Steel is the foundation for modern-day infrastructure. From towering buildings to automobiles we drive, it the strength and flexibility of steel is due to its exact chemical composition. Although many elements are responsible for steel’s properties, carbon sulphur analyzers are one of them. Carbon sulfur analyzers play an essential function in monitoring and regulating these elements, which ensures steel’s durability, performance and conformity to standards. This article examines how these analyzers improve steel production in every step starting from the initial inspection of raw materials through final quality control.

Why Carbon Sulfur Analysis is Paramount in Steel Production

In the highly competitive world of steel manufacturing precision isn’t something to be desired, it’s an absolute requirement. The different levels of sulfur and carbon in steel are more than just numbers on a document; they define the nature of the final product. A lack or excess of either could cause major quality issues, which affect all aspects of structural quality to the ease of fabrication. Understanding the impact of these issues can be the initial step towards realizing the importance of reliable carbon sulfur analyses.

Impact of Carbon on Steel Properties:

Carbon is steel’s main hardening agent. It transforms iron’s soft and ductile substance into the tough, versatile alloy we are familiar with as steel. Carbon content directly affects steel’s strength as well as its hardness and weldability.

For instance, low carbon steels (typically less than 0.25 percent carbon) are ductile and can be easily made and welded, which makes them suitable for car bodies as well as structural beams. When the carbon content rises in medium carbon steels (0.25-0.60 percent carbon) and the steel becomes stronger and more durable, which is ideal for railway tracks and machine components, but it becomes less ductile and difficult to weld. The high-carbon steels (over 0.60 percent carbon) are extremely hard and wear-resistant, which is why they are used in springs and tools however they can be very brittle and hard to work with. Without accurate carbon sulfur analysis steel producers are operating blindly, putting themselves at risk of manufacturing of steel that is either too soft to support the intended load or is too fragile to withstand the demands of processing or. The ability to accurately measure carbon levels enables manufacturers to adapt the steel to the specific requirements, ensuring maximum performance and security.

The Detrimental Effects of Sulfur in Steel:

In contrast to carbon dioxide, sulfur can be generally regarded as an undesirable component in the majority of steel-related applications. Even at very low levels the element can cause negative effects on the properties of steel’s mechanical properties especially when temperatures are elevated.

The most well-known problem that sulfur causes most commonly is “hot shortness.” This happens when sulfur mixes with iron, forming iron sulfur (FeS) which has an lower melting point than steel. When working with hot temperatures, such as rolling or forging, the iron sulfide inclusions begin to melt and form liquid films near the edges of the grain. The steel is weakened, which causes it to crack and break, resulting in substantial losses in material and downtime for production. For instance, even levels that are as minimal as 0.05 percent could make steel very vulnerable to hot shortness. Additionally, sulfur may lower the impact strength and ductility as well as corrosion resistance. Although small and controlled additions of sulfur may be used to make “free-machining steels” (as manganese sulfur inclusions function like chipbreakers) In the majority of applications sulfur is a contaminant that must be eliminated. The accuracy of infrared analysis of sulfur are crucial to avoid these costly flaws and to ensure the quality in the finished product.

Process Control and Optimization:

Beyond understanding the impact of individual elements the continuous analysis of carbon sulfur is crucial to dynamic control of processes and optimization in the plant for steel. Modern steelmaking isn’t an unchanging process. It is constantly adjusted that are based on real-time information.

For instance when desulfurization is taking place in the ladle furnace operators require immediate feedback on the sulfur levels to know if enough desulfurizing substances have been used. A fast analysis of sulfur and carbon could give results in less than one minute, which allows for rapid adjustments instead of waiting for laboratory results which may take much longer. The real-time feedback helps reduce the waste of materials from over-treatment. It also cuts down on energy use by avoiding unnecessary reheating and reduces the overall time from tap to tap. In essence, it turns the process from a reactive one to an active one, leading to significant efficiency and a steady quality of the product.

Optimizing Steel Production Through Carbon and Sulfur Analyzers

The carbon and sulfur analyzers are essential for modern-day steel manufacturing, providing the precise control of the chemical composition of steel at each stage in the production process. They provide real-time, precise information on sulfur and carbon amounts, analyzers can help companies optimize their operations, increase the quality of their products and minimize the amount of waste. Let’s examine how they’re utilized throughout the process of making steel:

Raw Material Inspection

Before production of steel begins raw materials like coke, iron ore and scrap metal need to satisfy stringent quality standards. The variations in sulfur and carbon levels can affect the steelmaking process as well as final product quality.

Carbon in the Iron Ore The low levels of carbon in the raw ore allow for better control in the melting phase.

In Scrap Metal A high concentration of sulfur in scrap causes fragility, requiring careful mixing and processing.

A study at a steel plant that was mid-sized revealed that screening raw materials prior to processing for sulfur decreased the rejection rate by 15 percent, thereby saving an annual $200,000 in materials wasted.

| Material | Carbon (%) | Sulfur (ppm) | Action Required |

| Iron Ore | <0.1 | 50-150 | It is suitable for use. |

| Scrap Metal | 0.1-2.0 | 150-300 | Blend with materials that are low in sulfur. |

Melt Shop Operations

In the process of melting, raw materials transform into molten steel and their chemical composition undergoes dramatic modifications. Analyzers for carbon or sulfur are able to monitor the changes in real-time.

In the refining and melting phases in the process, the sulfur and carbon concentration of the molten bath is always changing when impurities are eliminated as alloying components are added. For example, in an EAF oxygen lancing process, oxygen is employed to decarburize melt. Operators need frequent, almost instantaneous, feedback on carbon levels to control this process precisely and avoid over-decarburization, which would require adding expensive carbon back into the melt. Also, an accurate analysis of sulfur helps to control the process of desulfurization. If bath samples show sulfur levels are too high it is possible to add additional calcium or another desulfurizing agent.

In the absence of traditional laboratory results, which can take up to 15 minutes, could cause wasted furnace time and the potential for over-processing. With an analyzer that can measure sulfur and carbon that can provide results in just 40-60 seconds it is possible to make adjustments at the same temperature which significantly reduces the time from tap to tap and increasing overall efficiency in the melting shop.

A steel company has reported a reduction of 10% in energy consumption by using real-time analysis of sulfur and carbon to optimize their electric arc furnace operation.

Ladle Metallurgy and Secondary Refining

Following the initial melting process, the molten steel usually undergoes refining in ladle-metallurgy furnaces (LMFs) or vacuum degassers. This process is vital for fine-tuning the steel’s chemical composition as well as removing impurities that remain and achieving exact specifications prior to casting.

In the LMF The exact adjustments are made to get the ideal levels of sulfur and carbon, along with the other elements that alloy. This is often the initial stage of deep desulfurization. A sulfur analyzer infrared is an essential tool in providing fast and precise readings to aid in the inclusion of desulfurizing slags or alloys. For instance, if specific steel grade has extremely low sulfur (e.g., <0.005%) periodic tests are required. Without a rapid analysis the ladle could remain idle, losing heat and using energy as users wait for external laboratory results. The carbon and sulfur analyzer on site provides immediate confirmation that the steel meets the rigorous standards, minimizing the amount of time held and making sure that energy efficiency is maintained.

Through strict control manufacturing facilities can ensure the same quality of steel, which is especially crucial in high-strength constructions like skyscrapers or bridges.

Continuous Casting

Continuous casting is that involves the solidification of molten steel into blooms, billets, or slabs. The consistency of the chemical composition at this process is crucial to prevent internal defects, surface cracks, as well as segregation.

When the molten steel is pumped through the ladle to the tundish before being poured into the mold for casting, changes in sulfur or carbon can cause quality issues with the final product. For example that uncontrolled sulfur fluctuations could increase macro-segregation, which can result in inconsistent properties in the casting product. Although direct analysis of the process of casting is difficult but the ability to analyze quickly of sulfur and carbon analyzers guarantees that the steel that is being poured into the machine is meeting its compositional goals at the metallurgy ladle stage. Any alterations that are detected immediately prior to casting can trigger corrective actions that could include redirecting the heat to a new production line or performing a additional treatment, thus preventing the production of material that is not in compliance with specifications which could be later removed or reduced. This proactive method can help save significant expenses associated with re-melting and making substandard materials.

A major steel mill cut defects for their cast process by 8 percent by incorporating sulfur analyzers infrared into the quality management system.

Final Product Quality Control

After the steel has been forged and subsequently processed via the process of rolling, forging or forging a final check of the chemical composition of the steel is usually required. This is the final step prior to the steel being delivered to the customers.

Carbon sulfur analysis makes sure that each batch of coil or plate conforms to the exact specifications set with the client and complies with industry standards applicable to the product (e.g., ASTM, ISO). This is essential to ensure traceability and certification. For instance, an automobile manufacturer might need steel that has a specific Carbon range to be used for the body panel in order to guarantee paint adhesion and formability. For a building project, it might be necessary to use structural steel that is guaranteed to have low sulfur levels to guarantee the weldability of the steel and its resistance to brittle fracture. Any deviation discovered in this process could result in the rejection of the whole batch, costing the steel manufacturer millions. With a exact carbon sulfur analyses producers can assure their clients and ensure their credibility for high-quality and consistent products and establishing confidence in their product.

Through the integration of analysis of sulfur and carbon throughout the manufacturing process steelmakers have a monopoly on the quality of their product along with operational efficiency and environmental conformity. These analyzers do not just protect quality of the steel, they also help in reducing manufacturing costs which makes them an important investment in the future of manufacturing steel.

Choosing the Right Carbon Sulphur Analyzer: What to Consider

When looking at carbon and sulfur analyzers there are a variety of technical specifications as well as operational factors will guide your selection. These aspects directly affect the efficiency of the analyzer, its accessibility and its suitability for the harsh steel manufacturing environment.

Key Features to Look For:

| Aspect | Key Considerations | Why It Matters |

| Sensitivity | The analyzer should be able to identify both low and high levels of sulfur and carbon precisely. | Accurate measurements are crucial to ensure quality control and conformity with industry standards. |

| Speed | Make sure you have quick analysis time for real-time decision making. | Reduces production interruptions and improves the efficiency of operations. |

| Reliability | Select analyzers that are known for their consistent performance and low maintenance requirements. | In the event of equipment failure, it can delay production and add costs. |

| Integration Capability | Check compatibility with current systems that are compatible with existing systems, like laboratory production equipment or setups inline. | seamless integration facilitates seamless workflows, and also reduces the need for expenditures in infrastructure. |

| User-Friendliness | Prioritize your equipment using intuitive software and easy maintenance needs. | This reduces the amount of time spent training operators and decreases errors made by users. |

| Cost and Value | Compare the cost to advantages and features that will last for a long time. | An economical solution that balances the initial investment with durability and performance. |

Select an A reliable Carbon Sulphur Analyzer Manufacturers:

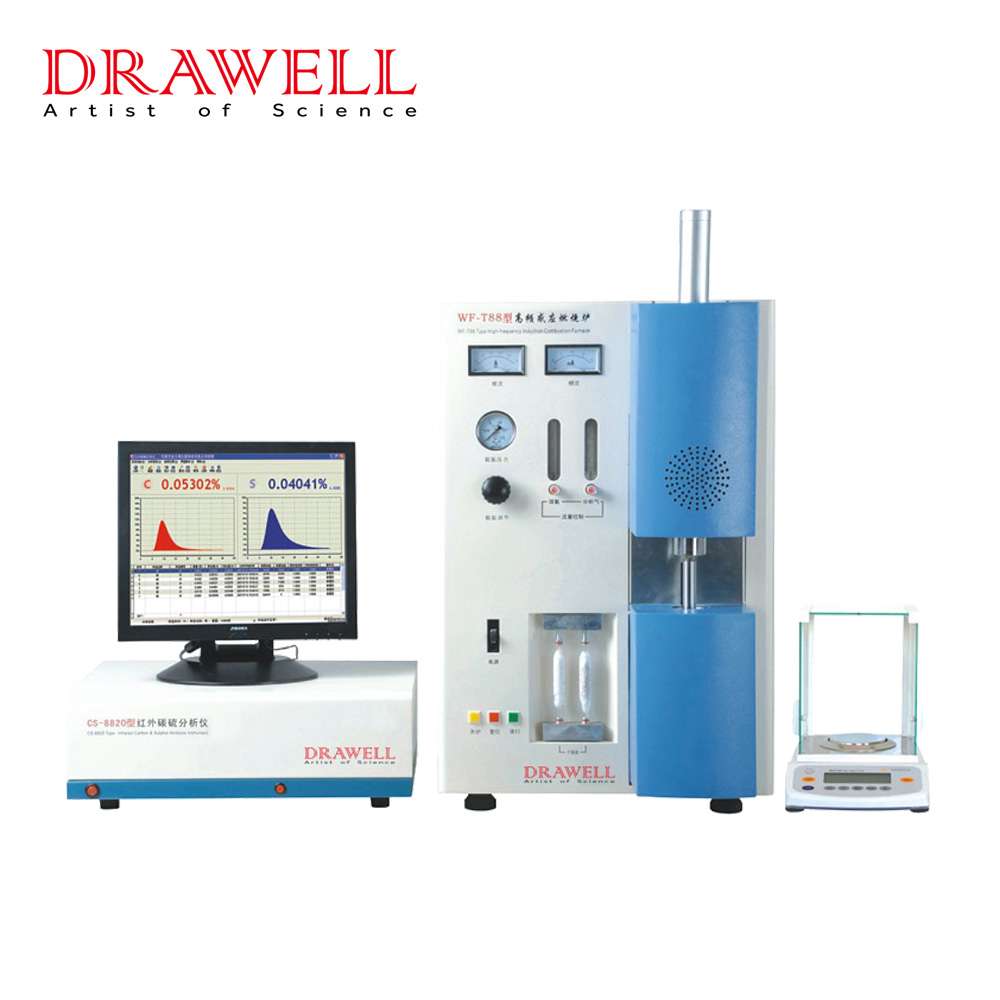

The right choice of manufacturer is vital to ensure that the carbon sulfur analyzer you choose meets the stringent demands of the steel industry. Drawell is a reputable and innovative supplier of analytical solutions that offer advanced analyzers that are designed for accuracy as well as speed and reliability. Their cutting-edge technologies, easy-to-use designs and custom solutions are designed to meet the unique demands of steel makers. With a worldwide reputation for high-quality, extensive support services and a commitment towards sustainable development, Drawell ensures long-term value and seamless integration into manufacturing workflows. By choosing Drawell it’s not buying an analyzer, but investing in accuracy, efficiency and even achievement.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.