In the field of clinical microbiology, maintaining a sterile environment is critical for accurate diagnostic outcomes and safe laboratory practices. Laminar flow cabinets play a pivotal role in achieving this goal by ensuring contamination-free handling of specimens, cultures, and reagents. These cabinets are designed to create a controlled workspace that minimizes the risk of microbial contamination. This article explores the various types of laminar flow cabinets and their critical functions and benefits in clinical microbiology.

What is Laminar Airflow?

Laminar flow, also known as streamline flow, describes a condition where a fluid (in this case, air) moves in parallel layers, with no disruption between the layers. The velocity of the air at any given point remains constant in both magnitude and direction. Imagine a smooth, unwavering stream of water; this is analogous to laminar airflow. In contrast to turbulent flow, which is characterized by chaotic and irregular movement with eddies and cross-currents, laminar flow minimizes the mixing of air streams and the potential for airborne particles to be introduced into the clean workspace. Laminar flow cabinets utilize this principle to maintain sterility.

HEPA Filtration

The creation and maintenance of laminar airflow are intrinsically linked to the function of High-Efficiency Particulate Air (HEPA) filters. These filters are designed to remove an exceptionally high percentage of airborne particles. According to accepted standards, a HEPA filter must remove at least 99.97% of particles with a diameter of 0.3 micrometers (µm). This size is considered the “most penetrating particle size” (MPPS), meaning particles smaller or larger than 0.3 µm are generally captured with even higher efficiency.

HEPA filters are typically composed of a mat of randomly arranged fibers (usually fiberglass) that form a dense network. Particles are trapped through a combination of mechanisms: interception (particles following an airflow streamline come within one fiber radius of a fiber and adhere to it), impaction (larger particles, due to their inertia, cannot follow the curving streamlines of the air and collide directly with the fibers), and diffusion (very small particles exhibit random Brownian motion, increasing their likelihood of colliding with fibers).

The HEPA filter is the heart of the laminar flow cabinet, ensuring that the air passing over the work surface is virtually free of microbial contaminants and particulate matter.

Airflow Patterns

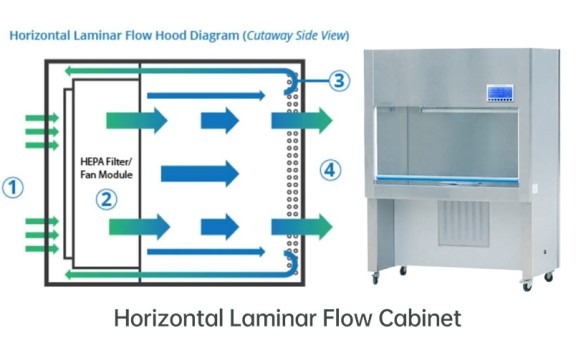

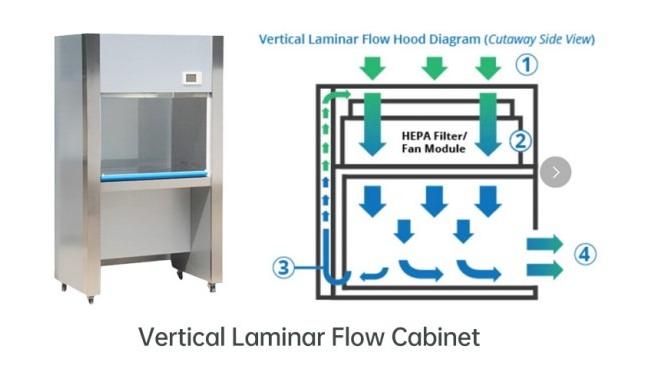

Laminar flow cabinets employ two main airflow patterns: horizontal and vertical. These patterns determine the direction of airflow and influence the cabinet’s suitability for specific applications. Horizontal airflow moves air from the back of the cabinet towards the operator, while vertical airflow directs air from the top downwards to the work surface.

Let’s know more details about the types of laminar flow cabinets.

Types of Laminar Flow Cabinets

Based on the direction of the laminar airflow, these cabinets are broadly categorized into two main types: horizontal laminar flow cabinets and vertical laminar flow cabinets. Each type possesses distinct design features, advantages, and disadvantages that make them suitable for specific applications within the clinical microbiology laboratory.

Horizontal Laminar Flow Cabinets:

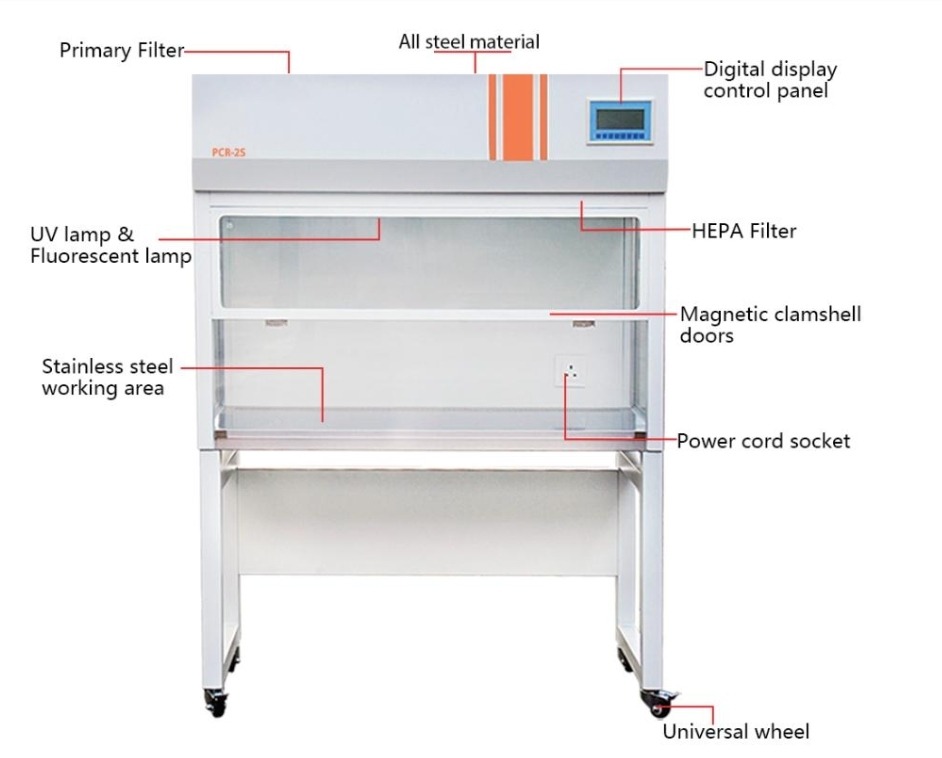

Horizontal laminar flow cabinets are designed with the HEPA filter located at the back of the work area. A fan draws ambient air, passes it through a pre-filter to remove larger particles, and then forces it through the HEPA filter. The resulting ultra-clean air then flows in a horizontal stream across the work surface, directly towards the operator. The front of the cabinet is typically open, allowing the operator to access the work area.

| Feature | Horizontal Laminar Flow Cabinets | |

| Advantages | Simpler Design | Generally has a less complex construction. |

| Easier Maintenance | Often easier and less costly to maintain. | |

| Unobstructed Work Area | Can provide a clearer view and more open working space. | |

| Lower Initial Cost | Typically has a lower purchase price. | |

| Enhanced Product Protection | Provides a clean environment for sensitive materials. | |

| Disadvantages | Potential for Cross-Contamination (within cabinet) | Horizontal airflow can carry downstream contaminants to upstream areas. |

| Operator Exposure | Operator is directly in the path of the airflow from the work area. | |

| Turbulence from Large Objects | Large items can disrupt the horizontal airflow. |

Vertical Laminar Flow Cabinets

Vertical laminar flow cabinets feature a HEPA filter located above the work area. Air is drawn in from the top (or sometimes the front), passed through a pre-filter and then the HEPA filter, and directed vertically downwards across the work surface. The air then exits through perforations in the base of the cabinet or at the front opening.

| Feature | Vertical Laminar Flow Cabinets | |

| Advantages | Enhanced Product Protection | Provides a high level of protection against environmental contamination. |

| Reduced Operator Exposure | Airflow directs contaminants away from the operator. | |

| Lower Cross-Contamination Risk (within cabinet) | Downward airflow reduces the risk of downstream contamination affecting upstream materials. | |

| Disadvantages | Turbulence from Large Objects | Objects on the work surface can disrupt the downward airflow. |

| More Complex Design | Generally has a more intricate construction. | |

| More Complex Maintenance | Often more difficult and costly to maintain. | |

| Higher Initial Cost | Typically has a higher purchase price. |

Horizontal vs Vertical Laminar Flow Cabinet

| Feature | Horizontal Laminar Flow Cabinet | Vertical Laminar Flow Cabinet |

| Airflow Direction | Horizontal (towards operator) | Vertical (downwards) |

| HEPA Filter Location | Back of work area | Above work area |

| Operator Exposure | Direct exposure to airflow | Reduced exposure |

| Cross-Contamination Risk (within cabinet) | Higher (downstream to upstream) | Lower (downwards away from materials) |

| Design Complexity | Simpler | More complex |

| Maintenance | Generally easier | Potentially more complex |

| Initial Cost | Generally lower | Generally higher |

| Primary Protection | Product | Product (and some operator benefit) |

| Typical Uses | Non-hazardous materials, media prep | Potentially infectious materials, sensitive assays |

The choice between a horizontal and a vertical laminar flow cabinet in a clinical microbiology laboratory depends on a careful evaluation of the specific applications, the level of product protection required, and considerations for operator safety. While horizontal flow cabinets offer simplicity and lower cost for certain non-hazardous applications, vertical flow cabinets provide enhanced product protection and reduced operator exposure for more sensitive procedures. Understanding these distinctions is crucial for selecting the most appropriate equipment to maintain the integrity of microbiological work.

Applications and Functions of Laminar Flow Cabinets in Clinical Microbiology

Laminar flow cabinets are indispensable tools within the clinical microbiology laboratory, providing a controlled and sterile environment crucial for a wide array of applications. Their primary function is to minimize the risk of contamination, thereby ensuring the integrity and accuracy of diagnostic procedures.

- Aseptic Techniques:

Laminar flow cabinets are fundamental for performing aseptic techniques, which are essential to prevent the introduction of unwanted microorganisms into cultures and experiments. The constant flow of HEPA-filtered air minimizes the settling of airborne particles and reduces the risk of contamination during critical manipulations.

This includes inoculation of culture media (agar plates, broths), subculturing of microorganisms to maintain pure cultures, preparation of microbial suspensions for testing, and performing differential staining procedures where maintaining sample purity is vital.

- Media Preparation:

The preparation of sterile culture media is a cornerstone of clinical microbiology. Laminar flow cabinets provide a clean environment for various stages of this process, ensuring that the media itself is free from contaminants that could affect microbial growth and subsequent analysis.

This involves weighing out dehydrated media components, dissolving them in sterile water, dispensing sterile media into Petri dishes or tubes, and performing sterile filtration of heat-sensitive media components.

- Handling of Non-Hazardous Samples:

For procedures involving non-pathogenic or low-risk microorganisms and samples, laminar flow cabinets offer a protected workspace to prevent environmental contamination that could interfere with analysis.

This can include setting up biochemical tests for microbial identification, performing agglutination assays, preparing slides for microscopic examination, and conducting quality control checks on media and reagents.

- Handling of Potentially Hazardous Samples (with appropriate cabinet type):

While it is crucial to emphasize that laminar flow cabinets are not biological safety cabinets designed for operator protection against biohazards, vertical laminar flow cabinets can offer a degree of containment for procedures involving potentially infectious but non-aerosolizing materials. The downward airflow helps to move any released particles away from the operator, primarily protecting the product.

This might include careful manipulation of primary clinical specimens before they are inoculated onto culture media, or the preparation of certain diagnostic reagents from potentially infectious sources, always with strict adherence to safety protocols and recognizing the limitations of these cabinets for biohazard containment. It is paramount to reiterate that procedures generating aerosols of biohazardous agents must be performed in certified biological safety cabinets.

- Equipment Setup and Preparation:

Maintaining the sterility of equipment and supplies used in microbiological procedures is vital. Laminar flow cabinets provide a clean area for setting up and preparing such items.

This includes assembling sterile filtration apparatus, preparing sterile pipettes and other glassware, arranging components for molecular diagnostic assays, and packaging sterilized materials for use.

Final Thoughts

Laminar flow cabinets serve a multifaceted role in the clinical microbiology laboratory. Their applications extend across a wide range of essential procedures, all centered around the fundamental function of maintaining a sterile environment. From the basic inoculation of media to the more complex preparation of reagents and handling of specific sample types (with appropriate caution), these cabinets are critical for ensuring the accuracy, reliability, and ultimately the clinical utility of microbiological testing. However, it is crucial for laboratory personnel to understand the specific capabilities and limitations of laminar flow cabinets, particularly in distinguishing them from biological safety cabinets when handling potentially hazardous materials. Both biological safety cabinets and laminar flow cabinets are available in Drawell, please feel free to contact us when you need.

Related Products Recommendation

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.