Magnetic hot plate stirrers are essential tools for laboratories, combining mixing and heating into one device. Their versatility allows them to be employed in a variety of industrial and scientific applications. But, a frequent question is the following: Are the magnetic stirrers compatible for all types of liquids? The answer is simple: although magnetic hot plates provide significant advantages in many applications but their compatibility is restricted by specific liquid characteristics. We will explore how magnetic stirrers work for different types of liquid and offer practical guidelines for their optimal usage.

What is a Magnetic Hot Plate Stirrer?

An magnetic hot plate stirrer is an lab device that is able to combine the functions in a magnet stirrer with hot plate. It is typically comprised of an unheated, flat surface, and an inner rotating magnetic. A stirring bar with a magnetic magnet is encased in the liquid that needs to be stirred and placed in a glass container and placed on the hot plate’s surface. The magnet that rotates inside the device generates magnetic fields that interact with the stir bar making it spin, and mixing the liquid. The heating element integrated permits simultaneously heating the liquid with temperature control mechanisms that ensure precision.

Stirrers for hot plates magnetic provide many advantages that contribute to their widespread use in labs:

- Contactless Stirring: The stirring mechanism is based on magnetic fields that are not directly in connection between any moving part of the Stirrer with the liquid. This means there is no risk of contamination from stirrers and paddles. This can be essential in sterile or sensitive research.

- Sealed Systems: This capability to stir outside of the container permits closed systems. This is vital when working with hazardous, volatile or air-sensitive materials.

- Usability and Cleaning: The magnetic stir bars are easy to clean and sterilize and their flat surfaces are easy to clean. This drastically reduces maintenance as compared to mechanical stirrers having many components.

- Simultaneous Heating and Stirring: The combined mixing and heating functions speed up experiments, allowing homogeneity and controlled temperature to be achieved simultaneously.

These advantages are what make magnets that stir with hot plates an essential instrument for a variety of laboratory applications, ranging from simple preparation of solutions to more complex chemical syntheses.

Compatible with Different Liquids

Standard magnetic stirrers can be best suited for moderate to low viscosity liquids. In these liquids the magnetic interaction between internal magnetics and the stirring bar can be enough to produce and maintain the same stirring pattern and facilitates a thorough mixing. Examples include dilute aqueous solutions, as well as several common organic solvents.

When viscosity rises but the resistance to the bar’s movement also increases. In the end, a point has been reached at which the torque created by a typical magnetic stirrer is not enough to overcome the resistance effectively. This may manifest in a variety of ways such as: the bar can move very slowly, in a erratic manner or become completely disconnected with the field of magnetic force (“spin-out”). In the end, mixing is insufficient or ceases completely. Liquids like viscous oils, concentrated syrups or medium to low concentration polymer solutions usually are in this category and have limitations in compatibility with magnetic stirrers.

For high viscosity liquids, specially designed magnetic stirrers that have high torque are available. They are designed with stronger magnets as well as more powerful motors that can generate the required force needed to stir more resistant liquids. They also expand the compatibility of liquids, high-torque stirrers also have limitations. Extremely viscous liquids like polymer melts or extremely concentrated gels, frequently exceed the capabilities of even most durable magnetic stirring systems and require other mixing techniques such as over-the-top mechanical stirrers.

The table below outlines how magnetic stirrers work that are based on viscosity

| Viscosity Range | Examples | Standard Magnetic Stirrer Compatibility | High-Torque Magnetic Stirrer Compatibility | Alternative Mixing Methods |

| The low (1-10 mPa*s) | Water, ethanol, dilute solutions | Excellent | Excellent | A magnetic stir is generally sufficient. |

| Medium (10-1,000 mPa*s) | Vegetable oil, Glycerol (dilute) and a few polymers | Often Effective | Effective | A magnetic stir is usually enough. |

| Very high (1,000-10,000 mPa*s) | Honey, concentrated syrups certain resins | Limited Effectiveness | Good | Take into consideration a high-torque, overhead or overhead stirrer. |

| Highly high (>10,000 mPa*s) | The thick polymer solutions, gels Some adhesives | Ineffective | Limited Effectiveness | Overhead stirrer, mixer with mechanical. |

It’s important to keep in mind that even though these types of liquids tend to be compatible their specific concentration as well as the temperature and speed can affect the effectiveness of mixing. For liquids that aren’t in this range, or that have unique characteristics need to be considered with care and alternate methods of stirring are needed.

Factors Affecting Compatibility

The compatibility the magnetic stirrer to specific liquids is determined by the following variables:

| Factor | Reason | Tips |

| Viscosity | Determines the level of resistance to stirring. Higher viscosity liquids cause more resistance. | Utilize a strong motor and slower speed settings and bigger stir bars in viscous liquids. |

| Volume | Larger volumes require greater energy to ensure an even mixing. | The capacity of the stirrer should be matched to the volume of liquid so that you don’t overload the device. |

| Stir Bar Type/Size | Influences how motion is transferred to liquid. | Utilize larger or pivot-ring stirring bars to stir viscous liquids. Use smaller stir bars for less viscous ones. |

| Material Compatibility | Certain liquids may corrode or damage the device or stir bar components. | Make sure you use PTFE-coated stir bar and make sure that the equipment is made from suitable materials. |

| Temperature Requirements | The effects of heating can alter the liquid’s properties and alter the stir bar’s performance. | Be sure to monitor temperatures carefully and stay within the ranges recommended for devices and liquids. |

| Container Shape/Material | Influences the formation of a vortex, and also the device’s stability. | Use flat-bottom containers made from glass or plastic that is resistant to make effective stirring. |

These aspects must be thoroughly assessed when determining the suitability of the magnetic stirrer with hot plates for a particular application.

Best Practices for Using Magnetic Hot Plate Stirrers

To increase the efficiency and long-term use that your magnet hot plate stirring device has, and to ensure that it is mixing properly for different liquids, you should consider the following guidelines:

1. Choosing the Appropriate Equipment:

Tips for choosing the right stirrer and bar to suit the type of liquid you are using.

- Stirrer Torque: For low to medium viscosity liquids using a regular magnetic stirrer is usually adequate. However, if you are you are working with viscous liquids (e.g. oil, certain oils, polymer solutions with a medium concentration) think about a high-torque magnetic stirrer. They are constructed with stronger motors and magnets to withstand the higher resistance. Manufacturers typically indicate the maximum viscosity or capacity of water of their units.

- Stir Bar Dimensions and shape: The dimension of the bar’s stir should be suitable for the size as well as the shape and size of your container. A stir bar that’s too small may not produce enough turbulence, whereas one that is too big may become unstable and end up damaging the container. The most common shapes are cylindrical triangular, oval, and all of which have distinct mixing properties. For example triangular stir bars is more efficient at moving particles that have settled in suspensions than one that is cylindrical.

- Stir Bar Materials: Make sure the material of the stir bar can be chemically compatible with liquid that is being stirred. Stir bars coated with PTFE are popular because of their chemical inertness. glass coated stir bars have better resistance to chemical corrosive substances however they are also more fragile.

2. Testing and Adjustments

Mixing at the optimal level often requires some trial and error like fine-tuning the speed of stirring.

- Gradual Speed Acceleration: Begin with a slow stirring speed, then gradually increase the speed until a smooth vortex develops within the liquid. Avoid speeds that are too high, as they could result in splashing, or even the stirring bar losing its magneto-coupling (“spin-out”).

- Vortex Observation: The form and durability of the vortex may reveal the effectiveness of mixing. A vortex that is well-formed and extends near at the top of the bottle usually is a sign of good mixing.

- Viscosity Adjustment (if possible): in some situations, it may be possible to adjust the viscosity of the liquid either by altering the temperature (if heating isn’t detrimental to the research) and/or by adding solvent compatible to the experiment.

- Two Stir Bars: to handle large quantities or more difficult mixing tasks, mixing two stir bars that are smaller can improve homogeneity.

3. Looking for Accessories or Alternative Stirring Methods

When magnetic stirring is not enough, various alternatives or accessories are available:

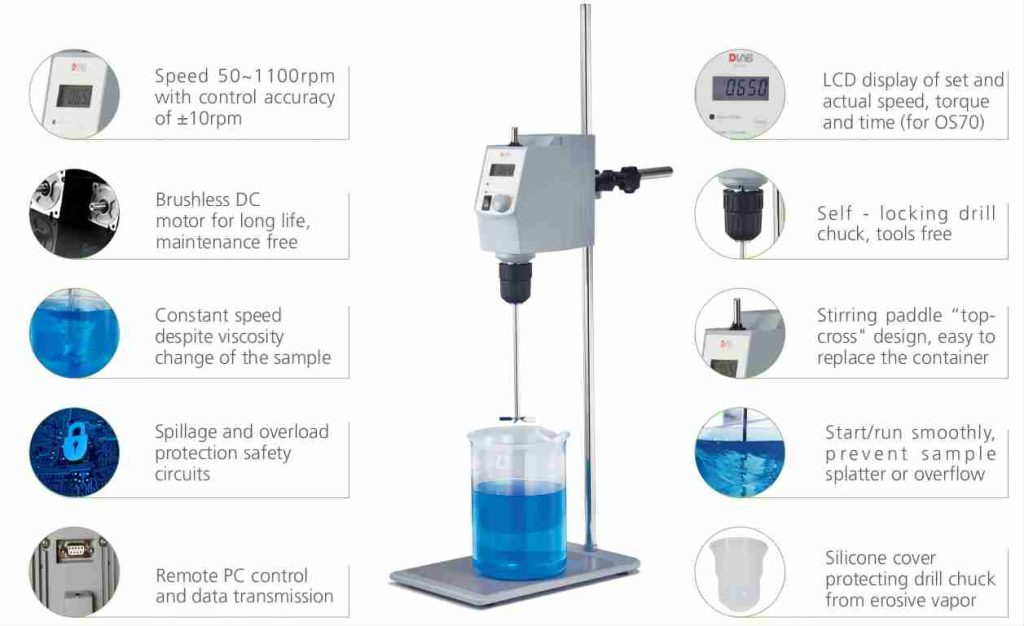

- Overhead Stirrers: are ideal for extremely viscous liquids, such as many polymers and resins overhead stirrers equipped with mechanical impellers are typically the most preferred option. They provide a higher torque and are able to handle more viscous substances. Different impeller types (e.g. anchor, paddle, helix) can be used to optimize mixing to suit specific viscosity ranges as well as container geometries. For instance an anchor impeller can be effective in scratching away the side of the vessel to prevent the buildup of material by using viscous resins.

- Vortex Mixers: for rapid mixing of smaller volumes Vortex mixers are extremely efficient. They create a swirling motion that rapidly homogenizes liquid.

- Shakers and Rockers Shakers: and Rockers devices are ideal for mixing emulsions, suspensions or other liquids when gentle but steady movement is needed. They are particularly useful for biological samples or other applications in which shear forces have to be reduced.

- Ultrasonic Stirrers: In a few special uses, the ultrasonic stirrers may be utilized to improve mixing, specifically to disperse nanoparticles or create fine Emulsions.

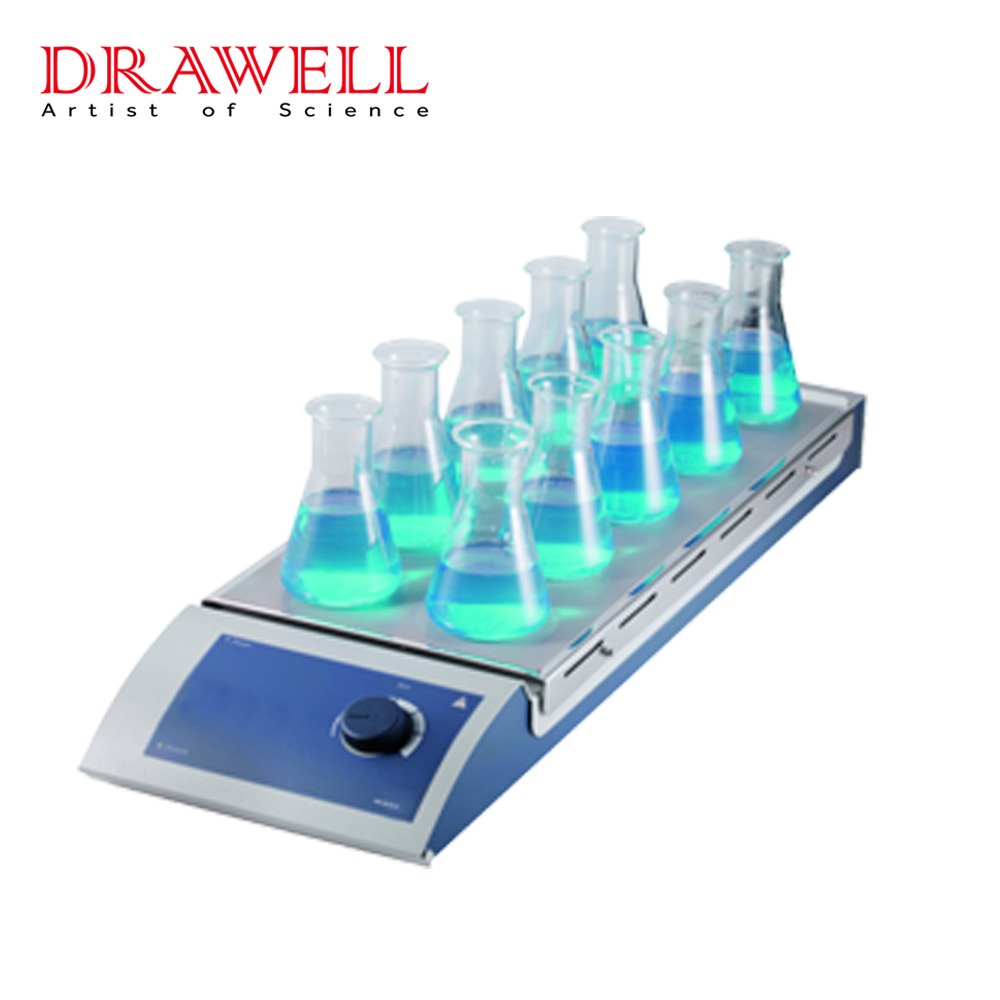

- Multi-Position Stirrers: For microscale or high-throughput applications, multi-position magnet stirrers can be used to facilitate simultaneous stirring of many samples, thus increasing efficiency. They are typically used to stir microplates or vials.

4. Safety Precautions

Utilizing magnetic hot plate stirrers could pose a risk which require care:

| Potential Hazard | Ways to Avoid |

| Overheating of Liquid or Device | Be sure to monitor temperature and utilize built-in safety features, such as auto-shutoff and temperature limits. |

| Chemical Spills or Reactions | Always use containers that are compatible and make sure that the liquids remain stable when stirred and heating conditions. |

| Stir Bar Dislodgment | Begin at a slow speed, then increase it gradually to stop your stir bar falling out of its position. |

| Device Instability or Tipping | Make sure you are operating on a stable, smooth surface. Avoid using too much volume of liquid. |

| Corrosion or Material Damage | Make use of PTFE-coated stir bar and ensure that all materials that are in contact with the liquid have chemical compatibility. |

| Burns or contact to Hot Surfaces | Wear the appropriate PPE, such as gloves with heat resistance and let the hot plate cool prior to handling. |

| Electrical Hazards | Make sure the device is connected to a neutral outlet. ensure that liquids are kept away from electronic components. |

| Contamination or Cross-Reactivity | Cleanse the device and thoroughly stir the bars during use, especially when working with different chemicals. |

Regular maintenance and the adherence to these guidelines will greatly improve safety and extend the lifespan that your magnet hot plate.

In summary, although magnetic hot plate stirrers are indisputably versatile and are essential in modern labs However, their compatibility isn’t completely. They are particularly effective in low- to medium-viscosity liquids, allowing for effective mixing as well as accurate temperature monitoring. However, there are challenges with extremely viscous liquids, thick suspensions, as well as chemicals that are chemically active. Understanding the variables that impact compatibility, like density and viscosity, and adhering to the best practices in the selection of stirrers and stir bars as well as speed adjustments and safety is essential for success in operation. If magnetic stirring is reaching its limits, experimenting with alternatives to stirring techniques like overhead stirrers become necessary in particular for projects involving polymers and resins, or for high-throughput screening. By taking into consideration the properties of the liquid, and deciding on the right equipment and methods researchers can profitably make use of the advantages of magnets and hot plates to meet many different research requirements.

Related Products Recommendation

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.