The melting point instrument is popularly used in the world. Today, this article will focus on the functional characteristics of the oil melting point apparatus and the determination of the melting point of oil (refined tallow of animal fat) by the oil melting point apparatus.

Functional Characteristics of Oil Melting Point Apparatus

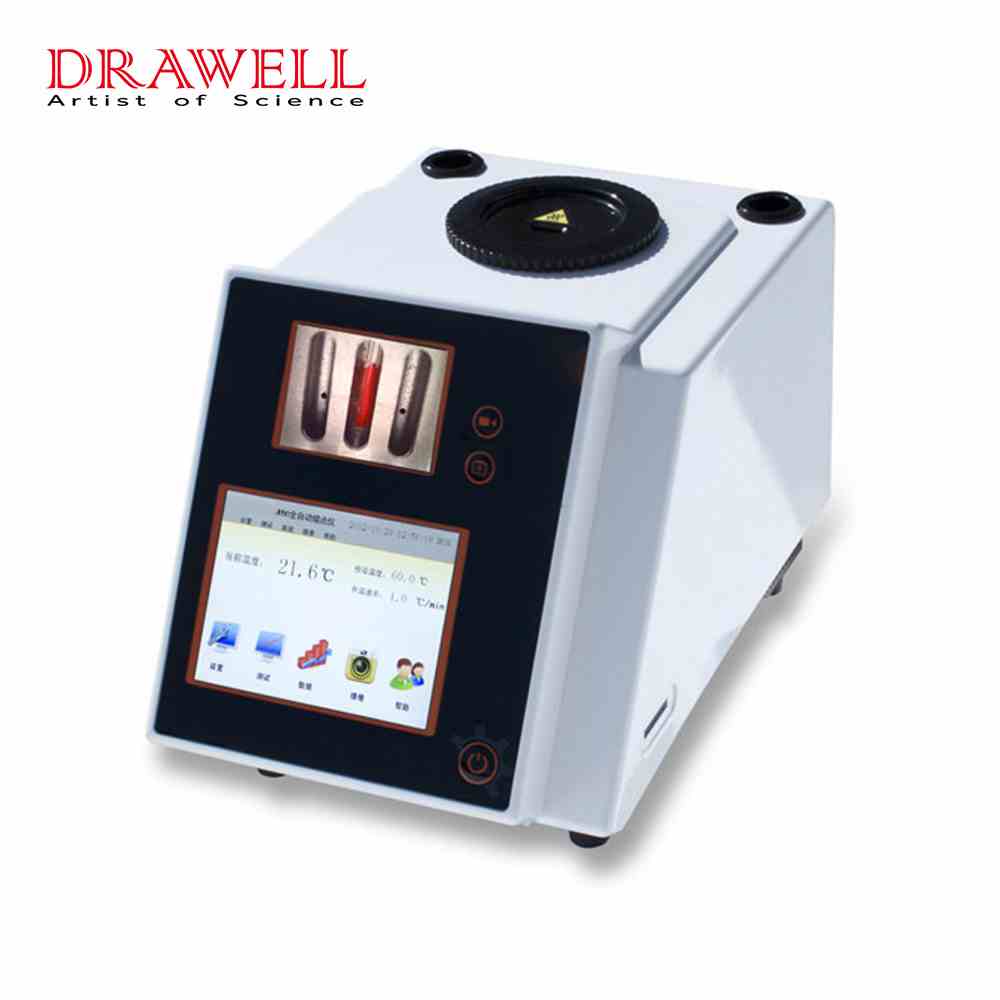

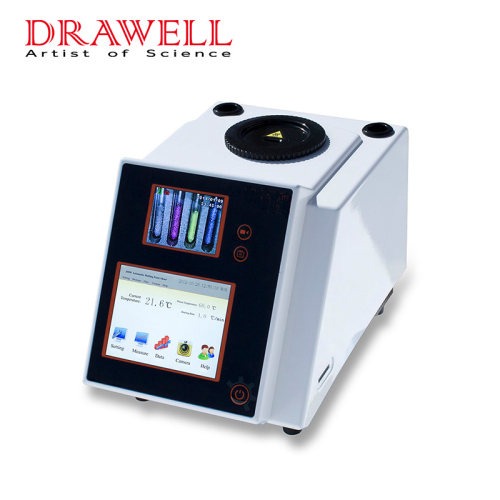

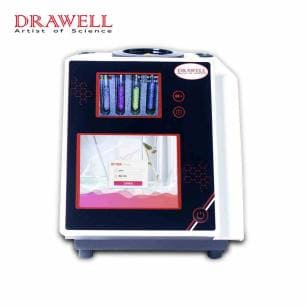

The oil melting point apparatus can quickly measure the melting point of various oils. Three samples can be determined simultaneously. The entire experimentation process is digitalized and sent to the computer via the digital optical sensor. The intelligent software can automatically judge the oil melting point, eliminate the subjective error of artificial judgment of the melting point, and reduce the labor intensity of the experimental personnel. JHY90 grease melting point apparatus is equipped with a heating system, which can ensure a stable heating rate. The platinum temperature sensor has fast response speed and high temperature and has incomparable advantages over traditional mercury thermometers.

Functional Characteristics of Oil Melting Point Apparatus

1. 8-inch high-definition super capacitive touch screen

2. 720P high-definition camera, 8 times optical magnification, sample detail magnification, sample detail changes are visible;

3. Linear heating rate 0.10 ℃ – 20.00 ℃, stepless and adjustable.

4. It can be connected with an external water-circulating device so that the sample test is not limited by the temperature of the environmental chamber.

5. It can store customers’ experimental methods, historical measurement data, videos, and maps.

6. Unique video coding technology, which can store about 10,000 minutes of video data.

7. It can export experimental reports and data in PDF, Excel, and other formats.

8. With a multi-point calibration function, the instrument can be calibrated through multiple temperature points.

9. With the data retrieval function, it is convenient to look up past data.

10. USB printer, thermal printer, or USB flash disk can be connected to export the test report, or a wireless printer can be connected through wireless WiFi.

11. Say goodbye to the traditional manual testing method, and achieve full automatic testing, which can save a lot of manpower, eliminate the need for personnel to observe the testing process for a long time, and greatly improve the working efficiency of the laboratory.

Determination of Melting Point of Oil (Refined Tallow Of Animal Fat) by Oil Melting Point Apparatus

First, the experiment principle

The temperature at which a substance transforms from a solid to a liquid is referred to as its melting point. In the field of organic chemistry, melting point measurement is the basis for identifying the nature of a substance and is one of the important methods for purity measurement. In the cosmetics and food industries, measuring the sliding melting point of a sample plays a very important role in the quality control of products. For example, the determination of sliding melting point can be used to control the quality of cocoa butter or palm oil in edible fat samples. Drawell Automatic Grease Melting Point Tester can quickly and accurately measure the sliding melting point of various oils. Three samples can be determined simultaneously. The entire experiment procedure is digitalized and sent to the computer via the digital optical sensor. The intelligent software can automatically judge the oil melting point, eliminate the subjective error of artificial judgment of the melting point, and reduce the labor intensity of the experimental personnel. The instrument is equipped with a heating system to ensure a stable heating rate. The platinum temperature sensor has fast response speed and high accuracy and uses a mercury thermometer more than traditional methods.

Second, experimental equipment and preparation:

Experimental apparatus: JHY90 full-automatic grease melting point instrument, large capillary sleeve.

Preparation: sample (butter sample submitted by the customer) double opening capillary tube.

Third, experimental steps:

1) Sample pretreatment: preheat the instrument, inject about 40mm high water column into the large capillary tube, put it into the instrument furnace, and load about 6 mm~8 mm oil column sample into the double open capillary tube.

2) Startup test of melting point instrument: open the melting point instrument to set parameters.

3) Test results.