Laboratory freezers are indispensable in a variety of scientific fields, from medical research to pharmaceutical development. They ensure the integrity of samples and materials, often under strict temperature conditions. However, selecting the right laboratory freezer involves more than focusing on performance specifications. Balancing cost and energy efficiency is a critical consideration for labs aiming to manage budgets responsibly while adhering to sustainability goals.

Here we explore the multifaceted costs of laboratory freezers, the importance of energy efficiency, and strategies to achieve a balance that meets both financial and environmental objectives.

The True Cost of Laboratory Freezers: Beyond the Purchase Price

The sticker price of a laboratory freezer is often the most immediate cost considered during procurement. However, to gain a comprehensive understanding of the financial implications, it’s crucial to look beyond this initial outlay and consider the long-term expenses associated with ownership and operation.

Initial Acquisition Cost: This encompasses the base price of the freezer unit itself. This cost can vary significantly depending on factors such as the freezer’s capacity (measured in cubic feet or liters), temperature range (e.g., -20°C, -40°C, -80°C or ultra-low temperature (ULT)), features (e.g., alarm systems, data logging), brand reputation, and specific design (e.g., upright, chest). For instance, a basic -20°C freezer for general storage will have a lower initial cost compared to a high-capacity ULT freezer equipped with advanced monitoring capabilities. Specialized features like vacuum insulation panels or hydrocarbon refrigerants, often found in more energy-efficient models, can also influence the initial price.

Operational Costs: These are the recurring expenses incurred throughout the freezer’s lifespan and often dwarf the initial purchase price. The most significant operational cost is typically energy consumption. Laboratory freezers, especially ULT units that maintain extremely low temperatures, are energy-intensive appliances operating continuously, 24 hours a day, 365 days a year. A single ULT freezer can consume as much energy as a small household annually, leading to substantial electricity bills. For example, older, less efficient ULT freezers can draw anywhere from 10 to 20 kWh per day, translating to hundreds or even thousands of dollars in electricity costs per year, depending on local energy rates.

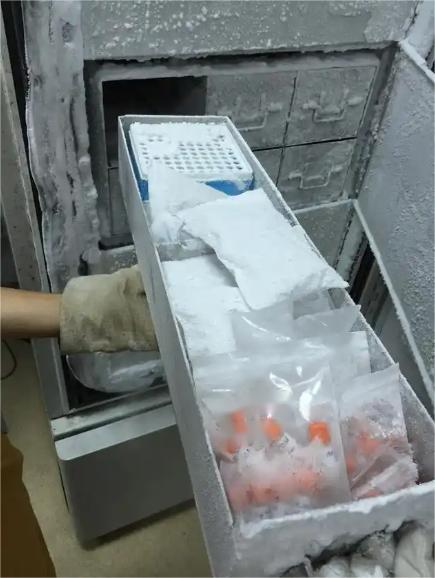

Samples in ULT freezer

Beyond energy, maintenance and servicing represent another significant operational cost. Regular maintenance, such as defrosting (for non-frost-free models), cleaning filters, and checking door seals, is crucial for optimal performance and longevity. Unexpected repairs, such as compressor failures or control system malfunctions, can be costly. Furthermore, the cost of sample loss due to freezer malfunction, although not a direct operational expense in the traditional sense, represents a potentially devastating financial and scientific setback. Investing in reliable freezers with robust alarm systems and considering backup power solutions can mitigate this risk. Finally, disposal costs, including any fees associated with the proper handling and recycling of refrigerants and electronic components, should also be factored into the total cost of ownership.

In conclusion, while the initial purchase price is a tangible upfront cost, a comprehensive financial assessment of laboratory freezers must account for the substantial and ongoing operational expenses, particularly energy consumption and maintenance, as well as the potential costs associated with sample loss and disposal.

Understanding Energy Efficiency in Laboratory Freezers

In an era of increasing environmental awareness and escalating energy costs, energy efficiency has become a paramount consideration in laboratory freezer selection. Choosing energy-efficient models not only reduces operational expenses but also contributes significantly to a laboratory’s sustainability efforts.

Energy-efficient laboratory freezers minimize their electricity consumption, directly translating to a lower carbon footprint. By reducing the demand for power generated from fossil fuels, these freezers help conserve natural resources and mitigate greenhouse gas emissions, contributing to broader environmental sustainability goals. Furthermore, reduced energy consumption can lessen the strain on building infrastructure and potentially lower the overall energy demand of a laboratory facility. This aligns with institutional and global initiatives aimed at reducing energy consumption and promoting environmentally responsible practices within the scientific community.

Key Energy-Saving Technologies and Features

Manufacturers are continually innovating to improve the energy efficiency of laboratory freezers. Several key technologies and features contribute to significant energy savings.

- Advanced insulation materials, such as vacuum insulation panels (VIPs), offer superior thermal resistance compared to traditional foam insulation, reducing heat ingress and the workload on the compressor.

- Energy-efficient compressors, often employing variable speed or natural refrigerants (e.g., hydrocarbons like R290), optimize cooling performance while minimizing energy draw.

- Improved door seal designs and reduced ice buildup minimize cold air leakage, further enhancing efficiency.

- Some models also incorporate smart controls that optimize cooling cycles based on usage patterns and ambient conditions. For instance, some ULT freezers offer a “eco” mode that allows for slightly higher operating temperatures when sample sensitivity permits, resulting in substantial energy savings.

Impact of Usage and Management Practices on Energy Consumption

Even the most energy-efficient freezer can consume excessive energy if not used and managed properly. Frequent and prolonged door openings allow significant amounts of warm, humid air to enter, forcing the compressor to work harder to restore the internal temperature. Implementing strict protocols for sample retrieval and ensuring doors are closed promptly are crucial.

Proper loading and organization within the freezer allow for efficient air circulation, preventing hotspots and ensuring uniform cooling, which can reduce the strain on the cooling system. Overpacking, on the other hand, can impede airflow and increase energy consumption. Regular defrosting of non-frost-free models prevents ice buildup, which acts as an insulator and reduces cooling efficiency. Finally, ensuring proper ventilation around the freezer allows for efficient heat dissipation from the compressor, improving its performance and lifespan.

In conclusion, energy efficiency in laboratory freezers is driven by innovative technologies and thoughtful design, leading to significant reductions in energy consumption and environmental impact. However, realizing the full potential of these advancements requires conscious user behavior and effective laboratory management practices.

Strategies for Balancing Cost and Energy Efficiency

Achieving a balance between the initial cost of a laboratory freezer and its long-term energy efficiency requires a strategic and informed decision-making process. Several factors should be carefully considered to optimize both budgetary constraints and sustainability goals.

1. Assessing the Laboratory’s Specific Requirements

Every laboratory has unique needs. Begin by identifying factors such as:

- Required temperature ranges. Not all samples require ultra-low temperatures; using a -20°C or -40°C freezer when -80°C is unnecessary will lead to significantly higher energy consumption and unnecessary expense.

- Sample storage capacity. The volume of samples to be stored will dictate the required freezer capacity. Over-sizing a freezer leads to higher initial costs and increased energy consumption, while under-sizing can compromise sample integrity.

- Frequency of use. High-traffic freezers may benefit from features that minimize temperature fluctuations during door openings.

This assessment ensures you select a freezer tailored to your operations, avoiding unnecessary costs.

2. Conducting a cost-benefit analysis of different models

Once the laboratory’s requirements are clearly defined, a comprehensive cost-benefit analysis of different freezer models should be undertaken. This analysis should extend beyond the initial purchase price to include estimated lifetime energy costs, based on manufacturer specifications and local electricity rates. Online energy calculators provided by some manufacturers or government agencies can be helpful in this regard.

For example, a slightly more expensive, energy-efficient ULT freezer might have a payback period of just a few years due to significantly lower energy consumption, making it a more cost-effective option in the long run. Consider the potential maintenance costs associated with different models, including the availability and cost of replacement parts.

3. Considering warranties and service agreements

The warranty offered by the manufacturer provides crucial protection against potential defects and malfunctions. Longer warranties can offer peace of mind and reduce unexpected repair costs in the initial years. Service agreements can provide preventative maintenance and priority repair services, potentially extending the lifespan of the freezer and minimizing downtime, which can have significant cost implications, especially in critical research settings.

4. Checking for government or institutional incentives for energy-efficient equipment

Many governments and institutions offer incentives, such as tax rebates or grants, for the purchase of energy-efficient laboratory equipment. Investigating these potential funding opportunities can help offset the higher initial cost of more sustainable freezer models. Resources like the ENERGY STAR program in the United States often provide lists of certified energy-efficient laboratory equipment and information on available incentives.

In conclusion, balancing the cost and energy efficiency of laboratory freezers requires a holistic approach. While the initial acquisition cost is a significant factor, long-term operational costs and sustainability goals must also be considered. By understanding the true costs, leveraging energy-efficient technologies, and adopting strategic purchasing practices, laboratories can optimize both financial and environmental outcomes.

Investing in the right laboratory freezer is not just a financial decision but a commitment to sustainable scientific practices. Thoughtful planning and informed decision-making ensure that laboratories remain efficient, effective, and environmentally conscious in their operations.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.