completed in 20–60 minutes. | Slow: can take several hours or overnight. |

| Safety | High: closed vessels minimize acid fumes and splashes. | Lower: open systems expose users to acid vapors and risks. |

| Recovery of Volatile Elements | Excellent: volatile elements are preserved inside closed vessels. | Poor: volatile elements may evaporate and be lost. |

| Sample Size | Small (typically 0.1–0.5 g per vessel). | Larger sample quantities possible depending on container size. |

| Equipment Cost | High: requires microwave digestion systems and specialized vessels. | Low: basic heating equipment like hot plates and beakers suffice. |

| Ease of Use | Requires training to operate systems and program conditions. | Simple operation; easier for beginners. |

Choosing Between Microwave Digestion vs. Traditional Digestion Methods

When deciding between microwave digestion and traditional digestion methods, several important factors should be considered.

- Sample Type and Complexity

Choosing the right digestion method starts with understanding the sample. For complex matrices or those containing volatile elements, microwave digestion is often preferred because it ensures complete breakdown while preserving sensitive analytes. Traditional digestion methods can be sufficient for simpler samples where ultra-precise recovery is not essential.

- Time Efficiency

If rapid sample preparation is needed, microwave digestion stands out. It dramatically reduces digestion times, often completing in under an hour, whereas traditional methods can require several hours or even overnight heating.

- Safety Considerations

Safety is a major factor. Microwave digestion systems operate in sealed vessels, minimizing the release of toxic fumes and exposure to acids. Traditional digestion methods, using open systems, pose greater risks to operators through direct contact with acid vapors.

- Cost and Equipment Investment

Budget constraints can heavily influence the choice. Microwave digestion demands a significant upfront investment in specialized equipment, while traditional digestion only requires basic laboratory tools like hot plates or heating blocks, making it more cost-effective initially.

- Sample Throughput

For laboratories handling large volumes of samples, traditional digestion can accommodate bigger batches more easily. However, modern microwave digesters with multiple vessels now offer competitive throughput, balancing speed with volume.

- Precision and Reproducibility

Microwave digestion offers highly reproducible and precise results due to the controlled environment of temperature and pressure. Traditional digestion methods are more prone to variability depending on operator technique and manual control.

- Operator Expertise

Microwave digestion systems require trained personnel who can program digestion parameters and handle pressurized vessels safely. In contrast, traditional digestion is easier to teach and operate, making it more suitable for laboratories with less experienced staff.

- Infrastructure Requirements

Microwave digestion systems need reliable power supply, proper lab space, and in some cases, dedicated ventilation setups. Traditional digestion setups are simpler, needing only basic fume hoods and heating equipment, making them ideal for labs with limited infrastructure.

- Environmental Impact

Environmental sustainability is another important factor. Microwave digestion typically uses less acid and generates less chemical waste, aligning better with green chemistry practices. Traditional methods often consume larger volumes of acid, resulting in greater waste.

Summary

Both microwave digestion and traditional digestion methods are commonly used in analytical laboratories. Microwave digestion offers clear advantages in speed, reproducibility, safety and accuracy, making it the method of choice for many modern labs. However, traditional digestion remains a viable option for simple applications, low-budget operations, or situations where ultra-trace analysis is not required. Choosing the right digestion method ultimately depends on the specific needs of the application, available resources and the analytical goals of the laboratory.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.