A precise determination of the sulfur and carbon content is vital across all industries, from ensuring good quality of the steel alloys, to monitoring the environmental impact of emissions to identifying new materials. A carbon sulfur analyzer is an effective instrument to accomplish this goal. However, getting accurate results requires the proper preparation of the sample. This article will provide the fundamental tips and tricks to prepare samples for carbon sulfur analysis in order to get reliable and relevant results. In the end, knowing and using the proper methods of preparation for samples is an essential requirement for any lab that uses the carbon sulfur analyzer.

Importance of Sample Preparation in Carbon-Sulfur Analysis

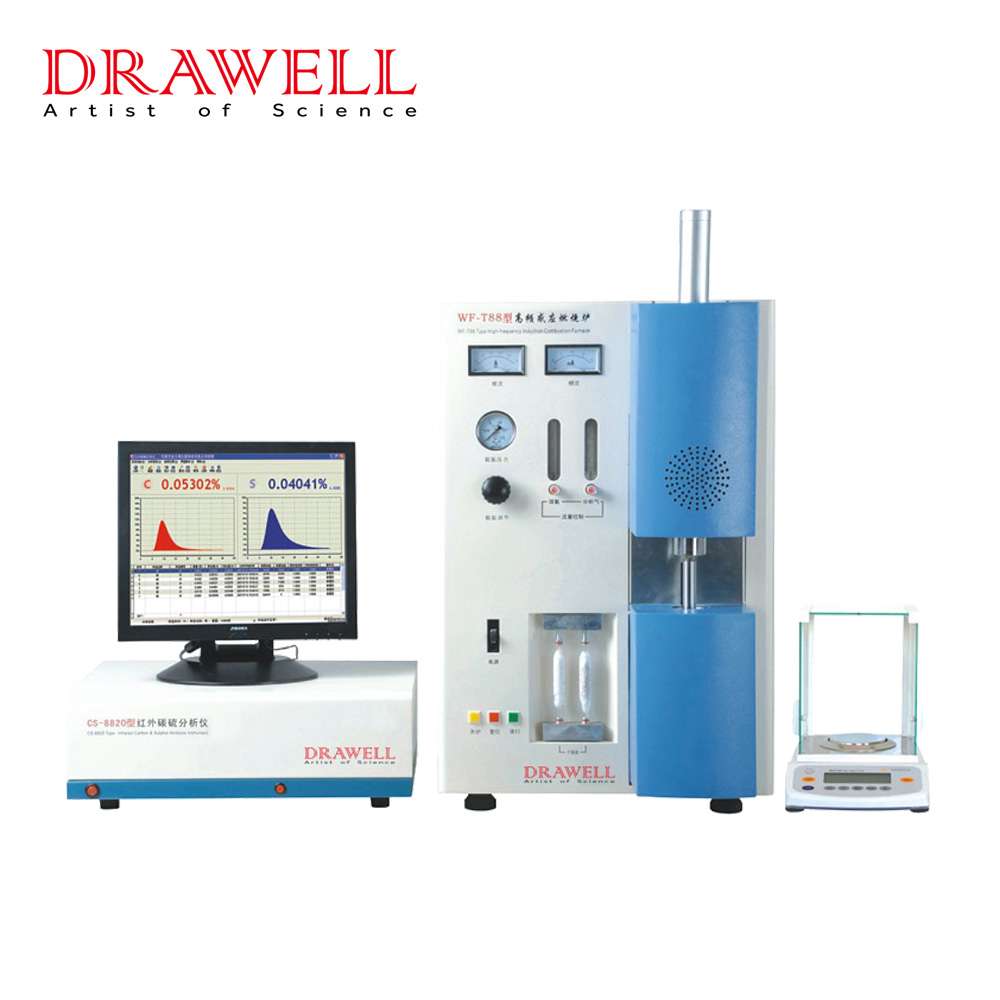

The fundamental principle behind all carbon sulfur analyzers is the high-temperature burning of the sample which is followed by the detection of the gases that evolved (typically CO2 SO2, CO2 or their similar forms). The analyzer then measures the amount of sulfur and carbon in the manner it is displayed. Incorrect sample preparation could lead to mistakes at the beginning of the process which can lead to inaccurate and misleading results, irrespective of the sophistication of the analyzer. For example, a heterogeneous sample could yield different results based on the aliquot that is being analyzed. In the same way, contamination arising from handling can cause false elevation of the carbon or sulfur levels. Thus, careful sample preparation isn’t just a preparatory step, but an integral element of the entire procedure, directly affecting the accuracy and reliability of the results for sulfur and carbon.

The Do’s of Preparing Samples

1. Choose the Right Equipment

The choice of the right instruments is crucial to get an accurate and appropriate test sample to analyze carbon-sulfur.

Use the right tools (grinders mortars, grinders, and cutting tools) to prepare sulfur and carbon sample preparation. Examples include:

| Tool Category | Examples | Application |

| Crushing/Grinding | Mortar and Pestle (Agate, Ceramic) | For brittle solids, minimizing contamination. |

| Grinding Mills (Ball Mill, Planetary Mill) | For materials that are harder, you can achieve tiny particle dimensions | |

| Cutting Devices (Abrasive Cut-off Wheel) | For separating hard or metallic samples. | |

| Cryogenic Mills | For those samples that are hard to mill at room temperatures, this helps to keep volatile elements. | |

| Handling | Spatulas (Stainless Steel, Ceramic, Glass) | To transfer powdered or small solid samples. |

| Scoops | To measure and transfer large quantities from powdered sample. | |

| Sieving | Sieves that come in different mesh sizes | To obtain a particular size range of particles and ensuring consistency in powdered samples. |

The most appropriate sampling methods for various types of samples (e.g. liquids, solids and powders). Here are a few suggestions:

| Sample Type | Technique | Description |

| Powders | Coning and Quartering | A method for reduction of a bulk sample to a more representative part by forming an elongated cone, flattening it and dividing it into quarters, then discarding the opposing quarters. Repeat as required. |

| Sample Divider (Riffle Sampler) | A device consisting of a sequence of chutes which continuously divides the particle into two distinct portions, allowing the diminution of the size of the sample while preserving the quality of the sample. | |

| Random Sampling of Multiple Locations | Small portions of various areas of the bulk powder in order to ensure that there is no segregation. Mix and homogenize these parts. | |

| Solids | Coring | Utilizing a cylindrical tool to take an appropriate core sample from the solid material. especially beneficial for non-homogeneous or large items. |

| Cutting and Sectioning at multiple locations | The idea is to take representative pieces or sections from various parts of the solid object in order to allow for possible variations in the material. | |

| Drilling (with cautions) | Extracting powder samples from certain depths or places within the structure of. It is important to ensure that the drill isn’t infected with sulfur-containing or carbon-containing substances or the lubricants. | |

| Liquids | Thorough Mixing (Stirring, Shaking) | Making sure that the liquid is homogeneous prior to taking an amount. The method is based on the viscosity as well as the volume of the liquid. |

| Sampling at Different Stages (if stratified) | If it is believed that the liquid that it is stratified samples must be taken from a variety of depths, and analyzed independently or in combination after ensuring homogenization. | |

| Use of Pipettes or Syringes | for accurately measuring and moving liquid samples to analyze. Be sure the pipettes and syringes are free of dirt and made from inert substances. |

The most important thing is to select the correct instrument and method of sampling minimizes any bias and makes sure that the sampled section accurately portrays bulk of the material.

2. Careful Handling and Storage

Making sure that the sample is not altered in composition throughout storage and handling is essential to ensure a precise determination of sulfur and carbon.

Guarantee Uniformity: Having homogeneous samples is often the first step to ensure a solid analysis.

What steps of homogenization or grinding are required? Based on the initial condition of your sample a variety of steps could be needed to ensure homogeneity. Samples of solids generally need grinding, or even milling to decrease the size of particles and improve homogeneity. liquid samples might require stirring or the process of sonication. Powders may require sieving to ensure a uniform proportion of size. The study focusing on coal analysis revealed that grinding the coal sample to less than 250 mm greatly improved the reliability of both sulfur and carbon measurements, while reducing average deviations by around 15% when compared with larger samples.

Control Contamination : Introducing foreign substances could directly affect the sulfur and carbon levels.

What are the common contaminants? The most common sources of contamination are dust in the environment and residues from sampling instruments (e.g. previously sampled samples or cleaning agents) as well as particles generated by grinding medium, or even fingerprints.

What can be done to ensure that contamination is minimized during sample preparation and analysis be reduced? The elimination of contamination requires strict adhering to safe lab practices. This means making use of clean, inert sample equipment (stainless steel, glass or glass) as well as operating in an hygienic, safe environment (e.g. or using an exhaust hood or clean bench) and wearing the suitable personal protection equipment (e.g. gloves) to stay clear of touching the sample directly. The equipment should be thoroughly cleaned between each sample using solvents that are suitable or cleaning methods that don’t leave sulfur or carbon-based residues.

Moisture Management Moisture could greatly impact the precision of sulfur and carbon analysis.

It is possible to ask what happens if the sample is dried and how will the moisture content of samples affect the results? Most of the time solid samples, they should be dried prior to analysis to ensure precise weight measurements, and to avoid interfering during combustion. Moisture is a major contributor to the sample’s weight but is not a source of sulfur or carbon, leading to an underestimation of actual percentages, if it is not properly accounted for. Additionally, the release of water vapor in the course of combustion may affect the determination of sulfur oxides and carbon. The method of drying (e.g. oven drying or desiccator) and the conditions (temperature and duration) should be selected carefully according to the thermal stability of the sample to ensure the safety the volatile compounds.

The implementation of rigorous procedures to ensure uniformity, preventing contamination and regulating moisture is essential to get solid data on sulfur and carbon.

3. Appropriate Sample Size and Form

The properties of the sample that are added to the analyzer directly impact the accuracy and efficiency of the process of combustion.

Carbon sulfur analyzer makers provide the recommended sample of weight for their equipment. Using a sample size that is not within this range may result in an insufficient burning (if the sample is too big) or lack of signal for precise determination (if smaller). Overloading the furnace for combustion can cause damage to the instrument. Always refer to the manual of your instrument to determine the appropriate sample weight.

The smaller size of particles as well as larger surfaces allow for greater efficiency and speedy combustion. This guarantees that all carbon and sulfur contained in the sample are converted into gaseous forms that are detectable. If the material is not completely combusted, it could result in underestimating the content of sulfur and carbon. So grinding solid samples into an extremely fine powder is usually required, particularly for Refractory materials. However, extremely fine powders may be difficult to work with because of electrostatic forces.

Conforming to guidelines for sample sizes and maintaining an appropriate physical structure is essential to ensure full and effective combustion inside the analyzer.

Carbon sulfur analyzers manufacturers offer detailed instructions and guidelines specific to their equipment. The guidelines cover many aspects, such as the proper preparation of the sample, optimal weight, appropriate sample matrices and the possibility of interferences. In the absence of these guidelines, you could cause suboptimal performance as well as inaccurate results and even harm on the device. Always consult the manual of your instrument for specific directions on preparation of samples and consult the application specialists of the manufacturer in case you are unsure or are working with unorthodox samples.

The Don’ts of Preparing Samples

Making sure you avoid common mistakes during the preparation of samples is just as important as ensuring that you follow the proper methods.

| Common Mistake | Potential Consequence | Recommended Solution |

| Neglecting Representative Sampling | The results are not skewed and don’t represent the full material. | Use the appropriate sampling methods depending on the type of material. Make several samples and homogenize when needed. |

| Introducing Contamination | Falsely elevated carbon or sulfur readings. | Clean containers and tools. Wear gloves. Be sure to work in a clean and safe environment. Clean the equipment regularly between samples. |

| Using Incorrect Sample Size | Incomplete combustion (too big) (too large) or a weak signal (too too small). | Follow strictly the recommended weight range for the analyzer. |

| Inadequate Grinding/Homogenization | Incomplete combustion, inconsistent results. | Make sure that the samples are ground to the correct size to ensure full combustion. Make sure that the powdered samples are thoroughly mixed. |

| Improper or No Drying | Inaccurate weight measurements and potential burning issues. | Dry the samples by using a method that is appropriate and under conditions that are appropriate for the matrix, to ensure that there is no loss the volatile analysis. |

| Ignoring Blank Runs | Inaccurate background corrections can lead to systematic mistakes. | Always test samples with blanks to check background levels of sulfur and carbon. |

| Using Contaminated Standards | Incorrect calibration results in incorrect results for samples. | Take care to handle your calibration standard with the same respect that you would handle samples. Make sure they are properly stored and do not exceed the expiration date. |

| Deviating from the manufacturer’s instructions | Suboptimal performance, inaccurate results, instrument damage. | Always read and follow the instructions provided by carbon sulfur analyzer manufacturer. |

| Using Reactive Grinding Media | Injection of sulfur or carbon in the specimen. | Make use of grinding media made from inert substances (e.g. or agate ceramic) that won’t contaminate the sample with elements of the sample. |

| Storing Samples Improperly | Degradation, oxidation or loss of volatile compounds. | Keep samples in containers that are suitable in conditions that will not allow for the change in their carbon and sulfur levels (e.g. dry, cool, an inert environment). |

If they are aware of these common traps and following the suggested solutions analysts can greatly increase the accuracy and accuracy of their analysis of sulfur and carbon.

A precise and reliable carbon sulfur analysis is dependent on the careful preparation of samples. By following these “do’s” of proper sampling handling, homogenization and controlling moisture, and being mindful of the most common “don’ts” that can introduce mistakes, laboratories can increase the precision and accuracy of their findings. The advice offered by carbon sulfur analyzer makers is a vital resource for this process. They not only design and construct the instruments however, they also provide essential information and assistance to make sure the sample is prepared properly. Contact them whenever you require.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.