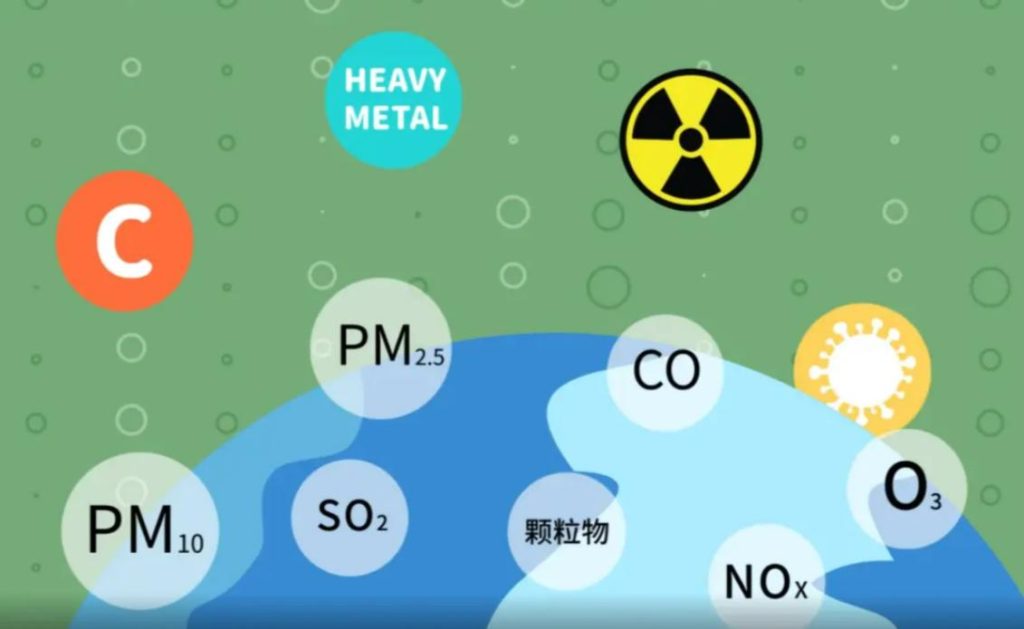

From the widespread existence of carbon dioxide (CO2) which has a profound impact on global climate to the nefarious threat of volatile organic substances (VOCs) which affect the quality of air in your area and the health of humans monitoring the gas phase pollutants has become a pressing and complicated task. The traditional methods for gas analysis are useful, but they often fail to keep up with the varying and changing nature of airborne threats. Imagine having to recognize as well as quantify hundreds of substances in a single swath of air. That’s an immense problem. Fourier Transform Infrared (FTIR) spectrometer is now a powerful and versatile instrument in this field. We will explore the ways FTIR changes the way gas analysis is conducted and its use in the monitoring of pollution, and its benefits over the traditional methods.

What is FTIR for Gas Analysis?

FTIR is a method which detects the absorption of light in the infrared spectrum across an extensive spectrum. Utilizing Fourier transform mathematics, it efficiently processes data to create detailed spectra for gas mixtures.

Infrared absorption forms the core for FTIR technology. Molecules absorb light infrared at specific wavelengths, which correspond to their own unique frequency of vibration. The absorption produces an “fingerprint” that identifies and analyzes gases.

Key Components of an FTIR Gas Analyzer:

| Component | Description | Function |

| Infrared Light Source | It emits a variety of radiation infrared. | It is the first infrared light required for gas absorption measurements. |

| Interferometer | Splits and recombines light to create different pathways. | Modulates the infrared light beam to create an interferogram that is then processed into spectrums. |

| Sample Cell | A space enclosed that contains the gas to be analysed. | This allows the infrared light be absorbed by the sample of gas permitting absorption. |

| Detector | Captured the infrared light that is transmitted. | Converts the signal from infrared into an electrical signal that can be processed and interpretation. |

| Data Processing Unit | Software and hardware are included to analyze. | Conducts Fourier Transform calculations and displays the gas composition and concentration. |

| Optical Filters | Utilized in specific settings to increase the precision of your setup. | It is able to isolate relevant wavelengths, which improves measurement precision for specific gas detection. |

FTIR in Environmental Gas Pollutants Monitoring

The capacity for FTIR gas analyses to deliver accurate and quick information makes it an essential instrument for monitoring environmental conditions that can address a broad range of contaminants.

Carbon Dioxide (CO2) Monitoring using FTIR

Carbon dioxide is a major greenhouse gas and accurate measurement of it is essential for climate research as well as industrial emissions tracking or even for in the quality of indoor air. While NDIS (Non-Dispersive Infrared) sensors can be found in the field of CO2, advanced FTIR analyzers are the most robust and versatile solution, especially in the event that other gasses are present, or where precision is essential.

For instance, in the case of industrial emissions from stacks the infrared CO2 analyzer that is based on FTIR could accurately quantify CO2 along with other combustion products, such as carbon monoxide, water vapor and nitrogen oxides even in volatile gas streams. A case study at power plants showed that Continuous emission monitoring systems (CEMS) that incorporates an FTIR analyzer can accurately determine CO2 concentrations that range between 3% and 15%, with just 2% variance from the reference method and simultaneously monitor other pollutant levels. In the indoor air quality area where CO2 levels are a measure of the efficiency of ventilation portable gas analyzers FTIR offer real-time data to improve HVAC systems such as in schools or office buildings, where levels of CO2 higher than 1000ppm may be a sign of poor ventilation and can result in a decline in cognitive function.

Volatile Organic Compounds (VOCs) Detection using FTIR

Volatile Organic Compounds (VOCs) are a broad category of chemicals that are released by paints, solvents and fuels industrial processes, as well as natural sources. A large portion of VOCs are harmful pollutant to the air (HAPs) which contribute to the formation of smog and posing serious health hazards. Detection and identification of these substances accurately is a major problem in environmental monitoring.

FTIR excels as an VOCs gas detector because of its unbeatable precision. Think about a chemical manufacturing facility’s fenceline monitoring. A conventional photoionization detector (PID) may inform you that “total VOCs” are present however it is unable to distinguish between harmless terpenes in close trees, and carcinogenic benzene that has come from leaks in the process. A FTIR gas analyzer can determine and quantify the presence of specific VOCs such as benzene, toluene as well as the xylene (BTX) formaldehyde Acetone, and other complex chlorinated hydrocarbons simultaneously. This allows for instant determination of the source of the emission as well as targeted remediation.

Here’s an example of this of a remediation plan in an industrial facility that was once a site for production using a handheld FTIR analysis device was employed to trace VOC emission plumes arising from soil that was contaminated. In one specific area that was analyzed, the FTIR detected unexpectedly high levels in vinyl chloride (a known carcinogen) at levels of 500 ppb and the chemical trichloroethylene (TCE) with a concentration of 800 ppb. The detailed information on site enabled the remediation team to rapidly adjust their plans by implementing localized vapor extraction systems exactly in the areas where the highest concentrations of TCE were identified, greatly speeding up the process of cleaning and minimizing risk of exposure for people working in the area and communities nearby. Without the precision of FTIR this distinct risky substances might have been missed or missed by detectors that were less sophisticated.

Air pollutants

Other Environmental Gas Phase Pollutants

The benefits of gas FTIR goes beyond VOCs and CO2. It’s a powerful instrument for monitoring a broad range of other important environmental gases.

- The Nitrogen Oxides (NOx) and Sulfur Dioxide (SO2): The two most important elements of acid rain as well as smog. FTIR can accurately analyze these substances in industrial stacks.

- Ammonia (NH3): A typical pollutant that is a result of agricultural activities and industrial processes that contribute to the formation of particulate matter.

- Hydrogen Chloride (HCl) and Hydrogen Fluoride (HF): Hydrogen Fluoride (HF): Highly toxic and corrosive gases that are commonly used as industrial emission sources (e.g. the incinerators).

- Methane (CH4): A powerful greenhouse gas that is monitored in landfills natural gas facilities as well as in agricultural environments.

This capability is extensive, making the FTIR a valuable instrument to ensure Environmental compliance and research into air quality, as well as emergencies in which multiple contaminants could be in the air.

Evaluation of Other Analysis Methods

Although FTIR has many advantages however, it is essential to comprehend its role in comparison to other techniques for gas analysis especially in relation to conventional infrared gas analyzers.

| Method | Key Features | Advantages | Limitations |

| FTIR (Fourier Transform Infrared) | Simultaneous multi-gas detection; real-time analysis; non-destructive. | Flexible, high sensitivity No need for consumables, a wide gas spectrum. | More expensive initial cost, sensitivity to the environment. |

| Gas Chromatography (GC) | Separates gases for analysis on their own and requires a the use of a carrier gas. | High precision, great for mixing complex substances. | Time-consuming, requires extensive sample preparation. |

| Traditional IR Analyzers | Single gas detection using narrow-spectrum infrared. | Simple operation, low cost. | Only limited to certain gases Not suitable for detection of several gases. |

| Electrochemical Sensors | Utilizes chemical reactions to measure gas concentrations. | Small, inexpensive, and suitable for toxic gases that are specific to NO2 or CO. | Limits the lifespan and is sensitive to cross-interference. |

| Photoacoustic Spectroscopy (PAS) | The measurement of sound waves caused through gas absorption caused by light modulated. | High sensitivities for gas analysis in trace gases. | Limited in the ability to detect multiple gases at once. |

| Mass Spectrometry (MS) | Gas molecules are ionized to determine the mass-to-charge ratio. | Highly precise, ideal for rare gasses. | Costly, requires a controlled atmosphere and a complex operation. |

FTIR stands out due to its versatility and efficacy even though it needs meticulous calibration and ongoing maintenance. Techniques such as gas chromatography and traditional IR analyzers are still useful in specialized situations. By coordinating all the features of every technology to your particular requirements and requirements, you can guarantee accurate and efficient gas monitoring.

Final Thoughts

Recent advancements have improved the capabilities of FTIR. Gas analyzers that are portable FTIR are now able to combine the highest sensitivity and mobility, making them perfect for field work. The integration with IoT platforms enables remote monitoring and analysis of data, while advances in detectors have enhanced the accuracy of their instruments and cut expenses.

FTIR is now a vital tool for analyzing the effects of environmental gases providing unparalleled flexibility and precision. If it’s monitoring CO2 emissions or the detection of VOCs and other pollutant, FTIR provides real-time insights that allow governments and industries to make decisions effectively. As technology develops and advances, the potential of FTIR to address the environmental challenges facing the world will continue to increase.

Let’s embrace FTIR to create cleaner and healthier living.

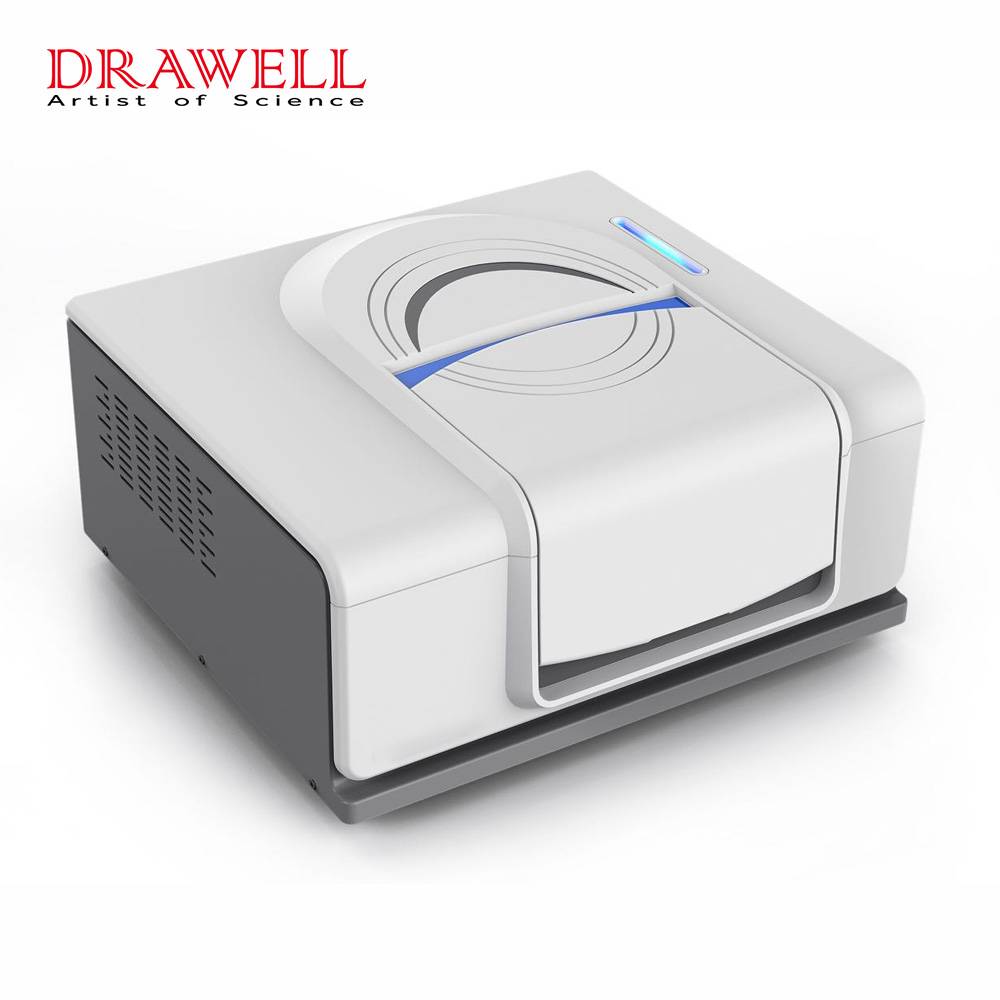

Related Products Recommendation

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.