Fiber analysis stands as a cornerstone in the realms of agricultural and food sciences, providing crucial insights into the nutritional composition of various products. Among the diverse methodologies available, the Crude Fiber Analyzer (CFA) emerges as a transformative innovation, promising enhanced accuracy and efficiency in fiber analysis. This article delves into the significance of crude fiber analysis, the workings of the Crude Fiber Analyzer, its advantages over traditional methods, applications across agricultural and food industries, and concludes with reflections on its profound impact.

Why Use Crude Fiber Analysis?

Understanding the fiber content within agricultural products and food items holds paramount importance for various stakeholders, including farmers, nutritionists, and food manufacturers. Fiber analysis allows for precise determination of dietary fiber content, aiding in nutritional labeling, animal feed formulation, and quality assessment of processed foods. Fiber-rich diets have been associated with numerous health benefits, including improved digestive health, weight management, and reduced risk of chronic diseases such as diabetes and heart disease. Therefore, accurate fiber analysis is indispensable for promoting public health and ensuring consumer transparency.

Advantages of Using the Crude Fiber Analyzer over Traditional Methods

Using a crude fiber analyzer offers several advantages over traditional methods for determining fiber content in food and feed samples:

- Standardization: Crude fiber analysis follows standardized procedures outlined by organizations such as the Association of Official Analytical Chemists (AOAC) or the American Association of Cereal Chemists (AACC). These standardized methods ensure consistency and reproducibility of results across different laboratories and analysts.

- Simplicity: Crude fiber analysis is a relatively simple and straightforward procedure compared to other methods for fiber determination. It involves a series of standardized steps, including sample preparation, digestion, filtration, and drying, which can be easily performed with basic laboratory equipment.

- Cost-Effectiveness: Crude fiber analysis is a cost-effective method for determining fiber content in food and feed samples. The equipment required for analysis is relatively inexpensive compared to more sophisticated analytical techniques, making it accessible to laboratories with limited resources.

- Wide Applicability: Crude fiber analysis can be applied to a wide range of food and feed samples, including grains, cereals, fruits, vegetables, and animal feeds. It is suitable for both soluble and insoluble fiber fractions, providing a comprehensive estimate of total dietary fiber content.

- Regulatory Acceptance: Crude fiber analysis is a recognized method for fiber determination by regulatory agencies and industry standards organizations. Results obtained using crude fiber analysis are widely accepted for compliance with labeling requirements and quality control specifications.

- Historical Perspective: Crude fiber analysis has been used for many years in the food and feed industries and has a long history of application. As a result, there is a wealth of historical data and reference values available for comparison and interpretation of results.

- Reproducibility: When performed according to standardized procedures, crude fiber analysis typically yields reproducible results with low variability between replicate samples and analyses. This reliability is essential for quality assurance and regulatory compliance purposes.

While crude fiber analysis has several advantages, it is important to recognize its limitations, including the inability to detect certain types of dietary fiber and the potential for overestimation or underestimation of fiber content in certain samples. As such, it is often used in conjunction with other analytical methods to provide a more comprehensive assessment of fiber composition in food and feed samples.

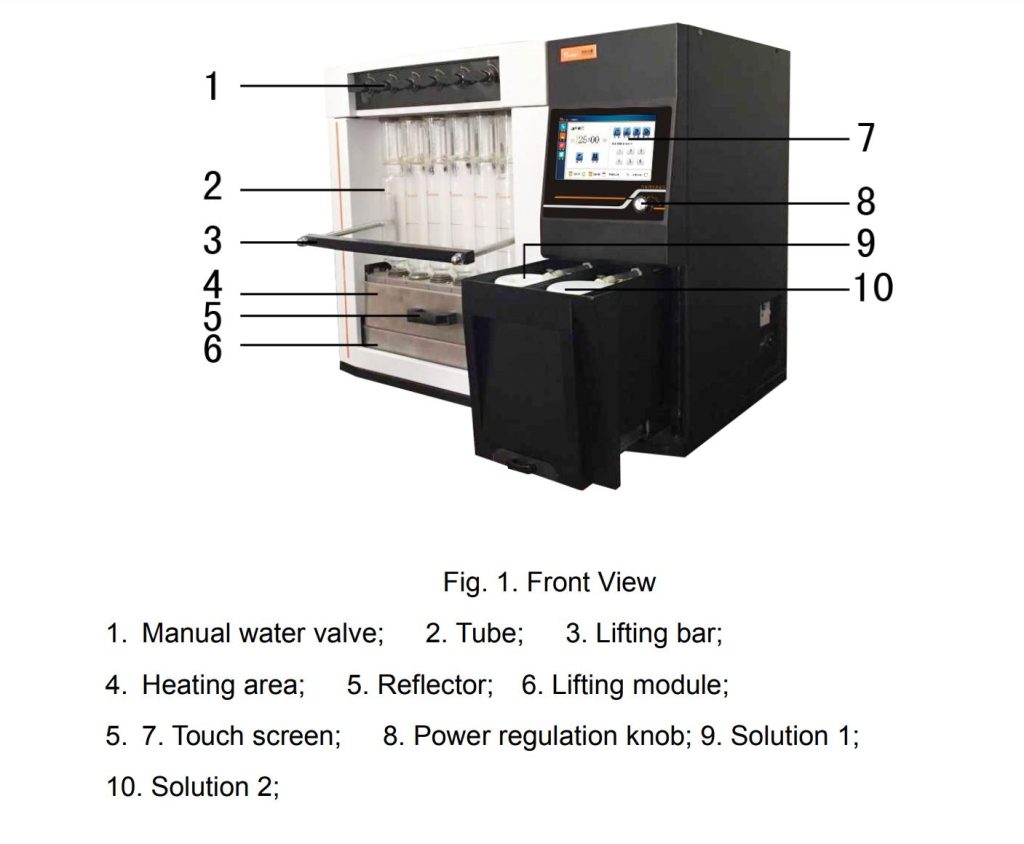

How the Crude Fiber Analyzer Works?

A crude fiber analyzer is a laboratory instrument used to determine the crude fiber content of food and feed samples. Here’s a basic overview of how a crude fiber analyzer works:

- Sample Preparation: The first step involves preparing the sample for analysis. This may include grinding the sample to a uniform particle size and drying it to remove moisture.

- Digestion: The sample is subjected to a two-step digestion process to remove the soluble components and isolate the insoluble fiber fraction. In the first step, the sample is treated with a dilute acid solution (usually sulfuric acid) to remove protein, sugars, and other soluble components. The mixture is then heated under controlled conditions to break down the cell wall structures and release the insoluble fiber.

- Filtration: After digestion, the sample is filtered to separate the insoluble fiber residue from the liquid phase containing the soluble components and digested material. The residue is washed to remove any remaining soluble material.

- Drying and Weighing: The filtered residue, which consists primarily of cellulose, hemicellulose, and lignin, is dried to remove any remaining moisture. Once dry, the residue is weighed to determine the mass of crude fiber in the sample.

- Calculation: The crude fiber content is calculated based on the weight of the dried residue and expressed as a percentage of the original sample weight.

- Reporting: The results of the analysis are reported along with any relevant sample information, such as sample ID, preparation method, and analysis conditions.

It’s important to note that crude fiber analysis provides an estimate of the total fiber content in a sample but may not capture all types of dietary fiber, such as resistant starches and some non-cellulosic polysaccharides. Additionally, the method has limitations and may not be suitable for certain types of samples or complex matrices.

Despite its drawbacks, crude fiber analysis remains a widely used method for determining fiber content in food and feed samples due to its simplicity, reproducibility, and established protocols. Advances in analytical techniques have led to the development of more sophisticated methods for fiber analysis, but crude fiber analysis continues to be a standard method in many laboratories and regulatory agencies.

Applications of Crude Fiber Analyzer in Agriculture and Food Industry

A Crude Fiber Analyzer is a vital instrument in the agriculture and food industry, used to determine the crude fiber content in various samples. Crude fiber refers to the indigestible components of plant material, primarily consisting of cellulose, hemicellulose, and lignin.

Applications of Crude Fiber Analyzer in Agriculture:

- Evaluating feed quality: Crude fiber content is a crucial factor in determining the nutritional value of animal feed. It influences digestive health, nutrient absorption, and animal performance. By analyzing the crude fiber content, farmers and feed producers can formulate balanced diets for their livestock, ensuring proper growth and development.

- Developing new crop varieties: Plant breeders utilize crude fiber analysis to assess the fiber content of new crop varieties during development. This information helps them select varieties with desirable fiber characteristics for specific purposes, such as high-fiber animal feed or low-fiber crops for human consumption.

- Monitoring soil health: Crude fiber content in soil organic matter plays a role in soil fertility and structure. By analyzing the crude fiber content in soil samples, researchers and agricultural professionals can gain insights into soil health and implement appropriate management practices to improve it.

Applications of Crude Fiber Analyzer in Food Industry:

- Quality control: Food manufacturers employ crude fiber analysis to ensure consistent quality and meet labeling requirements for fiber content in their products. This is particularly important for products marketed as high-fiber or low-fiber, such as cereals, bread, and snacks.

- Product development: Food developers use crude fiber analysis to formulate new food products with specific fiber content. This caters to the growing consumer demand for high-fiber food options associated with various health benefits.

- Regulatory compliance: Food regulations in many countries mandate the declaration of fiber content on food labels. Crude fiber analysis helps food companies comply with these regulations and avoid potential legal and reputational issues.

In conclusion, Crude Fiber Analyzers play a significant role in the agriculture and food industry by enabling the evaluation of feed quality, development of new crop varieties, monitoring of soil health, ensuring food quality control, product development, and regulatory compliance.

Conclusion

In conclusion, the Crude Fiber Analyzer emerges as a revolutionary tool reshaping the landscape of agricultural and food sciences. By providing rapid, accurate, and reproducible fiber analysis, the CFA empowers researchers, farmers, and food manufacturers to make informed decisions and optimize production processes. As technological advancements continue to drive innovation in fiber analysis, the Crude Fiber Analyzer stands as a testament to progress, ushering in a new era of precision and efficiency in dietary fiber analysis. As we look to the future, the continued refinement and integration of the CFA promise to further elevate standards in agricultural and food sciences, ultimately benefiting public health and global food security.